Unveiling the advantages of stainless steel: Enhancing welding solutions with D&H Sécheron consumables

June 28, 2023 6:38 pm

The unique characteristics of stainless steel make it a preferred material in different industries due to its resistance to corrosion, durability, and hygienic properties. The article highlights the advantages of stainless steel and how D&H Sécheron welding solutions can assist in achieving the best outcomes.

Stainless steel has been a game-changer in the manufacturing industry due to its unique properties, making it the material of choice for many applications. D&H Sécheron Pvt. Ltd, a leading manufacturer of welding solutions, offers a comprehensive range of stainless steel electrodes, wires, and other consumables that cater to various industries’ needs.

Stainless steel, containing 10.5 per cent chromium, resists corrosion by forming a protective oxide layer. Its strength, durability, and aesthetic appeal make it popular in various industries. Due to its chromium content, stainless steel’s inherent corrosion resistance allows it to withstand harsh environments. This makes it an ideal material for applications in the food, chemical, pharma, oil and gas, and construction industries. Corrosion resistance is a crucial reason stainless steel is widely used in the food and beverage industry.

Stainless steel is suitable for various industries with its ongoing advancements and applications. Here are some of the latest news highlights:

• Innovations in Stainless Steel Manufacturing: Continuous efforts by researchers and engineers aim to improve stainless steel manufacturing through innovative techniques and processes. Advancements include leveraging additive manufacturing (3D printing) to produce intricate stainless steel components with enhanced structural integrity and customisation options.

• Sustainability and Recyclability: Its high recyclability rate, ranging from 50 to 80 percent, contributes to a circular economy by reducing waste and conserving resources. Industries are adopting stainless steel as an eco-friendly material choice, aligning with their sustainability goals.

• Stainless Steel in Architecture and Design: These embrace stainless steel for its versatility and aesthetic appeal. From sleek and modern facades to interior applications, stainless steel offers a timeless and elegant appearance while providing durability and corrosion resistance in various environments.

• Stainless Steel’s Role in Infrastructure Development: Stainless steel’s durability and corrosion resistance make it an ideal material for use in bridges, railways, tunnels, and other transportation systems, providing long-lasting and low-maintenance solutions.

• Advances in Stainless Steel Alloys: Researchers are developing new stainless steel alloys with enhanced properties to meet specific industry requirements. These alloys offer improved strength, corrosion resistance, and high-temperature performance for applications in sectors such as aerospace, energy, and automotive.

• Stainless Steel in Medical and Healthcare: Stainless steel is widely used in surgical instruments, implants, medical devices, and equipment due to its biocompatibility, corrosion resistance, and ease of sterilisation.

Role of stainless steel in the welding industry

Stainless steel is essential in welding consumables as it offers exceptional corrosion resistance, durability, and hygiene, making it an ideal choice for various sectors. In chemical plants, where exposure to corrosive substances is a constant concern, stainless steel welding consumables provide crucial protection against chemical reactions. They safeguard the integrity and longevity of equipment used in chemical processing, preventing leaks, contamination, and potential hazards. The outstanding resistance of stainless steel to diverse chemicals establishes it as an indispensable material in the chemical industry.

Stainless steel welding consumables are extensively used to fabricate pharmaceutical equipment and piping systems, ensuring compliance with stringent quality and safety regulations. Stainless steel’s non-reactive nature and ease of cleaning ensure the purity of pharmaceutical products and prevent contamination risks.

With their demanding operating conditions and exposure to extreme temperatures and corrosive environments, refineries rely on stainless steel welding consumables for their equipment and infrastructure. Stainless steel’s resistance to corrosion and high-temperature performance makes it suitable for various refinery applications, including pipes, storage tanks, and processing units. Using stainless steel welding consumables ensures the reliability and durability of critical components in this industry.

D&H Sécheron specialises in providing top-notch solutions tailored to meet the unique requirements of the chemical, pharmaceutical, and refinery sectors. Their reclamation welding consumables are renowned for their high quality and enable cost-effective repair and restoration of worn-out or damaged stainless steel components, extending the lifespan of critical equipment. Moreover, it offers conventional welding consumables that excel in performance and reliability. These consumables are widely utilised in these industries due to their exceptional weld quality, corrosion resistance, and long-lasting durability.

Challenges

D&H Sécheron understands the unique demands of chemical plants, the pharmaceutical industry, and refineries regarding stainless steel welding consumables. Their comprehensive range of reclamation and conventional welding consumables provides effective solutions to tackle these specific challenges.

• Corrosion Resistance

• Hygiene and Cleanliness

• High-Temperature Performance

• Weld Quality and Reliability

• Cost-Effectiveness and Efficiency.

With D&H Sécheron’s welding consumables, these industries can confidently overcome challenges and achieve reliable and efficient welding solutions for their stainless steel applications.

Megaprojects

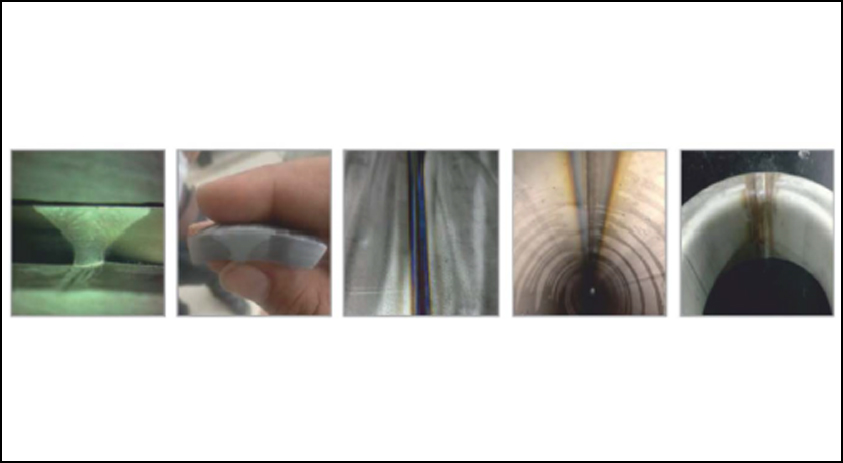

D&H Sécheron’s stainless steel consumables have significantly contributed to major projects such as the HRRL Refinery, the Nigeria Dangote Refinery Project, IOCL Barauni Refinery, NRL Refinery & the Chhara LNG Terminal. Three notable consumables used in these projects are RUTOX-B, SECHERON-308L, & BATOX-B.

RUTOX-B has been successfully employed in the HRRL Refinery project in Rajasthan. This consumable is specifically designed for high-temperature applications and provides exceptional corrosion resistance. By utilising RUTOX-B, the HRRL Refinery project benefited from welds to withstand harsh operating conditions and corrosive environments.

The SECHERON-308L consumable is a stainless steel electrode widely recognised for its excellent weldability and resistance to corrosion. Its use in the Nigeria Dangote Refinery Project ensured the fabrication of high-quality stainless steel structures and equipment that met the demanding requirements of the refinery industry.

Using BATOX-B consumables, Gujarat’s Chhara LNG Terminal project benefited from welds that exhibited superior strength and durability. The advanced formulation and composition of the consumables ensure excellent corrosion resistance, making them highly suitable for the demanding conditions encountered in LNG terminals.

D&H Sécheron’s stainless steel welding solutions

For the development of the steel industry, D&H Sécheron provides various welding consumables.

RUTOX B: A stainless steel electrode producing an extra low carbon 19Cr – 10Ni weld metal with excellent resistance to intergranular corrosion. The weld metal has a higher cracking, oxidation, and scaling resistance at elevated temperatures. Ideally suited for welding stainless steels of similar composition like AISI 304L, 308L, and their equivalents for overlays, surfacing applications, etc.

RUTOX D: A stainless steel electrode depositing an extra low carbon 18Cr – 12Ni – 2.3Mo stainless steel weld metal. The weld metal has excellent resistance to intergranular corrosion even at elevated temperatures. Ideally suited for welding stainless steels of similar composition.

D&H 13Cr: A special flux coated hydrogen controlled electrode depositing 13Cr weld metal. Ideally suited for joining similar alloys, resurfacing valve seats, and steam and gas turbine components. Ideal for joining straight chromium stainless steels.

BATOX B: Basic coated electrode depositing low carbon 19Cr – 10Ni stainless steel weld metal, which has excellent resistance to Intergranular Corrosion. The weld metal has a higher cracking, oxidation, and scaling resistance at elevated temperatures.

Conclusion

D&H Sécheron is renowned for its quality, innovation, and extensive product range in welding solutions. With a commitment to research and development, the company continuously evolves to meet industry demands. By leveraging cutting-edge technology, it provides customers with top-notch welding solutions for stainless steel applications. Their focus on quality, innovation, and technical support makes them a trusted partner in the manufacturing industry.

For more info, visit www.dnhsecheron.com

Source: D&H Sécheron.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi