The Fourth Industrial Revolution is shaping the future of welding

November 1, 2023 12:46 pm

In the ever-evolving world of welding, emerging technologies are reshaping the industry. From automation and environmental considerations to skill development and the integration of data analytics are improving welding outcomes and their impact on the welding landscape.

What are the latest trends and solutions in welding technologies that are transforming the manufacturing industry?

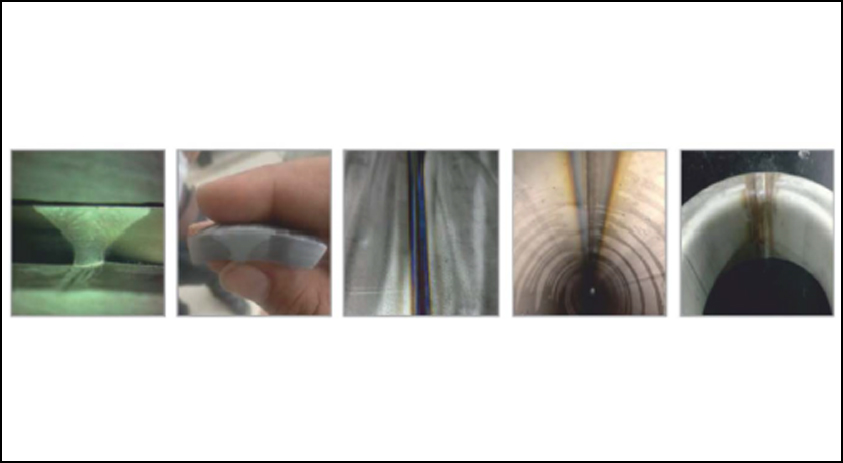

One of the innovative welding technologies making waves in the manufacturing industry is Laser Beam Welding (LBW). This method harnesses a powerful laser to create a focused beam of light, which is used to melt and join metals. The precision of LBW allows for exact control over weld penetration and heat input, resulting in consistently clean welds. Additionally, the decision to use filler material is tailored to each application’s specific needs.

Another noteworthy trend is Hybrid Welding, which integrates various welding techniques, such as laser welding, GTAW (Gas Tungsten Arc Welding), or MIG welding. By combining the strengths of these methods and mitigating their weaknesses, hybrid welding establishes a precise and stable welding process. For instance, laser welding excels at heat control and metal melting, while GTAW or GMAW can introduce additional filler material and effectively manage the weld pool. This highly adaptable approach accommodates a wide range of materials and thicknesses, resulting in high-quality welds with minimal distortion and porosity.

Can you offer insights into the role of advanced materials and techniques in modern welding processes?

In contemporary welding processes, advanced materials play a crucial role in various industries, particularly in applications involving aerospace components. These advanced materials encompass a range of substances, including titanium aluminide intermetallics, nickel aluminide intermetallic alloys, iron aluminide intermetallic alloys, oxide dispersion strengthened (ODS) alloys, metal matrix composites (MMCs), nickel-based superalloys, aluminium alloys (including aluminium-lithium alloys), magnesium alloys, and super martensitic stainless steel.

The aerospace sector, in particular, relies heavily on these advanced alloys for their exceptional properties. While welding has not historically been as prevalent in aerospace manufacturing as in some other industries, there has been a notable increase in its usage over the past decade, thanks to advancements in welding techniques.

When working with these advanced materials in welding, welders face unique challenges. They must carefully manage heat input to prevent material degradation, reduce splatter, enhance control over the welding arc, and ensure the highest possible weld quality. These efforts are essential to meet the stringent demands for performance, durability, and safety in aerospace applications.

How are you addressing environmental and sustainability considerations associated with welding technologies?

Equipment with inverter-based technology is 30 percent more energy efficient than old thyristor-based and transformer-based equipment. Hence, the market has shifted to this latest technology-based equipment.

Electronic components and machine parts adhere to ROHS regulations to safeguard the environment. These regulations prohibit using hazardous materials such as Lead, Mercury, Cadmium, and other ten elements that are harmful to health and challenging to dispose of. Additionally, recyclable plastics are utilised for these components. Engine-driven welding machines must also conform to noise and pollution emission standards established by the Central Pollution Board to minimise environmental impact.

With the rise of Industry 4.0, how is welding technology evolving to integrate with digitalisation and data-driven processes?

The Fourth Industrial Revolution, called Industry 4.0, is ushering in a wave of automation and data exchange within manufacturing processes. This transformation, characterised by the aid of cyber-physical systems (CPS), IoT, cloud computing, cognitive computing, and artificial intelligence, profoundly impacts the welding industry. Increased automation and the integration of data analytics are improving welding outcomes. New welding technologies, driven by AI and precise control, are opening doors in industries that demand top-notch weld quality for the latest and most intricate metals. The industry is set to witness similar strides in safety and quality as it continues to evolve.

Please discuss implementing automation in welding to improve productivity and product quality.

The Fourth Industrial Revolution (Industry 4.0) is the trend towards automation and data exchange in manufacturing technologies and processes, including cyber-physical systems (CPS), IoT, the industrial internet of things, cloud computing, cognitive computing, and artificial intelligence.

The welding sector is undergoing significant changes due to the influence of Industry 4.0. This includes the growing adoption of automation and robotics and the utilisation of data analytics to enhance future welding processes. The integration of AI and emerging welding technologies is also opening up fresh opportunities in industries working with advanced and highly sensitive metals that demand precise control during welding. As the industry progresses, we anticipate innovations in welding methods that will boost safety, elevate quality, and enhance productivity.

Compared to manual welding, automated welding processes can minimise the chance of errors and inconsistent welding, increasing speed, precision, and quality.

How the demand for skilled welders is changing in light of automation and technological advancements?

The need for proficient welders will remain constant, even with automation and advanced welding techniques. Instead of focusing solely on improving welders’ general manual welding skills, customised welding training programs are designed to address the precise requirements of individual welders or specific organisations. These programs aim to transform participants into experts in their field. These specialists can fine-tune automated welding stations’ fundamental parameters and timing settings. This ensures a consistent quality of the finished product, reduces the need for post-weld cleaning, and facilitates seamless parts fitting for complete assemblies or subassemblies.

What emerging welding technologies and applications deserve attention in the near future?

Welding Cobots or collaborative welding robots are designed to complement human welders during the welding process. Equipped with sensors and programming, these robots work in tandem with human welders without the need for safety barriers or enclosures. They help with repetitive or physically demanding aspects of welding, significantly enhancing safety and ergonomics.

Welding drones, or unmanned aerial vehicles (UAVs), are equipped with cameras, sensors, and robotic arms to conduct welding duties and inspections. They excel in accessing hard-to-reach or hazardous locations, such as tall buildings, bridges, or offshore oil platforms, where human welders face the greatest risks. Operated remotely by humans, these drones can monitor and adjust the welding process. Their use removes the need for scaffolding or other access equipment, saving time and money.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi