What is Metal Injection Moulding?

April 11, 2018 6:30 pm

Explaining the key advantages of metal injection moulding over conventional technologies.

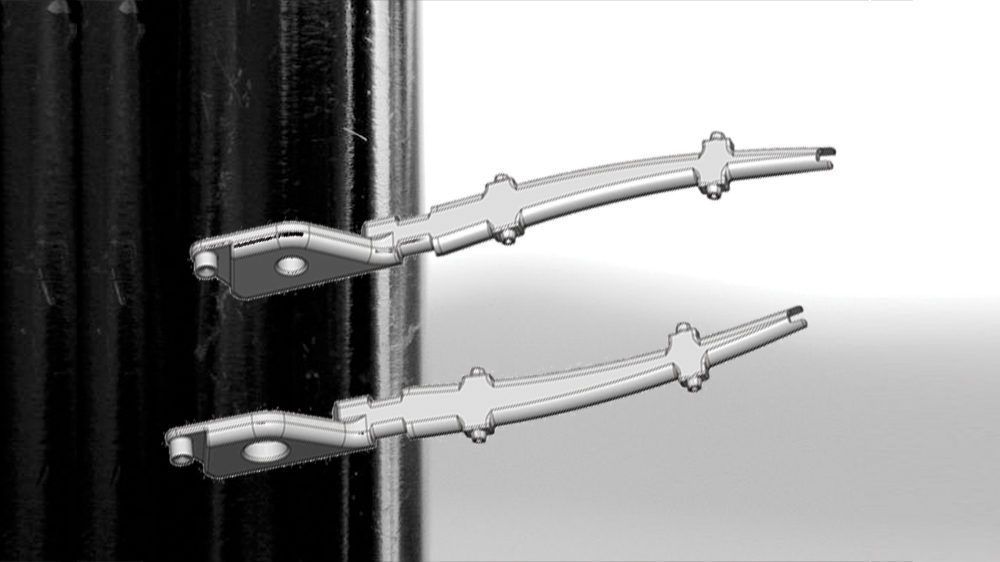

The inclusion of Metal Injection Moulding (MIM) in the die and mould industry is an imperative capability in producing complex shapes at large scale in cost effective way. In its core, it involves the processing of fine metal powders through a binder (custom built) and then getting it fed into multiple cavities at its injection moulding process. Hence, here we will be discussing how efficient is metal injection moulding in comparison with conventional technologies.

MIM: A fabulous process to make smaller finished products

Nishant Shah, Director – Engineering, Imaginarium India Pvt Ltd, says, “MIM has been around for quite some time but is still not as popular as die casting or investment casting or sand casting. MIM is a fabulous process to make smaller finished products, typically up to 100 gms, rather than conventionally making them using different technologies and then assembling it as one. It still remains one of the lesser known processes but an important one.”

Benefits to have fewer manufacturing processes

Vineet Seth, Managing Director – South Asia and Middle East, Mastercam India Pvt Ltd, informs, “It is always beneficial to have fewer manufacturing processes or setups for parts with complex geometries. MIM or powder injection moulding as it is commonly known, takes a well-established process of plastic injection moulding and applies it to metal powders, less than 20 microns in size, with binders. The result is a very efficient way of producing metal compacts for small and intricate components which can be sintered in a furnace to quickly and efficiently produce the finished metal components.”

He adds, “Most of the components go through a tertiary finishing process, before they are put to use. This process is ideal for manufacturing surgical, electronic and smaller consumer parts.”

Advantages of MIM

MIM is capable of producing a wide range of geometries

MIM has some great advantages as compared to other processes. First and foremost, one can make parts in ferrous materials, the most common materials being low alloy steels, tool steels, stainless steels, magnetic alloys and bronze. Shah informs, “MIM is capable of producing a wide range of geometries and so is utilised in many industries. The accuracy and speed of the process make it ideal for manufacturing components for the aerospace, automotive, medical, dental and consumer electronic industries. The high pressures used in this process ensure good surface finish, fine reproduction of details and of course excellent repeatability. Also the MIM parts are resilient, ductile and strong which makes them easier to do post process on, like other metal parts.”

Provides high equipment productivity compared to conventional tools

Seth informs, “Using MIM one can avoid machining processes like threading, grooving, gripping patterns, insignias, emblems and pores or lubrication channels. It also provides high equipment productivity compared to conventional tools, offers a higher material utilisation rate, reduces scrap and waste – all while providing decent tolerances and good surface finish.”

He added, “A key advantage of MIM is the elimination of multiple manufacturing setups and processes for small and intricate components, thereby reducing the time to market along with a reduced per component price. It is also a relatively non-polluting and a cleaner method.”

MIM supports mass production of tiny materials

MIM supports mass production of tiny materials with unlimited shape and micro geometric nature without compromising high production volume by adapting comprehensive multi cavity tooling with even less than 10 seconds if proposed. The interesting point in the technology is all about the size of the powders used. As the feedstock generally available for MIM is even about 20 microns level, it could ensure ultra flexibility at any challenging shapes against other conventional technologies in the market.

MIM ensures cost effective production streaming at large scale platforms

The moulding scope of wide range of alloys and pre-alloys are possible through MIM, it also extends an additional advantage of minimum finishing time. K. Manickam, Managing Director, CAD Macro Design and Solutions Pvt Ltd says, “MIM ensures cost effective production streaming at large scale platforms with minimum wastage and highest usage of materials which usually touches 98 per cent most of the times based on the design and tooling strategy. Beyond anything, MIM stands unique while processing high temperature metals as the applied temperate is custom regulated by the relevant binder in the process. By and large, MIM sustains a large scale production support up to the scale of 1,50,000 to 2,00,000 parts per day using multi cavity system which is relatively a big number by deserving high accuracy and ultra precision as its key driving factors.”

Disadvantages of MIM

Few potential defects

Shah states, “There are a few potential defects in the process like sink marks, weld lines and flash. But unlike plastics metals can be reworked, ground and polished to improve surface finish. Downside is that the parts have to be typically below 100 gms or so, hence limiting the process to manufacture larger components.”

Higher investment and initial costs

Seth explains some of the disadvantages of MIM as:

• Process becomes less and less favourable as the component size increases.

• Higher investment and initial costs makes it a slightly difficult process to adopt by most manufacturing setups.

• MIM powder costs tend to be expensive in comparison to powder metallurgy.

• Suitable for larger production runs as opposed to short ones.

• The most suitable component size for this method is between 10-20 mm.

Demands expensive finishing compared to conventional technologies

Manickam observes, even though MIM stands supportive for large scale production of tiny and complex parts in a production flow, it becomes expensive at initial cost and investment proportions of bigger parts and when it becomes lower scale. He adds, “Same way, the material cost of the MIM process becomes very high during the production of large size components as the effective utilisation of finest powders are negatively proportionate for higher size finishing until and other wise there is a scope to recycle. It is also a critical setback in MIM that larger size outputs from the process demands expensive finishing compared to conventional technologies”.

MIM is a fabulous process to make smaller finished products, typically up to 100 gms, rather than conventionally making them using different technologies and then assembling it as one.

Nishant Shah, Director –Engineering, Imaginarium India Pvt Ltd

A key advantage of MIM is the elimination of multiple manufacturing setups and processes for small and intricate components, thereby reducing the time to market along with a reduced per component price.

Vineet Seth, Managing Director – South Asia and Middle East, Mastercam India Pvt Ltd

MIM stands unique while processing high temperature metals as the applied temperate is custom regulated by the relevant binder in the process.

K. Manickam, Managing Director, CAD Macro Design and Solutions Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi