Electro Chemical Machining – Solution for Manufacturing Challenges

August 14, 2017 12:42 pm

With increasing demand of precision parts; manufacturing process, especially for complex profiles and intricate shapes is becoming more and more challenging. Electro-Chemical Machining (ECM) is an answer to many of such challenges

Market reasons to use ECM

Electrochemical machining (ECM) is a manufacturing process of removing metal by an electrochemical process and can be used for machining both external and internal geometries. It is generally recommended for mass production and is suitable for hard and exotic materials such as titanium aluminides, Inconel, and high nickel, cobalt, and rhenium alloys. ECM is also suggested for materials and / or shapes those are difficult to machine using conventional manufacturing methods. As every process will have limitation, ECM too has and is limited to electrically conductive materials. ECM can cut small or odd-shaped angles, intricate contours, or cavities in hard and exotic metals.

ECM is often characterised as “reverse electroplating”, in that it removes material instead of adding it. ECM cutting tool is guided along the desired path close to the work but without touching the piece. Unlike EDM, no sparks are created hence it is also termed as cold process. High metal removal rates are possible with ECM process and without transferring thermal or mechanical stresses to the part. With proper parameters, a mirror like surface finish can be achieved.

In the ECM process, a cathode (tool) is advanced into an anode (workpiece). The pressurised electrolyte is injected at a set temperature to the area being cut. The feed rate is the same as the rate of “liquefication” of the material. The gap between the tool and the workpiece varies within 80–800 microns (0.003”–0.030”). As electrons cross the gap, material from the workpiece is dissolved and desired shape in workpiece is formed. The electrolytic fluid carries away the metal hydroxide which is formed during the process.

Advantages of ECM

• There is no contact between tool and work piece hence does not generate wear to the tool.

• No mechanical stress is induced to the work piece.

• The metal removal process is cold – no heat is generated.

• The process works on almost all metals and alloys.

• The metal removal process can be controlled by the cathode

• ECM is very efficient in deburring of edges internal and external of components as in hydraulic blocks, valves, crank-shafts and many other parts

• ECM works equally good on soft and hard metal.

• ECM works fast, deburring operations can be done within seconds.

• EC Deburring does not generate secondary burrs, this is an important on many critical parts, especially on DFI system parts, crank shaft etc

• Specially designed power supply system controls the accuracy and repeatability

Process limitations

• Only applicable to electrically-conductive materials.

• Post-process treatment required due to the corrosive salts.

Proven solutions

There are numerous proven solutions to wide variety of components. A couple of examples are:

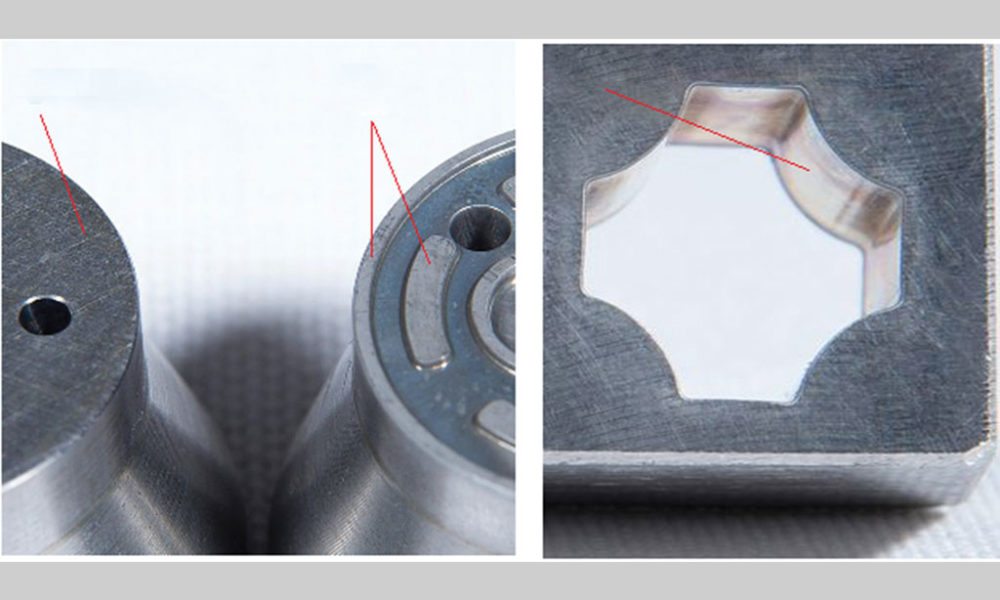

ECD of edges of Common Rail Distributor Pipe operated at pressures exceeding 3000 bars (43,000 PSI). ECD results in burr free and tangentially rounded internal edges of R ~ 500µ

This would be mandatory requirement for Euro VI compliance parts to avoid point of stress concentration, resulting in premature failure

Dynamic ECM or PECM

PECM (Precise Electro Chemical Machining) follows the same principle as ECM does i.e. removal of material from the work piece. However, PECM uses a non-static Cathode which travels into the Anode constantly maintaining very tiny (usually <10µm) gap distance over the complete cycle time.

Precision in the part being processed is function of the tiny distance maintained between cathode &anode, speed of travel and cathode shape

PECM is very much suitable to machine complicated profiles / shapes on the parts. Eventually in some cases PECM replaces many operations e.g. multi axes CNC machines, deburring and polishing with single operation.

MachTools TechnoServe P Ltd is focused on offering surface finishing and surface treatment solutions in collaboration with OEM from Europe and USA. For ECM technology, the company is supported by stoba Sondermaschinen GmbH (www.stoba-memmingen.de ) which offers a wide range of solutions in ECM and PECM technology. For more information, contact at sales@machtools.in

Composed by:

Ashok Johri

Vice President – New Business Development

MachTools TechnoServe P Ltd, New Delhi

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi