Cobots: A Helping Hand

August 14, 2017 2:37 pm

Cobots give manufacturers the opportunity to grow in measured steps so they can maintain competitiveness in a global landscape without taking on an undesired undue risk.

Industrial automation has always been part of manufacturing industry on limited basis. Over the past few decades automation has become a necessity in manufacturing industry due to global competition. This has helped in efficient manufacturing processes and in mass-production of goods. Automation is becoming inevitable globally in the manufacturing industry today.

All industrial processing systems turned to automation that is driven by the need for high accuracy, precision and performance of industrial processes. Thus, automation became an indispensible part of the manufacturing industry.

Automation in its broadest sense has expanded from its original industrial manufacturing base to laboratories and businesses. The application of robotics and automation has been successfully achieved in a wide range of industries dealing with well defined processes and products like the manufacturing industry, FMCG, automotive industry, healthcare industry, pharmaceutical industry, to name a few.

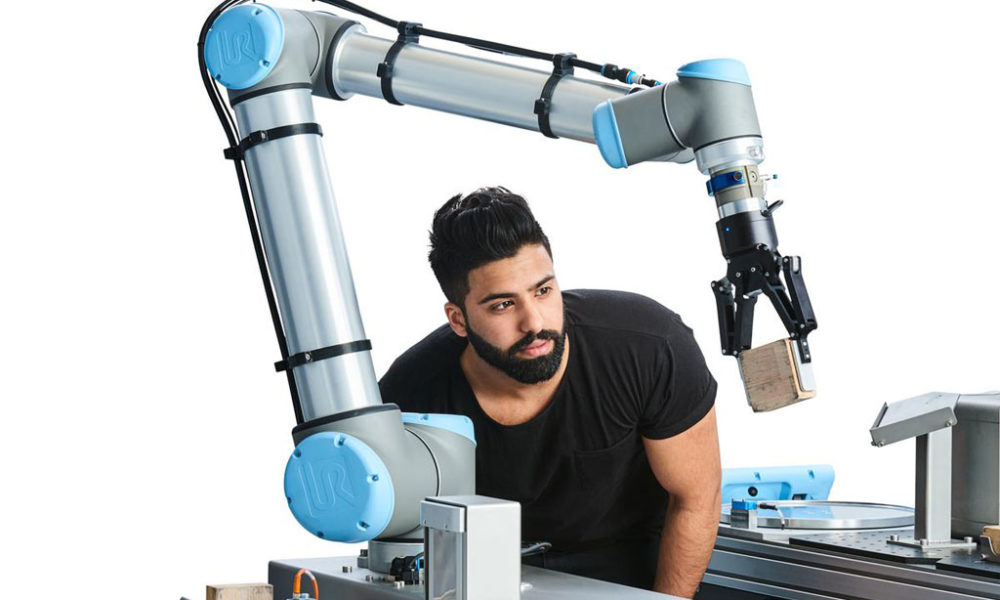

With this idea of higher production rate and the need for human interaction with machine automation, the Collaborative robots were first developed in 2008 by Universal Robots. The human-robot collaboration is different from traditional robots. The idea is for humans and robots to be inter-dependent and achieve what each of them does best. There are a few things that must be done manually, whereas the accuracy, precision and mass production at higher efficiency is taken care of by the robots.

With the idea of higher production rate and the need for human interaction with machine automation, the collaborative robots were first developed in 2008 by Universal Robots. Universal Robots is one of the leading manufacturers of advanced user-friendly and light industrial robotic arms from Denmark. Their latest technological advancement in collaborative robots or ‘Cobots’ was brought out in the international market with a peculiar intention which is in line with Industrial 4.0 which is in sync with the automated revolution in the manufacturing industry.

This approach is particularly appealing to the Indian manufacturing industry because labour-intensive conditions and the collaborative robots together can help the Indian market achieve the best of both worlds by making precise use of this distinctive technology. This has been seen with some of the collaborators of Universal Robots, which include Aurolab and Bajaj Auto Ltd.

Universal Robots have been working with Aurolab which is associated with the healthcare centre. The labour force at Aurolab actually increased from 15 to 700 and production improved from 150 to 10,000 Intraocular Lenses (IOL) per day. They are exporting to over 130 countries due to superior quality of their lenses. Aurolab have seen a 15 per cent increase in the annual product output. Aurolab is associated with the Arvind Eye Care Systems and have provided them with co-bots that have increased affordability helping people regain vision at lower cost, and has considerably reduced the power consumption and quality problems.

Bajaj Auto Ltd saw a gradual rise in the productivity and efficiency in their production. It also increased the productivity of their employees along with their product quality after associating themselves with Universal Robots. They have deployed over 100 cobots since 2010 and are now the 3rd largest motorcycle manufacturer in the world. They are of the view that the added benefits of the co-bots are easy use, very low annual maintenance and higher energy efficiency.

Robotic arms like the Universal Robots’ UR3, UR5 and UR10 are inexpensive, light weight and easy to program. This enables them to assist with a broad spectrum of food industry applications. This enabled them work seamlessly with the food manufacturing industry.

UR3

The UR3 is a flexible table-top robotic arm that has a payload up to 3 kgs with a 360 degree rotation on all joins and an infinite rotation on the end joint. It can be used for simple tasks like picking, placing and assembling.

UR5

The UR5 is ideal to optimise low-weight collaborative processes, such as: picking, placing and testing, with a payload of 5 kgs. It has a reach of 850 mm, thus, freeing the staff to undertake different tasks.

UR10

The UR10 is the largest industrial robot arm, with a payload of 10 kgs. It has been designed for bigger tasks that require precision. Heavier-weight collaborative processes, such as: packaging, palletising, assembly and pick and place are all well suited to the UR10 industrial robot. With a reach radius of up to 1,300 mm, the UR10 industrial robot is designed to be more effective at tasks across a larger area.

Each of these arms have unique functions that can assist the workforce with varies tasks. They become the third helping hand in production, constituted to take over mundane, repetitive, physically demanding work that requires precision and efficiency. They also have the fastest payback period which makes them economical.

Three robotic arms from Universal Robots namely UR3, UR5 and UR10 can incorporated into the various processes so that engineers could easily adapt the software to the specific needs for the required tasks. The easy programming, installation and collaborative nature of the industrial robot arms allow them to work side-by-side with the workforce for efficient, high-quality medicines.

Collaborative robots create remarkable advancements in industrial processes. They can be programmed by operators adding tremendous flexibility to meet human problem solving needs. Cobots give manufacturers the opportunity to grow in measured steps so they can maintain competitiveness in a global landscape without taking on an undesired undue risk. Collaborative robots can essentially be termed at the ‘third hand’ that helps the workforce in carrying out monotonous tasks, as Universal Robots believes in giving back power to the worker. The cobots can be seen as a step forward in widening the scope of Indian manufacturing industry, not only in quantity but also quality.

A new generation of collaborative robots can usher in an era of shepherding robots out of their cages and literally work hand-in-hand with human workers who train them through physical demonstration. The collaborative robots were in line with Industrial 4.0 and have managed to fulfil the idea of humans and robots co-existing in a workplace. In the era of mass production, Universal Robots focus on mass personalisation. Their emphasis is on increasing not only the production but also precision, efficiency, quality and the productivity of the industry.

The heavy industries use caustic chemicals and high temperature processes which can be hazardous for humans. The cobots can work under such conditions without safety concerns, reducing the risks to employee health at workplace. This makes the workplace a co-habitable environment for technology and humans.

Thus, the incorporation of collaborative robots will be a timely introduction to revolutionise the Indian industries which will bring optimisation of processes, reduce waste, improve yield in production, with higher efficiency and precision. The functions that have already embraced automation will continue to prevail with incremental improvements from the normal cycle of technological innovation. Areas that are likely to witness quantum leaps will be in the integration between development work and manufacturing, efficiency and optimum utilisation of robotics in the industry.

For more details, visit www.universal-robots.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi