Moulding the die & mould making industry

September 24, 2015 10:51 am

Buoyed with the industrial development, the Indian die and mould making market expects exponential growth. However, adoption of innovative technologies will determine the fortune.

The die and mould making industry in India has evolved over the years and today competes with its global counterparts. With an increasing demand from industries such as automobiles, auto components, packaging, plastics, electronics, electrical, healthcare and machine tools, there is a huge opportunity in the die and mould making industry in India.

The opportunities in the die and mould industry are enormous in terms of domestic as market expansion. S. Muthukumar, Vice President, CAD Macro Design & Solutions Pvt. Ltd. says, “Major customers in India look import as an immediate and risk free option when it comes to die and mould requirements to them. This could be very much replaced by Indian die-mould vendors if they could bridge the critical gaps existing in the technology, operational and delivery systems. In most of the cases, integrated resource management and better tool room management systems could play vital role in bridging such gaps and could bring lot of revenue base for the local market.”

The Indian die and mould industry is mainly dependent on the automotive industry and follows its growth pattern. According to S Subbarayan, Deputy General Manager – Die and Mould, Makino India, “With the globalisation of the Indian automotive industry, we are seeing a qualitative change in the type of moulds and also a huge pressure on deliveries. Accuracy and finish requirements are getting tighter and this demand for better manufacturing capabilities within the die and mould community in India. With most of the automotive OEMs working aggressively on newer products, we find most of the tool rooms are busy and expanding.”

High-quality and high-precision are the buzzwords of any die and mould business. The tool room industry is undergoing a change in manufacturing practices. Earlier, only few important components were manufactured using the CNC machine, now the industry is switching over entirely to CNC to gain a competitive edge. Mitsubishi Electric emerges as one of the leading CNC controller suppliers in this segment. Mitsubishi Electric CNC products are engineered with cutting-edge solutions and technologies to meet the highest quality requirement of the precision industries.

Offerings to the die and mould makersMitsubishi Electric offers new generation controllers that are developed with many standard functions to suit the current market requirement and excel in years to come. A number of specially-developed control functions, such as “SSS” (Super Smooth Surface), the high-grade Mitsubishi Electric CNC M70/M700V series deliver SSS control. SSS flexibly supports various compound machining including multipart system/multi-axis machining centres, milling and hobbing. Mitsubishi Electric provides the control necessary for high-performance milling. With fully developed 1 nano precision – machining technology, range of special high-speed, high-accuracy functions all come as standard, resulting in faster block processing time and ensures the highest level of precision therefore resulting in shorter machining time. This functionality improves the accuracy and better productivity in machined parts.

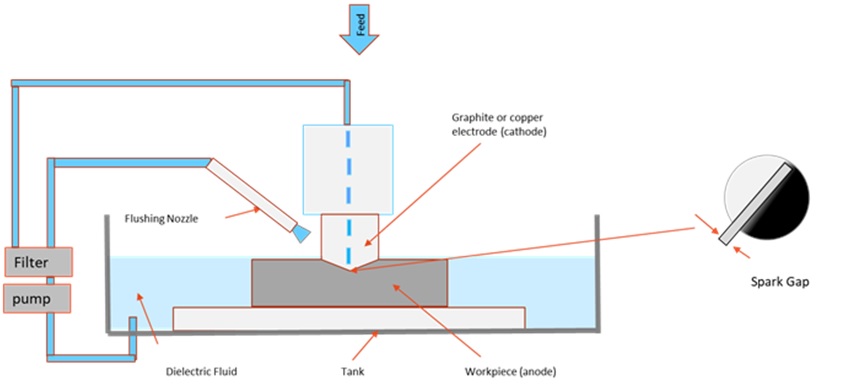

Makino has always worked towards providing technology and solutions rather than just sell machines, informed Mr Subbarayan. He adds, “Die and mould industry is one of our key focus market and we have always been developing several technologies and products to serve the specific challenges faced by this industry.” Makino’s product range from vertical and horizontal machining centres to CNC sinker and wire EDMs has a wide range of applications. “High speed milling technologies complemented by innovative EDM solutions from Makino have transformed the way dies and moulds are manufactured globally,” Mr Subbarayan claims.

Being one of the pioneers in the tool room management software vertical, CAD Macro Design & Solutions Pvt. Ltd. offers the complete range of the CAD / CAM products in the segments of wire EDM, CNC milling, press tool design, CNC lathe and integrated tool room management ERP called – shop plan. “The greatest advantage of our solutions is that it has been well accepted by all the standard OEMs as well as large scale customers in the market. This uniqueness has made us to win and sustain a domestic client base of more than 600 customers across PAN across the 8 products,” Mr Muthukumar avers.

CAD Macro Design & Solutions started with single solution to address the wire EDM market 8 years ago, that too with 2D options. But, by taking the technology improvements in the OEM side and client requirements into account, the company started expanding its solution bandwidth with 3D options and has become a turnkey solution provider for the complete machine floor over a period of time. “We also could reach out the entire market as platform integration partner in terms of our shop plan, the tool room management integration software. Our commitment to excel continues, improvement and sustained customer satisfaction are the key driving factors of our growth,” added Mr Muthukumar.

Technologies shaping the die and mould making industryWith increasing complexity of the product profiles and higher accuracies, coupled with demand for extremely fast deliveries, the industry needs to work on highly efficient processes and machines. Minimising the number of machining setups and processes is the way forward to achieve these goals. The usage of 3+1 and 3+2 axis machining in the machining centres have dramatically reduced the machining time and resulted in improved accuracies and surface finishes. Improvements in the CAM technologies and high performance cutting tools have also greatly improved milling capabilities to achieve near net shape of the core and cavity in terms of finish and accuracy. EDM technologies are also evolving rapidly to meet the growing demands for shorter machining times and reduced human intervention. “Adaptive control technologies on EDM machines have greatly enhanced machining efficiency and led to a very high level of automation,” opines Mr Subbarayan.

Lot of technologies are coming up in the die and mould industry at par with other sectors. At the same time, improved tool room integration and monitoring solutions, automation of machine floors, deploying human machine interface models at the production side, improving quality monitoring systems and including possible 3D and simulation scopes in the CAM segments are the few key initiatives to be accounted in the technology improvement area of die and mould industry.

“Apart from technology improvements, systems and processes focusing on predictive and proactive machine maintenance, closer observations on manpower ratio, utility vs life parameters of die moulds are giving analytical strength to this industry compare to its early stage manually driven leadership thereby increasing the overall productivity,” observes Mr Muthukumar.

Mitsubishi Electric offers the technology of “SSS” control to provide an optimal speed control function for machining die and mould with smooth surface. In CAM to create a machining program, the motion curve of the tool relative to the work piece is calculated by approximating the minute line segments. Therefore small error is more or less included in the data of minute line segment. In CNC, it’s essential to have the process of determining the rate at which it moves, according to the shape in order to maintain the trajectory accuracy. If some errors are included in the instruction shape, it is difficult to calculate the accurate determination of the appropriate speed movement. Mitsubishi Electric thinks in a different way from such shape correction in which potential risks are hidden. In the process of determining the movement speed depending on the shape, the process is not affected by the error contained in the directive shape and it can generate a stable and optimal pattern of speed, it is possible to obtain a smooth cutting result even if the pattern and magnitude of the error included in the instruction by the path shape are different. The “SSS Control” was developed so as to realise the speed control method in this way. The following original processing modes are adopted in SSS control:• The global shape judgment based on prediction of instruction form determines the optimal feeding speed.• Efficient acceleration and deceleration without waste even in shape• Processing a uniform that does not depend on the speed and shape instruction

——————–The greatest advantage of our solutions is that it has been well accepted by all the standard OEMs as well as large scale customers in the market.

S. Muthukumar, Vice President, CAD Macro Design & Solutions Pvt. Ltd.—————————————-With the globalisation of the Indian automotive industry, we are seeing a qualitative change in the type of moulds and also a huge pressure on deliveries.

S Subbarayan, Deputy General Manager – Die and Mould, Makino India

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.