Speeding development cycle with 3D Printing

October 17, 2019 12:05 pm

Supreme Industries Limited offers a wide range of plastic products with a variety of applications in molded furniture, storage and material handling products, PE (Polyethylene) films and products, performance films, industrial molded products, protective packaging products, composite plastic products, and many more. Supreme Industries Limited-Supreme (1942) is one of the leaders in India’s plastics industry. The company handles a volume of over 320,000 tons of polymers annually.

Using technology to improve the prototyping process

Supreme’s new product development initiatives are key to their success. The company depends on cutting-edge technology for a fast product development cycle, ensuring on meeting time-to-market deadlines and product quality benchmarks. Till 2015, the company followed manual prototyping for product development which posed a unique set of problems. Manual prototyping is prone to human error, and necessitated rework in many instances. This increased product development time and cost estimates, upsetting the company’s time-to market targets.

To avoid the unpredictable nature of manual prototyping and add stability to the process, Supreme moved to standardise its prototyping efforts. The company also wanted to maintain design confidentiality by keeping product design in-house. To achieve these objectives, the company invested in 3D Printing, which also promised to reduce product development time and cost, and improve quality. To select the appropriate 3D printer, the Supreme Design Center team established specific criteria. 3D printed parts needed to be tough, have a smooth finish and fit seamlessly with mating parts.

Preventing prototyping obstacles

Since the installation of Stratasys uPrintSE Plus 3D printer, Supreme’s design department uses it extensively to fulfill various prototyping needs. The team uses 3D Printing for design verification, marketing approvals of new products, and assistance in mold and tool development. By printing dimensionally and geometrically precise prototypes, the 3D printer also improves internal communications and client demonstrations.

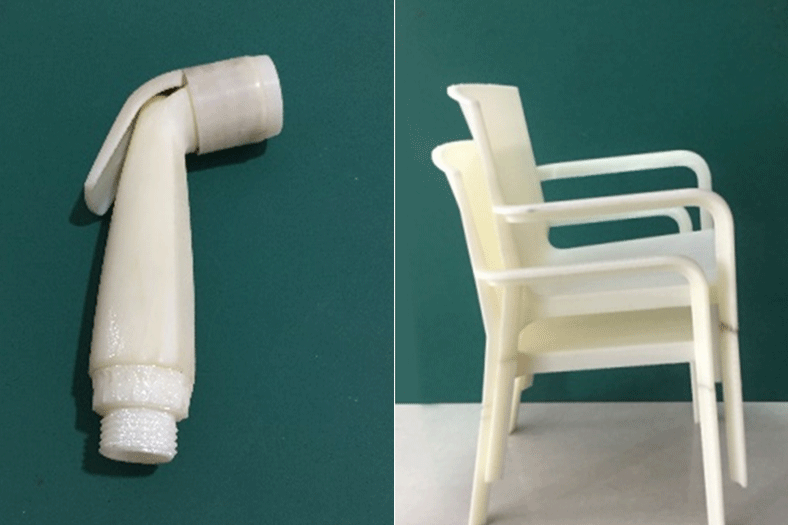

Supreme uses ABS material for all its prototypes as it gives the required strength for functional testing. Also, the marketing team can easily demonstrate these prototypes to their clients and better explain product functionality. The printed parts are accurate and display fine product features, key benefits for proving the product’s intended fit and function. The team also uses the 3D Printer to make butterfly valves, furniture parts and taps. They subject all printed parts to stringent functional tests for performance validations. With in-house 3D printing, Supreme has been able to utilise the machine with ease and speed. On average, the team prints a prototype only in three hours, which used to take three days through the manual process. With the hassle-free, fast, and user-friendly 3D printing process, the team saves 90 per cent time and produces durable, high-quality parts ideal for product design validation.

The time comparison between 3d Printing and conventional prototyping methods

Method for prototyping Time

Past (Without 3D printer) 3 Days

Present (With 3D printer) 3 Hours

Savings 90% (overall)

A prototype water spray nozzle 3D Printed in ABS material to validate the nozzle size and flow capacity to withstand the speed of water

These stacking monobloc chair models were 3D printed in ABS material to check the viability of the design

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi