Sheet metal forming at its finest form with 2D, 3D technologies

January 12, 2021 5:45 pm

Industry leaders discuss, India looks to be definitely in strong transition phase in sheet metal manufacturing activity. Overall approach has been changed from product oriented buying process to Solution oriented process. India is for sure emerging as major manufacturing hub for sheet metal activity with evolving adaptation to global technology and know how.

Global metal forming market growth

Even during COVID times, sectors like Agricultural machinery, Construction machineries, Infrastructure, Railways and Retail are growing significantly. India being one of the most populousand developing nation the demand for mechanisation of Agriculture and Infrastructure, housing will continue to grow at fast pace. Today approx. 16 percent of GDP of India comes from Agricultura. Continues, Niraj Seth, President, Amada (India) Private Limited “The demand for sheet metal fabricated components right from infrastructure to house hold item will need big investment into Sheetmetal fabricating machineries.” Considering last 3 years activity more over the precision level, faster throughput and small batches has been the key criteria in Indian sheet metal sectors.Niranjan R Manjrekar, General manager- India operation, LVD Strippit India PVT LTD, adds, “This all elements demands not only good machine equipment but also effective solution in processing the parts for machining and this is where the demand for good software and intelligence in database comes in picture with IOT platform.” Where as explaining the market potential, Dinesh Aggarwal, Joint Managing Director, Panasonic Life Solutions India, said, “India has a very low per capita consumption across categories, products, and services. The growth in consumption will galvanise the growth of the entire supply chain including allied services. All companies across the world are looking for markets that can offer steady growth and good returns. While these manufacturers will need to invest in sales and distribution infrastructure, brand building, etc.; local product development and local manufacturing will ensure their sustained success.”

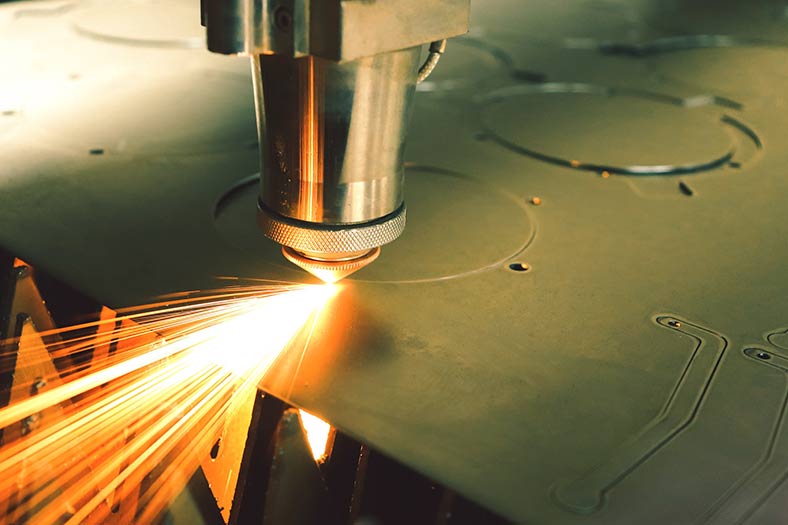

2D, 3D being implemented in sheet metal manufacturing

The laser cutting process is being used for sheet metal fabrication for quite some time due to its unique advantages over Punching process. We were first to introduce our production laser cutting machine for sheet metal fabrication in year 1980.

The technology then was mainly focussed on CO2 laser which has its unique merits and demerits. To overcome demerits of CO2 laser now Fiber Laser source is being popularly used to process sheet metal ranging from 0.5 to 25mm thickness. The biggest advantage of Fiber laser over CO2 Laser is Low power consumption, higher productivity and lesser cost of maintenance.

Seth elaborates, “Next we will see LBC technology from Amada. How to use the fiber laser beam is going to be the next change.Sheet metal is all about realisation of 3D form and hence working with 3D technologies has been unavoidable.” In forming process you need to able to visualise the methods and ways to produce the 3D part very precisely and only a real time database and advanced programming software by which end user can process it with highest accuracy on Machine without error and with faster switch over to another form or profile with try and error. Not many machine tool builder has such solution and hence it is very important to consider this part while making decision.

Manjrekar adds, “At LVD we have been always one step ahead on adaptive approach consisting of High quality Machine tool along with Innovative and efficient programming software solution compatible on IOT platform.”

Latest technologies and machineries

Mature sheet metal fabrication market like Japan, Europe and USA nowadays are considering Combination machine with Automation for expansion. Seth adds, “A combination machine can process practically anything by combining advantages Punching and Laser process. This helps to bring down production cost per piece.”

In Press brake flexibility and faster switch over between part production is the key and that’s what we do with our Adaptive bending technology of Easy form series machine with automation feasibility. Manjrekar continues, “High power laser are more aspired for production rate and speed and hence automation becomes integral prat of this solution. Faster change over to next sheet is critical and not possible without material handling solution. We have been very aggressive in offering variety of Laser automation possibility to the need of the Customer. Sheet metal forming technology is evolving every stage and at LVD we had been busy in many innovative product launch this year in Laser cutting and Press brake segment.”

Appreciating the current leadership’s approach, he adds, “The political leadership in India, especially for past 7 years particularly has displayed an unwavering will to improve the infrastructure, enhance skill level, ease labour laws, eliminate corruption, ease the approval process for FDI and ease the establishment of new businesses which has given a lot of confidence to the global political and industrial leaders. The banking system in India, though getting repeatedly battered in terms of bad debts, has shown an overall resilience and controls therefore financial stability, which is not seen in many countries across the world; including some of the developed nations.” Intelligent Automation which includes joint free processing and sorting helps to reduce dependency on manpower to a great extent. Most of this are for high end precision and higher throughput at the same time on lesser ownership cost.

Latest product and technology offerings

Sethexplains Amada’s ground work, “We have installed Combination machine Model LCC1AJ with Automation at our Bangalore Technical Centre. This setup takes care of auto sheet storage, punching, laser, Taping, forming, joint free operation and part sorting with least manual intervention.

We have also setup a Robotic Hybrid drive Press Brake that can fold the flat sheets into desired component without bending operator.”

Where as Manjrekar talks about LVD, “Our new product Ulti-Form takes the best of LVD bending technology and combines it with fast robot and press brake programming, optimised input and output capacity, and a universal gripper – to create a unique system that efficiently bends parts. Ulti-Form takes bending automation to the maximum, delivering high productivity in a compact space.”

The next big thing

Seth while talking about Amada said, “AMADA’s revolutionary Locus Beam Control (LBC) to achieve infinite locus patterns — ensuring optimum fiber laser beam shape control for each specific cutting application. LBC technology achieves unprecedented high-speed and high-quality cutting — up to 3 times faster than a conventional fiber laser.

AMADA has also developed a high-brightness fiber laser oscillator to maintain optimal quality of the high-energy density laser beam. The combination of LBC Technology and a high-brightness oscillator set a new world standard for fiber laser cutting speed and quality.”

Dinesh Aggarwal, Joint Managing Director, Panasonic Life Solutions India

The growth in consumption will galvanise the growth of the entire supply chain including allied services.

Niraj Seth, President, Amada (India) Private Limited

Mature sheet metal fabrication market like Japan, Europe and USA nowadays are considering Combination machine with Automation for expansion.

Niranjan R Manjrekar, General manager- India operation, LVD Strippit India PVT LTD

India looks to be definitely in strong transition phase in sheet metal manufacturing activity.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi