Milling of three different rail profiles

November 11, 2019 4:45 pm

Compared to grinding, the high-speed re-profiling of railway lines represents significant time and financial savings. Specially designed trains, operating at a constant speed of 700 meters per hour, machine the existing track profile. By removing millimetres of metal from the damaged surface, the track is restored to its original condition. This, on the-move application, requires specialised equipment to achieve optimum results, such as ‘train machine tools’ designed to carry dynamic rail milling cutters and inserts.

Global cutting tool manufacturer Dormer Pramet works in partnership with several high-speed milling machine manufacturers to delivery key projects around the world. One of these projects includes the milling of three different rail profiles for a customer in the Netherlands.

Dormer Pramet’s 600mm diameter dynamic rail milling cutter was able to machine the combined profile (60E1, 54E1, 46E3 1:40) and another profile 54E5 1:40, without having to change the inserts. Using the same cutting tools across several profiles is hugely beneficial as it saves both time and costs, reducing the number of tool change-overs.

Tomas Hantek, Application Manager for railways at Dormer Pramet, said: “As with all railway projects, each application is different from the next, so we regularly tailor our products to meet the need of the customer. It is very important we work closely with the machine tool manufacturer and rail organisation to identify where adaptions need to be made to achieve the desired results.”

The development of new rail technology is constantly taking place and modifications are needed on both sides to optimise the match between the machine and cutting tool. Dormer Pramet has adapted its popular dynamic milling cutter in various sizes, from 300mm to 900mm, with plans to develop a 1,400mm diameter version in the future. At present, Dormer Pramet has more than 50 dynamic rail milling cutters out in the market, including in the Netherlands, Germany and Poland.

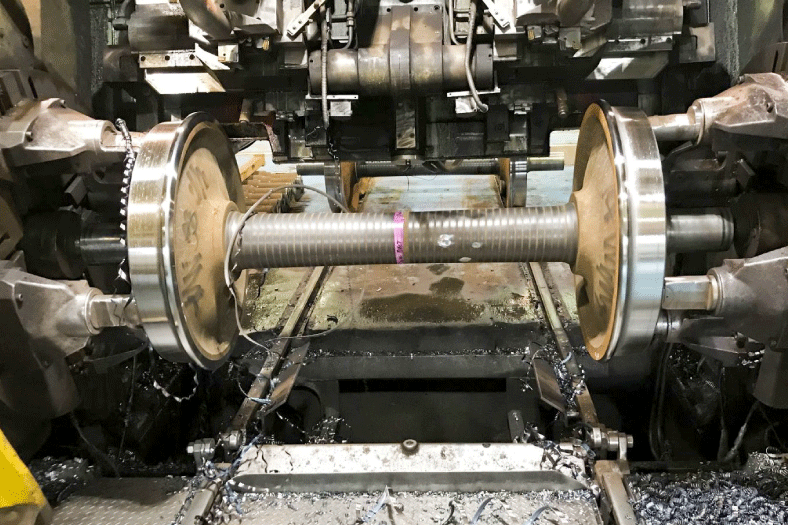

Wheel returning

Another example where Dormer Pramet provides support to the railway segment is in wheel returning. This too can see standard tools being modified to become custom-made specials, unique to the requirement of the application.

A customer in Philadelphia, USA, was having issues with its previous LNMT inserts as they were not able to break chips during a wheel turning operation. The resultant long, continuous swarf congested the area around the workpiece. The process to clear the chips is not only time consuming but can also be hazardous.

Dormer Pramet put forward its standard LNMT inserts, but during tests, found these too did not break the chips as required. Following further feedback and discussions with the customer, the company was able to make two key changes to its insert. First it added a corner radius chip breaker to relieve some of the pressure on the tool. It then tailored the geometry and design of the insert to prevent nesting at high depths of cut.

The end user wanted to make one pass, so the LNMT insert needed to be able to achieve a staggering .700” (18mm) depth of cut at the first attempt. Following the changes, the insert was put in for further testing. Not only did this new design fix the chip control problem, but it consistently outperformed all other inserts tested. The customer now orders its inserts from Dormer Pramet.

For more details on

Dormer Pramet’s railway assortment:

Visit: www.dormerpramet.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi