Machining process and measurement become intelligent and sustainable

January 11, 2019 3:52 pm

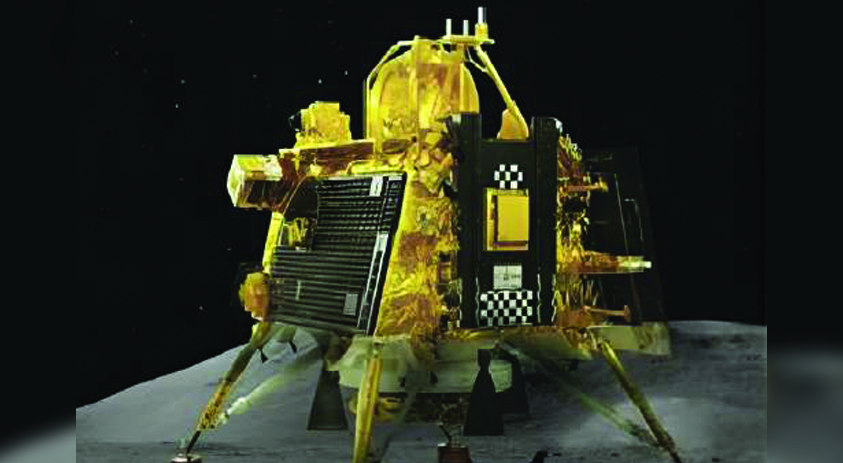

Intelligent machining processes are critical element in advanced manufacturing technology. Widely publicised trends such as Industry 4.0, the Industrial Internet of Things, cloud computing and data mobility provide manufacturers with an unparalleled opportunity to develop processes which deliver improved productivity and process capability. Automation, measurement and feedback can deliver process control throughout the stages of manufacturing. Optimised processes monitor not only the condition of parts, but also the performance of machines, process trends, interventions and environmental effects.

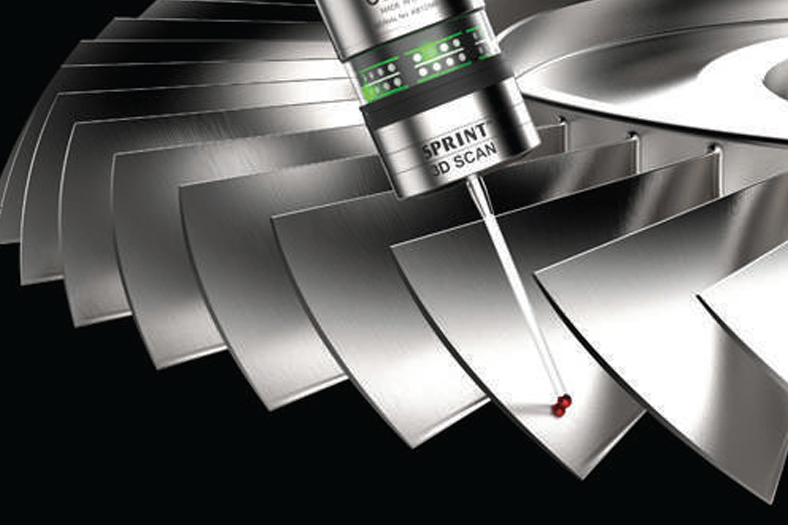

Renishaw provides technologies required to measure and control many of the key process variables in CNC machining and other forms of manufacturing. A combination of preventative, pro-active, reactive and tailgate measurements for process control has been used in Renishaw’s machining facilities very successfully over the past 25 years. This approach has enabled highly automated manufacturing with low overall labour costs to be realised.

Automation + accuracy + data capture + integration + intelligence = Productivity + capability

At IMTEX 2019, we are showcasing a Smart Factory set up, demonstrating to manufacturers how intelligent process control is key to the operation of a successful smart factory and to address the industry’s need for automated process control.

Inspection and quality control is still a parallel procedure

In today’s charged business atmosphere, the businesses across the sectors have taken a quickened pace and are looking forward for adapting the changes. The intelligent use of process control technologies within the manufacturing process has beneficial effects far beyond the traditional aspects of dimensional quality assurance and will be understood by the manufacturers. Those days are not far when inspection and control will be 100 per cent part of integral manufacturing.

A self-correcting manufacturing processes based on automated measurements

Manufacturing intelligence will emerge as a system of record, providing a wealth of data to drive more efficient production operations. Capturing data to the machine level and having that reside in a company-wide system of record will revolutionise the level of insights possible for troubleshooting production bottlenecks and quality problems. From the shop floor to the top floor, new insights gained using manufacturing intelligence will also change how OEE is perceived as a metric. Greater insights into just how a manufacturing site is performing and what steps can be taken to optimise its workflows will be known.

Process variation is the enemy of competitiveness and profitability. It causes waste and inefficiency, leads to high quality costs and manning levels, and results in late deliveries and poor traceability. The secret to consistent, automated, and productive machining is to understand where variation comes from and how to deal with it at source.

Renishaw provides a framework to identify and control variation in your factory, backed by innovative technology, proven methods and expert support. Renishaw can help bring your goal of ‘green button’ or ‘lights out’ machining into reach.

Authored article by:

Paul Weaver

Vice President – Sales & Marketing

Renishaw India

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi