Emerging flow measurement solutions for Air and Gas applications from Leomi Instruments

September 3, 2021 7:03 pm

Current market conditions demand superior and reliable products that are competitively priced. This implies industries to improve overall efficiency of equipment & plant processes and simultaneously conserve energy for achieving desired results. Flow measurement is becoming crucial for conserving energy for various utility measurements such as water, compressed air, natural gas etc. Flow measurement is also important for various other process gases for emission controls. With strict emission norms process efficiency needs to be tightly controlled where flow measurement is the ultimate requirement.

LEOMI An ISO-9001:2015 certified & Start-up India recognised company

Leomi aiming “Optimising Life” has identified various industrial applications helping in overall process optimisation and energy conservation by manufacturing high quality and reliable Thermal mass flow meters with technical collaboration with Softflow.de which has more than 20 years of proven experience in this field. Leomi has also installed India’s first fully automatic wind tunnel for In-house calibration of Insertion thermal mass flow-meter and various velocity-based instruments.

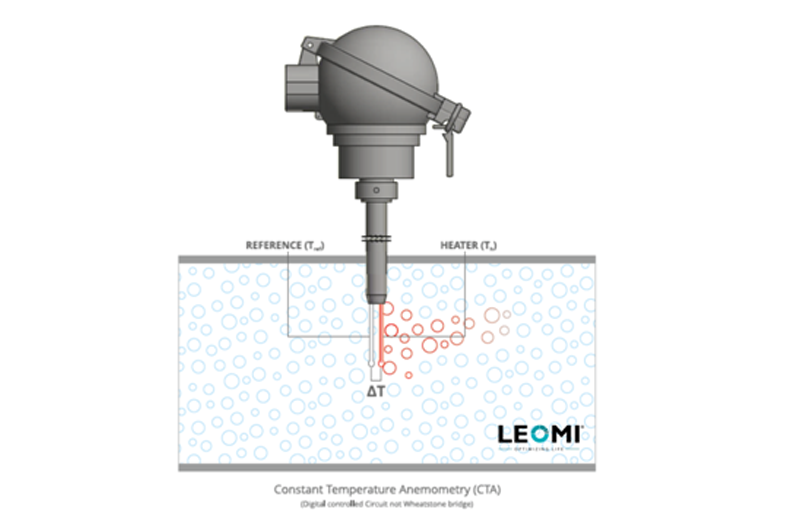

Leomi Insertion thermal mass flow meter design is based on Constant Temperature Anemometry combined with digital precise over temperature control. The physical principle of thermal dispersion from a heated element to the ambient medium (example: air or gases). This is affected by the velocity, density (temperature and pressure) and by the characteristic of the medium. The amount of needed energy is a function of the temperature difference ΔT and the mass flow.

Gas flowing through two RTD Pt-100 one reference (Tref) and another Heater (Th). The temperature difference (over temperature) Δt between the reference sensor (medium temperature) and the heater sensor is controlled constant. As per King’s Law, higher the mass flow rate, higher the cooling effect of the heater sensor, thus higher the power required to maintain the differential temperature constant. Therefore, the heater power is proportional to the gas mass flow rate.

Leomi Thermal mass flow meter offer benefits such as-

- No moving parts, robust metallic construction and direct mass flow measurement of gases.

- No pressure drops which saves energy against other conventional flow meters

- Highest turn down-ratio better than 100:1 provides high sensitivity helps in leak detection.

- High accuracy <±1.5 percent and resolution against conventional flow meters.

- Designed up to 400⁰C operating temperature and pressure up to 16bar or higher.

- Easily cleanable sensor & no significant effect of moisture like thin film sensor does.

- Can work in dirty or wet gas environments with accessories.

- Adjustable in various pipe sizes and versatile for different gas and mixtures.

- Digital controlled with No drift and long term mechanically stable design.

Applications where Leomi product innovations have been successfully used

- Compressed air flow, pressure, dew-point, power monitoring & logging for energy audits, which provides complete compressor’s data with overall efficiency and able to identify leakages and conserve energy.

- Flue gas & combustion air flow measurement for stack gas for emission controls having various features to suits power plant and industrial furnaces needs.

- Aeration basin air flow & dissolved oxygen control system in wastewater treatment plant.

- Natural gas overall utility monitoring solution in one instrument.

- Biogas flow measurement solutions for food and beverages.

- Chemical process gas emission by special HALAR® coated, PFA coated construction flow sensor for highly corrosive gases.

- Welding utility gas & medical gas flow monitoring and recording for consumption & cost control.

- Ventilation air control systems for critical power plants rooms and pharma clean rooms.

Leomi has also supplied Insertion thermal mass flow meter to various flue gas applications such as:

- Stack gas flow measurement in few of the India’s renowned coal based thermal power plant manufacturers

- Wet HCL stack gas flow measurement at renowned chemical manufacturers producing Hydrochloric 30 percent conc.

- HCl and SO2 (equimolar) with roughly 1 percent moisture gas flow process exhaust from fine chemical manufacturers.

LEOMI’s technical team is continuously working on research of other alternatives for various gas mass flow measurements solutions keeping in mind different industries’ process conditions.

Request to kindly write us your inquiry related to the above application and will happy to assist with flow solutions at our best.

For more information, log on to https://leomi.in/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi