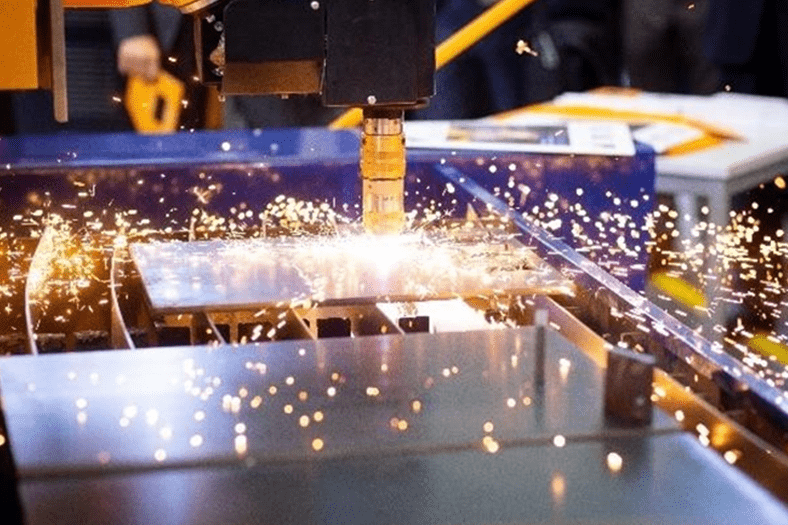

Digitally controlled plasma cutting system ‘Q’ ready for Industry 4.0

June 22, 2021 9:50 pm

For more than 60 years Kjellberg Finsterwalde has developed plasma cutting systems for a wide range of cutting tasks.

These high-quality products made in Germany make it possible to achieve excellent results for automated, mechanised or manual cutting. Since 2015, Kjellberg’s subsidiary Kjellberg Cutting and Welding India Pvt. Ltd. in Pune has taken care of all activities concerning the sales and service in India.

The latest products include the inverter power source Q which is based on a trendsetting concept: the cutting process is digitally controlled by means of the real-time communication of the components and is monitored on the basis of process and status parameters recorded via a number of sensors. The browser-based operator interface Q-Desk does not only display machine, process and consumption information but also derives forecasts and recommendations for action from such information. For example, maintenance dates can be determined and, thus, unnecessary downtimes avoided.

Moreover, the Q-Desk provides additional information for the user like FAQs or video tutorials that are independent of device and location.

On a wider scale, the process information can be provided to a larger machine network in order to ensure the interoperability with other systems like exhaust units or to prepare an extensive cost monitoring. By means of an integrated router, a direct connection can then be established with Kjellberg Finsterwalde’s customer service.

The industry 4.0-compatible machine series Q combines precise plasma cutting on an exceptional level with the demands on digitised production and was honoured for this with the “Award for Blechexpo“in 2019.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi