Redefining compactness of robotics

January 6, 2016 10:48 am

New KUKA KR CYTEC nano series stands for greater performance in the low payload category

KUKA introduces KR CYTEC nano series – the high-performance robots in the low payload category. In the 6 to 10 kgs payload range, the KR CYTEC nano series stands out primarily for its unprecedented compactness. These streamlined and agile jointedarm robots with a long reach replace the previous KUKA types KR 5, KR 62 and KR 5 arc, and set new standards in this category.

They have to be streamlined, agile and flexible and have a long reach in order to perform convincingly even in confined spaces. The increasing automation in general industry is resulting in robots finding their way into ever more branches of industry. In addition to robustness, precision and flexibility, improved energy efficiency, agility and accessibility in confined spaces are also becoming increasingly important. The new KR CYTEC nano series from KUKA has all of these characteristics. Outstanding performance, smooth and sensitive motion characteristics on the path and during positioning: that is what this new class promises in the low payload category.

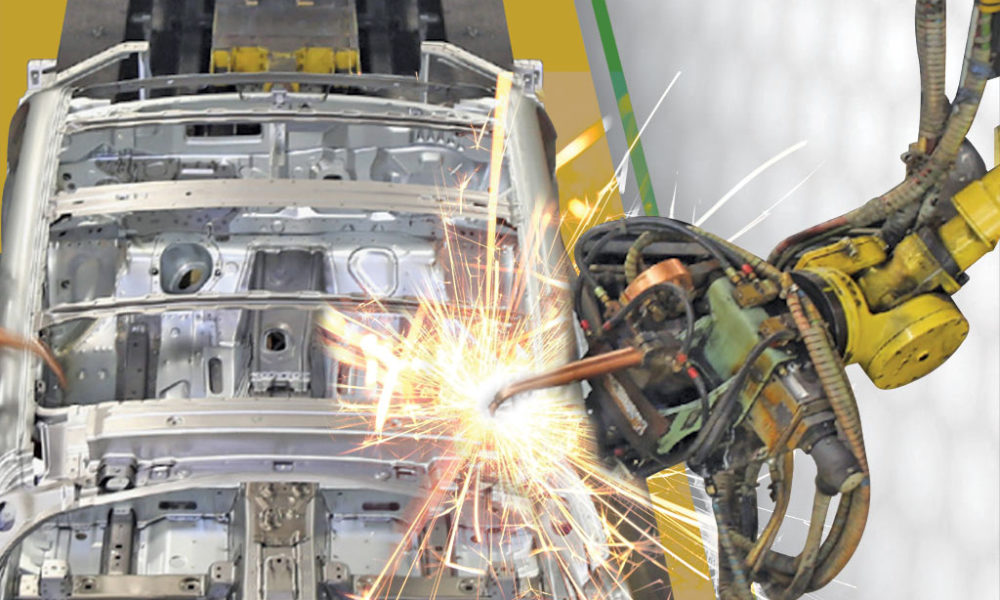

KR CYTEC nano consists of two product families – KR CYTEC nano for handling and assembly of small components and KR CYTEC ARC nano specialised in welding applications. Both families are available in different payload variants: the KR CYTEC nano with 6, 8 and 10 kg payload capacity with a reach of 1820, 1620 and 1420 mm respectively and the KR CYTEC ARC nano with 6 and 8 kg payload capacity with a reach of 1820 and 1620 or 1420 mm. “The most important thing for us was to significantly improve the robot’s compactness and performance,” explains Markus HollfelderAsam, Product Manager for the new KR CYTEC low payload class at KUKA Robotics. “It worked perfectly. The volume of the new KR 8 R1620 is 47 per cent less than that of its predecessor, the KR 62, despite the greater payload capacity and longer reach,” says HollfelderAsam. Thanks to the smaller footprint, it was possible to save space and material costs. “We have significantly reduced the disruptive contours of the robot, while the streamlined design of the wrist ensures utmost accessibility, even in confined workspaces.”

More compact, more robust, smaller footprint for handling, assembly and welding applicationsFor material handling applications, the KR CYTEC nano product family is also available in a High Protection (HP) variant. In this variant, the entire robot has a protection rating of IP65 and is thus perfectly protected against dust and waterjets; what is more, with a protection rating of IP67, the robot wrist can also withstand high surface temperatures, permanently large quantities of dust, lubricants and coolants. Even temporary submersion has no adverse effects.

Furthermore, the KR CYTEC ARC nano welding robot, with its streamlined hollowshaft wrist with bearings on one side and a diameter of 50 mm, allows positioning close to the workpiece. This configuration removes the risk for adverse effects on weld quality due to dangling dress packs. The infinitely rotating sixth axis means that no cycle time is lost turning the wrist back again, thereby boosting productivity. One feature that will particularly appeal to system partners and integrators in the welding sector is the generous free installation space on axis 3. This ensures optimal, space saving integration of the welding cabinet right next to the robot. Compared to other welding robots, this means a substantial reduction of the disruptive contours and significant space savings in the cell.

A large modular system to followWhile “nano” stands for the “small modular system,” and thus the smaller of the two new series, KR CYTEC will soon be introducing a “large modular system” providing convincing solutions for the next payload segment up to 22 kilograms. Here, once again, there will be two product families – the KR CYTEC for challenging handling and assembly tasks and the KR CYTEC ARC welding expert with a special hollow shaft. KUKA is thus closing a gap in the overall portfolio and offering the world’s largest range of models in this payload category with the greatest power density. With this change, KUKA’s new robot range will cover the demand for industrial robots in all conceivable customer requirements, from the agile specialist in the low payload category all the way up to the heavyweight champion that can lift over a metric tonne.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.