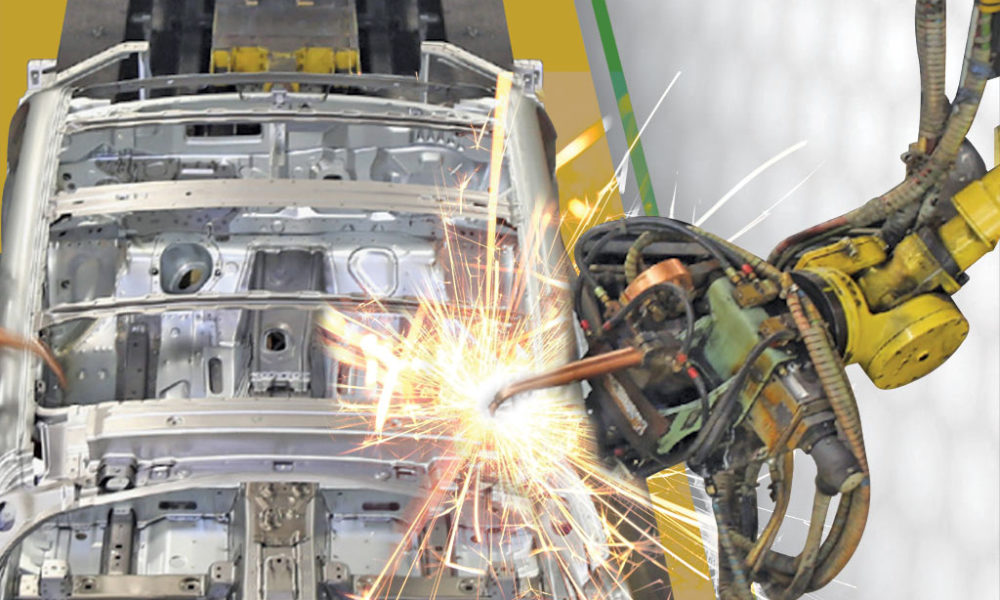

Changing phase of robotics in manufacturing sector

January 13, 2016 11:52 am

An overview of the current scenario of robotics in the Indian manufacturing sector and its adoption from international markets

The robotics industry has come a long way since its inception in India. Here, experts from the industry share their opinion on the present scenario of Indian manufacturing sector vis-à-vis international markets in terms of robotics adoption and also about the solutions their company offers in this field.

Current scenarioCurrently India has the population of almost 30,000 robots, the automotive sector which would be very good edge over comparatively as the FDI happening is more now.

Mitsubishi Electric India’s spokesperson says, “In F&B and pharma sector, robots should be widely used for non-productive area like pick and place and packing whereas we are lagging behind drastically in terms of meeting the production demand, even we have the cutting edge technology in this sector.”

The Indian SMEs are currently going through a struggle between productivity and investment i.e. with respect to the money invested in manpower and manual operations used for manufacturing goods the productivity is not satisfactory.

Navneet Chaudhary, Head – Sales, Marketing & Administration, SK Robotics LLP observes, “The manpower should be used for more intelligent works that is not possible to obtain or achieve with the help of a machine. The acceptance for such technologies and revolution is not positively accepted in India wherein in the international markets automation is viewed as cherry on cake.”

Potential growth areasTalking about the key potential growth areas for robotics in India, a spokesperson of Mitsubishi says, “For automotive, assembly, machine tending application, end of line testing are some of the potential growth areas and for electronics industry, expecting a good growth in this sector where robots are adopted especially for assembly, polishing and edge grinding for aesthetics (eg: Foxconn), in India would be major.”

Chaudhary believes, “The horizon should be broadened and hence the acceptance for new technologies should be taken into consideration. The hot iron to hit onto is all the manufacturing sectors.”

ChallengesSpeaking about the challenges that plague the industrial robotics in India, Mitsubishi’s spokesperson says, “The main challenge is cost, even today wages of manpower is less, so implementation is getting tough; but slowly the scenario is changing as there is high demand for quality product. Then awareness which is still considered to be ‘white elephant’ in India needs the basic education in all technical institutes. There is also lack of solution providers having complete knowledge to give the turnkey solutions.”Chaudhary too feels that cost is one of the main challenges, he says, “The productivity is not as much as the money invested in manpower and manual operations for manufacturing good.”

Mitsubishi’s solutionsMitsubishi Electric India is among the experts in the precise handling and assembly application with its servomotors, the range falls between 2kg to 20kg which is widely used in automotive precise assembly, electronics and semiconductor industry.

There are sales and service teams across India with application engineers at Bangalore, Pune and Delhi. Having both vertical and horizontal (SCARA) robot in its portfolio, Mitsubishi provides total solutions for most of the applications.

SK Robotics’ solutionsSpeaking on the organisation’s expertise in the field of robotics, Chaudhary says, “The expertise of our organisation is giving a complete turnkey solution where intelligent automation is required or needed from the customer’s end. Our USP that makes us an eccentric entity in the field of automation is to provide fail safe systems to our valuable customers along with intelligently programmed robots.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.