IoT transforming industries

June 11, 2018 4:33 pm

Palanisamy PL,

Director – Sales, Manufacturing and Services, Danfoss Drives

With emerging and advanced technologies like Internet of Things, 3-D Printing, Big Data and analytics, players are empowered to design, modify and create products and solutions that customers are looking for.

Future look for IIoT in manufacturing

According to a report by PwC titled – Industry 4.0: Building the Digital Enterprise, over 53 per cent of industrial companies are dependent on data analytics and 90 per cent of these companies expect data to play a significant role in their decision-making process.

Palanisamy PL, Director – Sales, Manufacturing and Services, Danfoss Drives, informs, “With emerging and advanced technologies like Internet of Things, 3-D Printing, Big Data and analytics, players are empowered to design, modify and create products and solutions that customers are looking for. Through these technologies, companies are now able to produce customer-centric solutions which should ideally be the main architecture of our design principles.”

Industries should also look at incorporating design thinking in their products to ensure we build them in such a manner that helps customers connect to various devices and gain maximum value from the products and solutions which shall help companies explore new revenue opportunities. However, it is important to keep in mind that digitisation can be disruptive. It is fundamental that companies ensure that the golden triangle of change is ready to make the transition i.e. people (who are at the crux), processes (which require human intervention) and technologies (that help perform processes).

With the advent of digitisation and smart manufacturing, by enhancing skillset and adopting ‘smart manufacturing’, the Indian manufacturing sector has the potential to grow six-fold by 2025 up to $ 1 trillion, creating up to 90 million jobs thus positioning India as one of the top three destinations by 2020.

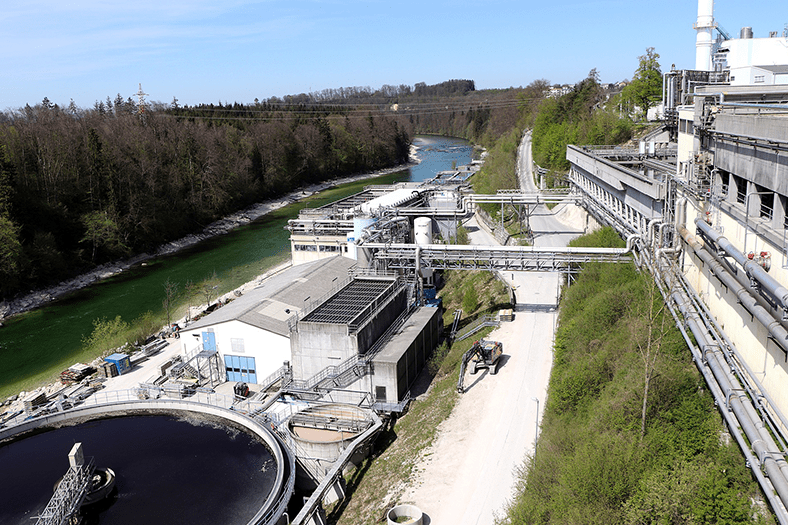

Danfoss’s preparedness in the area of IIoT

The IoT market has been growing as manufacturers of basically anything with an on-off switch look for ways to connect their devices to the Internet, increasing their functionality in ways never imagined. By predicting breakdowns, reducing waste, improving efficiency and more, the IoT is transforming nearly every sector of industry. In case off-highway mobile equipment, uptime is one of the most important factors. Services like geo-fencing, fleet management, calculating duty cycle and lifetime of components, performance, uptime, fuel usage and access to real time data can be provided using the data from machines. By having connected machines, OEM’s can schedule the maintenance of the machines before they breakdown thereby reducing the downtime of the machines. This also gives OEM’s opportunity to proactively connect with end users to provide service.

Across industries, increased productivity, minimised downtime and prevention of failures are common themes that are critical to increase the profitability of the process and manufacturing industries – all themes where IoT can bring new tools. Investment cycles in the process and manufacturing industries are long, and new trends tend to take time to develop. There are also clear security threats that must be dealt with if we are to move away from closed networks and automation systems into more open, and often more unsecure, global systems or connectivity.

Danfoss Drives is taking a practical approach to IoT starting from clear customer needs. Based on close co-operation with its customers, they have identified some initial stages that in themselves are not revolutionary, but are the first step towards the final phase of the IoT evolution, which is ‘autonomy’ of products. These initial stages already require development and design in new technology areas that have not traditionally been a focus of AC drive development. Palanisamy informs, “We believe that IoT will bring a difference to our industry as the capabilities of AC drives are now combined with enhancements in connectivity, data gathering and analysis. Today, we already have live deployments utilising the benefits of IoT where fault isolation and drive installation times have been significantly reduced after enabling remote management services.”

Full capitalisation of IoT means new ecosystems and partnering for companies like Danfoss Drives. Company’s deep expertise in AC drives and understanding of industry and application requirements are coupled with its customers’ insight into their own processes and machinery. In addition, the company also work towards a wide ecosystem of connectivity, security, computing and data storage players that bring their expertise to the overall solution.

In its power solutions business, Danfoss is bringing the IoT to mobile equipment. With data-gathering sensors, mobile networks, cloud-based computing services and analytics software, Danfoss is developing ways to predict maintenance needs in real time. In other words: if a pump is close to malfunction, the future IoT system will alert the operator before it happens, avoiding down time in the field.

In recent months, the company have noticed a strong trend of Danfoss OEMs toward real-time, IoT applications where its customers collect data from sources such as sensors, subsystems and components. In a series of feasibility tests with a working drum roller, an ADC demo vehicle, the group connected the machine remotely to a cloud computing platform via a web services communication tool (REST API). Danfoss Telematics Solutions (DTS) and Smart Analytics kits (PLUS+1 Controller with sensors) gathered data inside the drum roller in real time, transmitting it with a new DTS platform under development in order to test connectivity, data transfer, basic smart analytics and analysis capabilities.

This data can be aggregated, granulated and analysed to enable real-time analytics functions. Palanisamy informs, “Our new IoT Data Platform will enable us to both monitor data in near real-time, while calling up historical data from the database. Such real-time prediction requires three components: hardware and sensors in the machinery, analytics software and a user dashboard or app. Danfoss plans to upgrade its existing Telematics Solutions hardware to work with more data at a higher speed and with more flexible interfaces in order to make our analytics more accurate.”

In short – IoT offers plenty of new, interesting opportunities for the process and manufacturing industries. New innovations are inevitable as technical breakthroughs become more widely utilised in tomorrow’s products and services. The new era, however, will seize opportunities through concrete small steps that create immediate value for end users of products and processes – for which AC drives offer a perfect platform. As always, the revolution will become a commodity before we even notice that we are in the middle of a great change.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi