IIoT: The next wave of disruption in manufacturing

June 11, 2018 4:14 pm

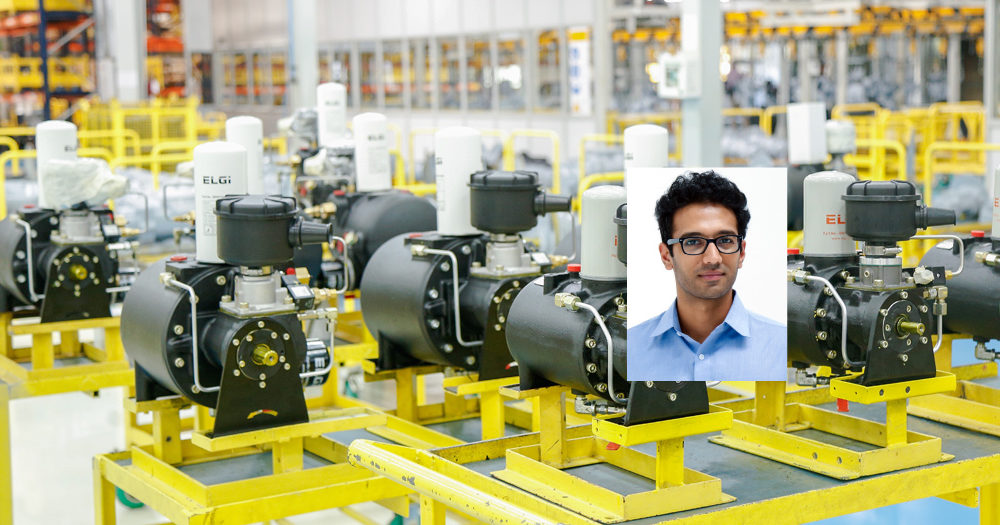

After witnessing the technological transformation at the Hannover Messe, Anvar Jay Varadaraj, Head – Marketing & Communications, Elgi Equipments Ltd explains how Artificial Intelligence, Big Data and automation are poised to change the manufacturing landscape.

This is the age of intelligence, and the manufacturing sector is seeing a major upheaval. Technologies such as Artificial Intelligence (AI), Machine Learning (ML) and industrial automation have already started to permeate and alter the course of every layer of the manufacturing industry, in what we call Industry 4.0, commonly referred as the fourth industrial revolution spearheaded by the infusion of data and computing power.

At the recently concluded Hannover Messe, the world’s leading trade show for industrial technology, ELGi Equipments could witness how AI is poised to change the manufacturing landscape which made them ponder about the implications of all these sweeping changes in the Indian context.

The first opportunity for Industry 4.0 and AI is in using Big Data to improve manufacturing processes. How technology converges to make processes more efficient by the day, reduce errors and get to perform with amazing precision with least human intervention was interesting. At the Hannover Messe, Microsoft demonstrated their software built for autonomous material-handling drones that have been tested in Toyota’s manufacturing floors. Buzzing non-stop, these drones, fit with cameras, radar and a bunch of sensors operate just as humans would, but with least errors and utmost precision. They even render quality managers redundant!

Augmented Reality (AR) is another application that could greatly transform manufacturing. How AR lenses helped assembly-line workers pick parts faster and better with no errors was displayed at the Hannover Messe. Such intelligent applications may make it all seem like they are built to cut human expertise from the picture, but in turn, make human eye indispensable and inevitable, as the algorithms definitely need to make sense of them – to figure out the big picture.

Another great opportunity for AI and Big Data in manufacturing is how they can transform customer service. Microsoft showcased a fleet management system that it developed hand-in-hand with a logistics major. This system has made identifying anomalies, scheduling services and cutting downtime costs a breeze. IBM displayed how they have helped an elevator company develop a system that constantly monitors elevators and reports key data such as speed, energy and downtime to a central dashboard to help better customer experience.

It is human tendency to overestimate the impact of technology in the short term, and underestimate it in the long term. Data and reporting systems have benefited us in terms of business metrics at varying levels. While the Microsoft powered drones in the shop floor lowers human costs, cuts errors and increases safety, the IBM elevator monitoring system may not give us any tangible result, and only makes the whole system run better. In the Indian context, studying the impact of these technologies in how they affect the human capital, which is abundant, is important and crucial to understand how we can implement them.

Thus, what attracted the most is how emergent technologies affect the human condition in the industry. Any company that seeks to implement new technology should be sensitive to the experiences and abilities of the human operators, and at the same time, develop strong people strategies to accommodate them in the short term, and also in the long haul. This in turn calls for a thorough curriculum change in how blue-collar workforce is trained. Basics of AI and ML should become part of vocational and skill development plans. In the long run, public and private sectors should join hands to pick technology skills that today’s data-centric manufacturing processes need, such as in data analytics and security.

In the context of white collared workers, technology may render existing functions such as quality management and data analytics redundant in the future. People offset by such upheavals should in turn prepare to reskill themselves in areas that demand the human eye and judgement, such as in information and data security.

Without a doubt, it is abundantly clear that AI, Big Data and automation are all set to rattle every step of the manufacturing chain, and we may be underestimating the onslaught. While such changes would give economic benefits and high-quality products, they give rise to serious questions about what we have to do with our human resources. Only sustained, well thought reskilling measures can prepare workers towards becoming what we can call Workforce 4.0, which fits the demands of Industry 4.0. Strong grassroots vocational and skilling programs such as those delivered now in Germany are crucial to introduce our workers to the bold new future – where cognition and analytical thinking are more essential than just desirable.

ELGI has always thought about what it could do with emergent technologies to delight customers. The company has constantly endeavoured to infuse intelligence in our manufacturing processes to cut costs and improve efficiency. Since manufacturing lines are run on high human input and low automation, any efficiency improvement comes at a huge cost. However, ELGI has indeed identified avenues for data gathering at each step to help reduce inventory at every level. This initiative has helped machine operators with intelligence, empowering them to take better decisions at every level.

ELGi’s Air Alert system is a novel IoT application, which has a SIM card slot in its compressor controllers. The SIM card transmits vital data such as temperature, pressure and energy consumption to the owner or manager who can proactively monitor and control any single or multi-installations of air compressors to save energy and avoid downtimes by checking on anomalies. The data also helps improve ELGi’s service call scheduling, and empowers service engineers to focus on critical issues by freeing up their time. Long term analysis of such data also helps ELGi design its compressors better.

Technology always has two dimensions, the ‘know-how’, and the ‘know why’. Having systematically invested in manufacturing technology since 1994, ELGi has always focused on the ‘know why’ and continuously upgraded its technology.

ELGi also bundles the Air Audit programme to its line of air compressors in addition to its standard Air Alert IoT system. ELGi’s Air Audit programme is a review of how any operation uses its compressed air. A pilot project run for the Indian Texpreneurs Federation (ITF) has helped reduce its compressed air cost by up to 43 per cent. ELGI has been significantly ramping up its R&D, with its ELGi Innovation Programme. About 3 per cent of the company’s revenue is pooled into R&D. With such an impetus, the company is now gearing up to introduce IIoT as a standard very soon, in the coming months – with a motive of reducing downtime and increase efficiencies. As they say, the best is yet to come.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi