A remarkable feat that cements India’s position in the global space exploration arena, India has invested about $75 million in its Chandrayaan-3 mission. With the vision of a successful mission, the nation aims to become the fourth country to achieve a successful spacecraft landing on the moon’s surface.

“Chandrayaan-3 scripts a new chapter in India’s space odyssey. It soars high, elevating the dreams and ambitions of every Indian. This momentous achievement is a testament to our scientists’ relentless dedication. I salute their spirit and ingenuity,” Prime Minister Narendra Modi said.

In a momentous leap towards lunar exploration, the Indian Space Research Organisation (ISRO) embarked on its much-anticipated Chandrayaan-3 mission. Following the setbacks of its predecessor, Chandrayaan-2, ISRO launched the third lunar exploration endeavour on July 14, 2023, at 2:35 pm IST, with a determination to overcome past challenges. This ambitious mission aims to deploy a lander and the Pragyan rover to the lunar surface, significantly advancing India’s space exploration endeavours. While the stakes are high, hopes are riding on a successful landing near the lunar south pole region, anticipated to occur on August 23, 2023.

India’s historic Chandrayaan-3 launch from Sriharikota puts the nation in an esteemed league, becoming the fourth country to achieve a successful spacecraft landing on the moon’s surface.

Lunar Advancements -3

Chandrayaan-1, the first mission in the series, made a groundbreaking discovery of water on the lunar surface, earning praise from premier space agencies like NASA. Chandrayaan-3 aims to take things to the next level with its robust Lander using ISRO’s Launch Vehicle Mark-3. There is tremendous excitement across the country for Chandrayaan-3, especially since Chandrayaan-2 faced challenges just minutes after its September 6, 2019 descent.

The previous missions, Chandrayaan-1 and Chandrayaan-2, have been groundbreaking in their own right. Chandrayaan-1 confirmed the presence of water molecules on the Moon, altering our perception of the celestial body from being bone-dry and uninhabitable to a dynamic and geologically active entity. Meanwhile, Chandrayaan-2’s Orbiter detected crucial elements like chromium, manganese, and sodium for the first time through remote sensing, revolutionising our understanding of the Moon’s magmatic evolution.

With the promising strides in space exploration and innovation, Chandrayaan-3 holds high hopes for furthering our understanding of the Moon’s mysteries. Equipped with advanced payloads, including Chandra’s Surface Thermophysical Experiment (ChaSTE) and the Instrument for Lunar Seismic Activity (ILSA), this mission aims to unravel the Moon’s secrets and pave the way for future lunar expeditions.

After a series of orbit-raising manoeuvres, Chandrayaan-3 will be inserted into the Lunar Transfer Trajectory, covering a staggering distance of over 300,000 km to reach the Moon in the next few weeks after its launch. The spacecraft will be equipped with cutting-edge scientific instruments to study the Moon’s surface. The mission has undergone rigorous ground tests and simulations, making necessary modifications to ensure the success of the Lander. Chandrayaan-3’s Lander and Rover modules are equipped with payloads that will provide valuable data on lunar soil and rocks, including their chemical and elemental composition, contributing to the scientific community’s knowledge. The rover, equipped with six wheels, is expected to work on the Moon for 14 days, capturing valuable images with multiple cameras, added Dr Jitendra Singh, Minister of State for the Ministry of Science and Technology and Prime Minister’s Office.

Chandrayaan-3 aims to spearhead new frontiers in interplanetary missions through its innovative Lander module (LM), Propulsion module (PM), and Rover. With the LM’s ability to softly touch down on a designated lunar site and deploy the Rover, cutting-edge in-situ chemical analysis of the lunar surface will be carried out during its mobility. The Lander and Rover are equipped with scientific payloads, paving the way for experiments on the Moon’s surface. The PM’s crucial role is to ferry the LM from launch vehicle injection to a final lunar orbit of 100 km in a circular polar trajectory, after which it will part ways. The Propulsion Module will also operate a scientific payload post-separation from the Lander Module.

Utilising the GSLV-Mk3 launcher, Chandrayaan-3 is destined for an Elliptic Parking Orbit (EPO) of approximately 170 x 36,500 km. The mission’s core objectives include:

- Showcasing a safe and gentle lunar landing.

- Demonstrating Rover mobility on the moon.

- Conducting groundbreaking in-situ scientific experiments.

India has since spent about $75 million on its Chandrayaan-3 mission.

Indigenous Manufacturing

Chandrayaan-3 boasts an impressive lineup of companies collaborating to make this interplanetary dream a reality. Leading the charge are renowned names like Larsen and Toubro (L&T), Hindustan Aeronautics, Bharat Heavy Electricals, Paras Defence and Space Technologies, Godrej Aerospace, Walchandnagar Industries, Centum Electronics, and MTAR Technologies.

Godrej Aerospace has played a pivotal role in the Chandrayaan-1 and Chandrayaan-2 missions. During Chandrayaan-1, the company contributed the Vikas engine, thrusters, and critical parts for antennas used in remote sensing and ground systems. For Chandrayaan-2, Godrej Aerospace provided the L110 engine and CE20 engine for the GSLV Mk III launcher, along with thrusters for the Orbiter and Lander and components for the DSN antenna.

The company has manufactured the L110 engine for the core stage and the CE20 engine thrust chamber for the upper stage of the Chandrayaan-3. In addition to this, Godrej Aerospace has also provided essential thrusters for the spacecraft. Firmly committed to indigenous manufacturing and technological progress, Godrej Aerospace has ambitious plans. The company is set to invest ₹250 crore in a state-of-the-art facility in Maharashtra’s Khalapur, which will house advanced manufacturing, assembly, and integration capabilities. Maneck Behramkamdin, AVP & Business Head, Godrej Aerospace, said, “We take immense pride in our contribution to ISRO’s Chandrayaan 3 mission, which exemplifies our commitment to nation-building and self-reliance. At Godrej Aerospace, we remain committed to indigenous manufacturing and technological advancements, contributing to driving the nation’s progress in space projects and civil aviation.

Larsen and Toubro was a pivotal contributor to Chandrayaan-3 mission in supplying various crucial components. They supplied ground and flight umbilical plates to critical booster segments in a strict timeframe. L&T’s significant involvement also extended to the system integration of the Launch Vehicle.

The Prime Minister’s opening up of the space sector to private players has created a collaborative ecosystem, facilitating the pooling of assets, resources, and expertise. The Chandrayaan-3 mission owes a significant part of its accomplishments to the contributions made by the private industry. As Chandrayaan-3 embarks on its lunar journey in a precise orbit, ISRO confirms the spacecraft’s health to be in optimal condition. This landmark mission is a testament to the power of collaboration, showcasing India’s determination to advance in space exploration with indigenous manufacturing.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

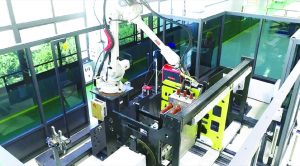

Automation and Industry 4.0 advancements are transforming industries through smart and dark factories. This article explores their potential and implementation strategies for success.

Automation is crucial in achieving operational excellence across various sectors by simplifying procedures, enhancing resource management, and providing outstanding goods and services. Despite encountering some obstacles, the advantages of automation far surpass them. Enterprises that embrace automation set themselves up for enduring success in a competitive environment. Intelligent factories, driven by Industry 4.0 advancements such as the Internet of Things (IoT), Artificial Intelligence (AI), and data analysis, present unparalleled possibilities for improving efficiency, productivity and fostering innovation.

The Dark Factory

Dark factories, also known as lights-out factories, are completely automated facilities that operate without human workers and even function in darkness. In a dark factory, sophisticated automation technologies independently take charge of the entire production process, from assembly to maintenance. However, dark factories encounter challenges such as substantial initial investment requirements, continuous maintenance expenses, and ethical considerations regarding the displacement of human jobs.

As automation and Industry 4.0 progress, dark factories are gaining traction, and many businesses are actively exploring their potential.

· FANUC Dark Factory: FANUC leads in lights-out factories, as it has implemented dark factories, employing advanced robotics and AI to achieve efficient 24/7 production without human involvement.

· Adidas introduced SPEEDFACTORY, an innovative concept for producing customised sneakers on demand. While the initial SPEEDFACTORY ceased operations in 2019, Adidas continues to explore automation and smart factory approaches in its manufacturing processes.

· IBM conducted trials of lights-out manufacturing in New York, automating operations and reducing human intervention during non-operational hours to evaluate the viability and advantages of this approach.

· Geely’s Dark Factory, spread across a vast 2,260-acre area, utilises advanced equipment and processes, including robots, stamping, and welding workshops, to optimise its manufacturing operations.

Dark factories present an alluring vision of the future, but their applicability depends on the industry. Striking a balance between efficiency and addressing social and ethical considerations is paramount as we delve into their possibilities in the forthcoming years.

The 7-Step pathway to implementation

1. Lay the Groundwork: Commence the smart factory journey by evaluating and modernising your infrastructure. Clearly define objectives and create a well-structured plan for successful implementation.

2. Embrace the Internet of Things (IoT): Incorporate IoT sensors for real-time data collection, enabling efficient monitoring and analysis within smart factories. Seamless integration ensures smooth data exchange and well-informed decision-making.

Example: Bosch’s Successful Implementation of IoT has effectively integrated IoT into its manufacturing facilities. This has helped them gain real-time insights into machine performance, quality metrics, and energy consumption. It has also resulted in significant enhancements in production efficiency and maintenance.

3. Embrace Artificial Intelligence (AI) and Machine Learning (ML): Utilise AI to optimise real-time processes. At the same time, ML analyses historical data to identify potential machine failures and enable predictive maintenance, thereby reducing unplanned downtime.

Example: Siemens’ AI-Driven Predictive Maintenance employs AI and ML algorithms to predict equipment failures, facilitating optimal maintenance scheduling and reducing operational disruptions and costs in their smart factories.

4. Integrate Big Data Analytics: Collect, secure, and visualise data from IoT devices, production, and supply chain. Leverage big data analytics to gain predictive insights in the smart factory.

Example: General Electric’s “Brilliant Manufacturing” employs big data analytics on machine and process data to optimise production, minimise downtime, and identify opportunities.

5. Ensure Cybersecurity and Data Protection: Implement cybersecurity measures such as firewalls, encryption, and access controls. Foster a culture of security consciousness to safeguard the smart factory.

Example: Schneider Electric’s Cybersecurity Solutions ensures smart factory cybersecurity through encryption, access management, and continuous monitoring to protect connected systems and data.

6. Embrace Robotics and Automation: Enhance productivity by deploying cobots to assist with repetitive tasks. Embrace flexible automation to achieve agile manufacturing and adapt to changing requirements.

Example: BMW’s Smart Production Line utilises collaborative robots (cobots) to aid workers in assembling complex components. This enhances efficiency and ergonomics in the manufacturing process.

7. Implement Augmented Reality (AR) and Virtual Reality (VR): Employ immersive AR and VR for onboarding and upskilling, reducing training time. Provide maintenance personnel real-time information during equipment repairs and troubleshooting using AR and VR.

Example: Airbus’ Augmented Reality Assembly uses AR technology with headsets to streamline assembly processes, improving accuracy and efficiency.

Embracing the path to becoming a smart factory requires thorough planning and effective leadership. Gaining insights from real-world instances and adopting best practices is crucial for achieving sustainable growth in the era of digitalisation

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

AMT’s products stand at the forefront of technological advancements, promising to elevate productivity levels, enhance accuracy, and deliver exceptional results in machining operations. With AMT’s cutting edge solutions, businesses can experience the transformative impact of advanced machining technology firsthand.

Ahire Machine Tools Pvt. Ltd. has established itself as a prominent player in work-holding and tool-holding solutions, focusing on enhancing productivity through innovative approaches. The company is dedicated to achieving maximum efficiency, specializing in advanced solutions for work holding, mainly for three- and five-axis machines.

Their work-holding products are crucial in securing workpieces during machining, ensuring precision and accuracy. The company primarily focuses on developing comprehensive work-holding solutions tailored to the Indian market. These solutions ensure optimal clamping, even in the smallest portions of the component, resulting in enhanced precision and improved productivity.

Ahire Machine Tools is committed to delivering products known for their precision, performance, and reliability. They offer a range of cutting-edge drill and tapping machines, carefully engineered to meet the diverse needs of various industries, including manufacturing and automotive.

The drill machines are designed for exceptional performance and efficiency in hole drilling, reaming, and countersinking. With their robust construction and advanced features, the drill machines enable users to achieve remarkable results while minimising downtime.

Similarly, the tapping machines have advanced control systems and high-quality components, providing precise and consistent tapping operations for internal and external holes, ultimately enhancing productivity and accuracy. Incorporating tapping machines into manufacturing processes enhances productivity and accuracy significantly.

The drill and tapping machines offered by Ahire Machine Tools represent the cutting-edge future of machining. Their products lead the way in technological advancements, allowing customers to enhance productivity levels and accuracy and achieve outstanding results in machining operations.

Apart from their wide range of products, Ahire Machine Tools is dedicated to providing comprehensive after-sales support and service to maximise the value their machines bring to customers. A team of skilled technicians is available to assist with installation, maintenance, and troubleshooting, ensuring uninterrupted productivity for businesses.

As a forward-thinking company, Ahire Machine Tools continues to invest in research and development, constantly exploring new technologies and methodologies to improve the performance and efficiency of their machines.

In conclusion, Ahire Machine Tools Pvt. Ltd. offers top-notch workholding and tool-holding solutions that significantly enhance productivity and precision in machining operations. Their range of drill and tapping machines represents the future of machining, providing businesses with improved efficiency and exceptional results. Partnering with Ahire Machine Tools promises a difference in performance and productivity through their innovative solutions.

For more information, visit:

www.amtplindia.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Introducing MAGNET-SCHULTZ: Powerful holding and permanent electromagnets for optimal holding force.

MAGNET – SCHULTZ presents their cutting-edge holding and permanent electromagnets in the quest for a simple and effective solution to fix or transport magnetic workpieces. Engineered to deliver remarkable holding forces with incredibly short strokes, these electromagnets offer a versatile and reliable approach to various applications.

Whether keeping doors or flaps open or closed or requiring a swift yet robust hold, MAGNET-SCHULTZ’s electromagnets have covered you. The possibilities are vast, with options for holding solenoids and permanent holding magnets featuring bare or galvanised pole surfaces and complemented by appropriate armatures.

MAGNET-SCHULTZ’s permanent holding magnet GMP operates on a closed circuit principle, utilising an integrated permanent magnet to attract ferromagnetic counterparts consistently. When a supply voltage is applied with the correct polarity, an integrated coil balances the magnetic field, allowing for a controlled release of the fixed counterpart. With applications in mechanical engineering, fixture construction, conveyor technology, and door-holding systems, MAGNET-SCHULTZ’s solutions offer interlocking capabilities and high-holding force electromagnets to elevate your projects to new levels.

Sizes (Ø): 25 mm, 30 mm, 35 mm, 50 mm

Holding force: 110 N – 800 N

- Increasing magnetic force vs. stroke characteristic

- Electrical connection via free flexible lead ends

- Fastening via tapped holes on the rear side

- Protection class: IP00

- Voltage type: direct current, DC

- Galvanised pole surface.

Sizes (Ø): 25 mm, 30 mm, 35 mm, 50 mm

Holding force: 110 N – 800 N - Increasing magnetic force vs. stroke characteristic

- Electrical connection via free flexible lead ends

- Fastening via tapped holes on the rear side

- Protection class: IP00

- Voltage type: direct current, DC

- Galvanised pole surface

For more details, contact: Magnets India Chennai – 600 028 Ph. 9840091969, 044- 42833346

email : info@magnetsindia.net

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The MX-System has earned top accolades, is recognised in the highest category by the Red Dot Award, and is honoured with the iF Design Award.

Beckhoff presents the MX-System, a groundbreaking automation solution that has the potential to revolutionise the automation industry by eliminating conventional control cabinets. This innovative system has garnered prestigious awards, including the “Best of the Best” Red Dot Award and the iF Design Award, acknowledging its cutting-edge product design.

The MX-System is a modular and space-efficient automation system comprising an aluminium baseplate and plug-and-play function modules. Notably, this assembly is waterproof and dustproof, allowing direct mounting on machines without additional protective housing. The system’s versatility extends to its ability to integrate into various machines, both functionally and aesthetically, seamlessly. Beckhoff collaborated closely with the Adrian and Greiser design agency to achieve this, resulting in a visually appealing and ergonomic design that highlights the system’s unique capabilities. The MX-System’s compactness and continuity are evident, making installation and assembly remarkably simple, while each component retains its distinct character.

This innovative design concept also won over the Red Dot jury of around 50 international product design experts. Every year, this award honours industrially manufactured products with outstanding design quality: the products must be aesthetically pleasing, functional, smart, or innovative. The MX- System offers so many special features and benefits here that it was honoured with the Red Dot: Best of the Best Award for groundbreaking design, the highest award in the competition. According to the jury, only the best products in a category receive this award. Another renowned jury, consisting of 132 design experts from 20 countries, is equally convinced. They awarded the MX system the iF Design Award 2023.

For more information, visit: www.beckhoff.com/mx-system

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

In the world of machinery and equipment, regular servicing and using high-quality lubricants are paramount for achieving peak performance. These essential practices safeguard machines by minimising friction, dissipating heat, and protecting against wear and tear. This report delves into the critical role that quality lubricants play in ensuring the efficient functioning of various mechanical systems.

India’s machine tools segment is witnessing promising growth. Its market size is estimated at USD 100.63 billion in 2023, and is expected to reach USD 116.19 billion by 2028, growing at a CAGR of 2.92 percent during the forecast period (2023-2028). With promising growth, the machine tool segment in India encompasses a wide range of equipment, thereby necessitating use of superior lubrication solutions, timely servicing and upkeep for unhindered operations.

Despite its potential, the machine tools segment encounters some challenges in adoption of technology. The increasing complexity of equipment too demands skilled operators who can effectively operate and maintain these advanced tools. Workshop operators encounter their own set of challenges, including inadequate maintenance practices, inefficient lubricant management, and suboptimal machine health. These factors contribute to reduced performance, increased downtime, and higher maintenance costs. Overcoming these challenges requires comprehensive solutions that address the specific needs of operators.

Maintaining machines through regular servicing and proper lubrication is vital for optimal performance. Quality lubricants play an imperative role in preserving machine health by reducing friction, dissipating heat, preventing wear and tear, and ensuring efficient functioning. To address such issues, Mobil™ has developed MachineXT, a ground-breaking initiative that revolutionises lubricant management services and transforms the machine tool segment.

High-performance cleaner lubricants for extended productivity

Based on a comprehensive understanding of the challenges faced by the machine tool segment, Mobil has developed MachineXT– a remarkable transformation in managing equipment performance with state-of-the-art mobile filtration services. MachineXT offers tailor-made solutions that will unlock unparalleled productivity and efficiency, furthering industrial excellence.

The oil filtration system machine in MachineXT, which has used cutting-edge technology with advanced three-stage solid filtration systems, can remove fine solid particles and moisture from lubricants, ensuring cleanliness, and minimising the risk of machine damage. It can clean various types of lubricants such as hydraulic oil, gear oil, engine oil, turbine oil, and circulating oil.

The viscosity range (32 cst to 320 cst) includes a wide array of lubricants which are both mineral-based and synthetic. This machine is equipped with a sensor that can assess the cleanliness level of oil before and after the filtration process, adhering to ISO 4406 standards This sensor allows for accurate monitoring and evaluation of oil cleanliness, ensuring that the filtration process effectively removes contaminants. Specifically, it excels in filtering hydraulic oils, achieving ISO code 17/15/12 with ease.

MachineXT’s low vacuum dehydration system is a high-end tech machine that is widely recognised and utilised for the dehydration (moisture removal) of lubricants. This advanced technique effectively eliminates moisture from oil, which can exist in dissolved, emulsified, and free forms. The dehydration system employs a vacuum chamber and a shower arrangement for the oil, which may contain moisture. The system also includes a heater arrangement that heats the oil to a controlled maximum temperature of 60°C. Once heated, the oil is showered inside the vacuum chamber, which is maintained at a controlled vacuum level of 750 torr. Under these vacuumed conditions, the moisture particles in the oil undergo evaporation or vaporisation, effectively separating them from the oil. The moisture is then removed from the chamber. Meanwhile, the clean, moisturefree oil collects at the bottom of the chamber and is then delivered into the system using a delivery power mechanism, ensuring that the purified oil is readily available for lubrication purposes.

The coolant sump cleaner is another highly efficient solution equipped with a powerful two-stage vacuum blower. Its vacuum technology creates a strong suction force that effectively draws in coolant, metal chips, swarfs, and other contaminants from the coolant tank, passing them through a stainless-steel mesh basket. This versatile cleaner finds applications in CNC/VMC machines, effectively cleaning various types of coolants such as soluble cutting oil, neat cutting oil, water emulsion, quenching oil, and even storage tanks. With no filter element and no replacement costs, the coolant sump cleaner offers an improved product finish, reduced coolant consumption with an extended coolant changing periods and reduced machine downtime.

The tramp oil separator removes contaminants and tramp oil from coolants used in CNC machines. With its built-in air-operated diaphragm pump, it effectively sucks the contaminated coolant from the CNC machine’s sump and directs it through a stainlesssteel strainer to remove larger particles. As the coolant flows further, it passes through a molded honeycomb device that uses surface tension to separate the tramp oil from the coolant. The collected tramp oil is collected in a dedicated tray, while the clean coolant is returned to the CNC machine’s sump.

MachineXT also offers tank set additives such as biocides, defoamers, pH boosters, and alkaline water-soluble cleansers for metal-working coolant management.

On-Site Servicing Solutions

MachineXT also provides the MobilServSM Lubricant Analysis (MSLA) and MobilServSM Grease Analysis (MSGA) suite of comprehensive services that assesses lubricant conditions, contamination levels, and potential issues. MSLA can save as much as 66 percent of sampling time while providing the lubricant oil analysis needed to keep the equipment productive and minimise costly repairs.* MSGA can offer additional insights that will enhance equipment life. It can conduct six tests from one gram of grease sample. This convenient exercise enables problem identification before occurrence, minimising unscheduled downtime to improve productivity throughout. The testing services include lubricant viscosity testing, pH testing, patch test, water crackle test, chloride test and refractometers. These services provide essential insights into key parameters, ensuring equipment performance and durability.

Through these on-site testing services, MachineXT empowers businesses to monitor and optimise their lubricants and coolants effectively.

MachineXT is set to transform India’s machine tool segment. By addressing the challenges faced by the sector and workshop operators, it offers a game-changing solution for enhanced productivity, efficiency, and machine health. Through its state-ofthe-art technology and tailored offerings, it empowers workshop operators to unlock unparalleled performance, reduce maintenance efforts, and optimise the lifespan of their machines.

*This performance is based on the experience of a single customer. Actual results may vary.

For more information, please visit https://www.mobil.co.in/en-in/business

(Exxon Mobil Corporation has numerous affiliates, many with names that include ExxonMobil, Exxon, Esso and Mobil. For convenience and simplicity, those terms and references to “corporation”, “company”, “ExxonMobil”, “EM”, and other similar terms are used for convenience and may refer to one or more specific affiliates or affiliate groups.)

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

PortaCount Respirator Fit Tester from TSI, with over 35 years of innovation, sets new standards in terms of reliability, accuracy and ease of use.

From its inception in 1987 with the introduction of the original PortaCount® Respirator Fit Tester, TSI has exemplified unwavering dedication to innovation. Taking great care to heed valuable feedback and embrace emerging knowledge, TSI strives to develop the most exceptional respirator fitting test solutions. Throughout the successive evolutions of the PortaCount® Fit Testers, TSI has consistently surpassed previous benchmarks regarding reliability, precision, and user-friendliness. Their commitment to excellence in meeting industry standards remains steadfast, extending far beyond the current fourth-generation systems. At TSI, the philosophy towards industry standards is simple yet profound: Raise them.

Intelligent Fit Test solutions: ‘The Proven Fit Tester’

PortaCount® Respirator Fit Testers combine real-time and real-world measurements to advance respirator safety beyond the capabilities of any other fit tester. They play a vital role in your respiratory protection program, supporting the entire fit test process from training and mask selection to compliance reporting.

By utilising the most efficient and rapid quantitative fit testing method available, PortaCount Fit Testers ensure safety by identifying poorly fitting masks accurately. In less than 2½ minutes, they deliver a consistent and objective OSHA-compliant respirator fit test. These fit testers offer industry-first features that educate staff on how to wear respirators for maximum protection. Moreover, they go beyond the fit test, enabling users to observe how a respirator’s fit changes in real-time during donning and adjustment, providing valuable training and simplifying mask selection.

Measure safety in action

The PortaCount® Respirator Fit Testing equipment evaluates respirator fit while the user engages in dynamic activities such as moving, breathing, and talking, replicating real-life movements in work conditions. The instrument provides clear instructions, guiding users through the fit test process. Once the fit test is finished, generating reports becomes a straightforward task.

The PortaCount Respirator Fit Tester Model 8048 provides a consistent and objective testing experience across all respirator types, including all N95 filtering facepieces. FitCheck® Mode shows in real-time how respirator fit changes throughout donning and adjustment, helping users select the suitable mask and identify the best fit more quickly. Video animations guide staff through proper fit test exercise movements during a fit test, providing a consistent testing experience and freeing fit test administrators to multitask. Group fit testing allows administrators to test up to four personnel with four PortaCounts simultaneously.

TSI suggests opting for the industry’s most dependable, efficient, and user-friendly fit tester to enhance staff’s safety. With advanced software and features, this fit tester improves the efficiency and productivity of the respiratory protection program, covering everything from training to compliance reporting. It is trusted by professionals globally.

Best service in the business: Just like its instruments

The true measure of a company’s strength lies in the post-sale phase and is reflected in the level of support. PortaCount Respirator Fit Tester, a top-notch instrument, has received support from TSI® – a world-renowned leader in workflow management, software services, and measurement instruments.

As an industry leader, its exceptional professionals support its customers and authorised partners with their expertise, resources, and skills, ensuring they receive the best possible service. TSI offers a professional support network that matches the standards you would expect from a global leader.

TSI’s commitment extends from sales and training to exceptional technical support, customer service, product service, and calibration. It strives to empower industries to make informed, data-driven decisions and accomplish tasks efficiently.

To learn more, visit: TSI.com/PortaCount

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Lubrication-free igus spherical balls are available with cost-effective sheet metal housing, polymer housing or cast iron housing.

Frequent heavy dirt, dust, and swarf accumulation is common with pillow blocks and fixed flange bearings. This necessitates constant lubrication and maintenance. However, customers now have a solution with injection-moulded spherical insert bearings, which offer a maintenance-free and lubrication-free option for their metallic pillow blocks. Igus has expanded its range of high-performance polymer spherical balls for cost-effective sheet metal housings to enhance this offering further. These new components can be easily mounted in seconds and are readily available from stock. Additionally, igus has introduced dimensionally identical 1:1 replacements for pillow blocks and flange bearings, entirely made of wear-resistant plastic materials, including a high wear-resistant plastic ball and a heavy-duty plastic housing.

Metal and lubrication are found close together in mechanical engineering. igus proves that this can be different. The motion plastics specialist has developed its igubal exchangeable spherical insert bearing, especially for pillow blocks and fixed flange bearings with metallic housings. These consist of the high-performance polymer iglidur J, which reduces costs since lubrication and maintenance are eliminated. The use of polymers prevents dirt and dust from settling in the bearing. This additionally minimises the sealing and prevents unplanned machine downtime. The use of insert bearings is also suitable in agriculture, farming, the food industry, or plant and mechanical engineering. The igubal spherical insert bearing comes directly from injection moulding and is cost-effective. Within a few seconds, they can be mounted in place of ball bearings in existing classic metallic pillow blocks and flange bearing housings and now also in low-cost sheet metal housings. If a complete polymer pillow block or flange bearing is required with polymer housing, then it is also available directly from stock. The Igubal spherical insert bearing has high durability, and its service life can be easily calculated online.

Lubrication-free operation due to iglidur J

The spherical insert bearings made of iglidur J are cost-effective. They also have a very low coefficient of friction in dry operation. The material absorbs only a little moisture, so using the spherical insert bearings is also suitable outdoors. Due to the high-performance plastic’s chemical resistance, the exchangeable spherical insert bearing is also suitable for use in chemically demanding applications such as agricultural technology or even glass processing. iglidur J displays its advantages, especially in soft shafts. The igubal spherical insert bearings are currently available in five dimensions for low-cost sheet metal housings (Ø 17mm, 20mm, 25mm, 30mm and 35 mm) and cast housings (UC204-210). It is also available as a complete polymer pillow block of flanged bearing sizes UC203-210 and F203-210.

For more information visit us on www.igus.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Once more, the UNITED GRINDING Group will have a notable presence at EMO Hannover 2023 with a prominent booth in Hall 11, Booth E34. Spanning an extensive 1,000 m2 area, the group will showcase 16 machines featuring new and innovative products alongside exemplary offerings from the “Customer Care” section.

The UNITED GRINDING Group, renowned for its production of grinding, eroding, laser, and measuring machines and machine tools for additive manufacturing, has earned a reputation as a trailblazer in developing cutting-edge technologies within its industry. Emphasizing the “Innovate Manufacturing” theme, the group has deemed its presence indispensable at this year’s EMO Hannover event. Visitors can look forward to an expansive 1000 m2 exhibition space located at Hall 11, Booth E34, where they will be warmly welcomed.

Customer Care special exhibition area and machine highlights

At this year’s EMO, the UNITED GRINDING Group is dedicating a special exhibition area to focus on Customer Care, encompassing products and services that support customers throughout the entire lifespan of their machines, ensuring efficient production from “start-up” to “retrofit.” Visitors to the trade show will be able to explore comprehensive information about the group’s digital assistance systems, including the UNITED GRINDING Digital Solutions™ like Production Monitor, Service Monitor, and Remote Service. Additionally, other digital solutions will be showcased at EMO.

Exciting innovations and highlights await the public among the 16 machines displayed at the event:

BLOHM will unveil the PLANOMAT XT 408, a world premiere featuring automatic workpiece loading and unloading, catering to the internal machining of hydraulic motor stators. STUDER presents an innovative automation solution demonstrated on the S31 universal external cylindrical grinding machine. WALTER to introduce the groundbreaking “Laser Contour Check” measuring system, enabling precise, non-contact measurement of various tool parameters on cylindrical tools. This option is now available for the HELITRONIC MICRO and HELITRONIC MINI PLUS tool grinding machines.

Moreover, the showcased machines will feature cutting-edge C.O.R.E. technology, a pioneering hardware and software architecture that lays the foundation for a new generation of machine tools. This technology offers easy networking, intuitive smartphone-like operation, and the capability to use modern software applications directly on the machines.

United for your success

The motto and slogan of the group, “UNITED FOR YOUR SUCCESS,” perfectly encapsulates the essence of UNITED GRINDING. With its nine brands operating together, the group’s strength is harnessed to enhance the success of its customers, a commitment they have upheld for the past three decades. As they celebrate their 30th anniversary, the group is excited to showcase product highlights at the trade show and commemorate this milestone birthday. They eagerly anticipate personal conversations with their valued customers and the curious trade audience.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

BDK Valves and Gurukrupa Group acquire 100% stake in Theis Precision Steel India, a leading specialty cold rolled steel strips manufacturer, expanding their market presence and driving value for customers.

BDK Valves ( manufacturer of Industrial valves providing flow control solutions to global customers) and Gurukrupa Group (realty developer in western India), announced the acquisition and controlling (100%) stake in Theis Precision Steel India Pvt. Ltd. (Theis Precision). This is the second acquisition of international companies by the promoter group to serve customers in India & across the world.

Theis Precision, formerly owned by Tata Steel Ltd., is a pioneer in specialty cold rolling of high/medium carbon steels in India. Today, it is a leading specialty cold rolled steel strips manufacturer in the country. It also is the only manufacturer of precision hot rolled solid steel profile sections, by a unique process, to satisfy the customers whose needs may be small in quantity but expectations are large.

Theis Precision caters to the need of various market segments such as automotive, textile machinery, cutting blades/saws, office machinery, general engineering, etc. It is specialised in catering to customized requirements such as desired surface finish, roughness, tempering, dimensional tolerances and packaging. In addition, the division has the capability of supplying hot rolled solid profiles, cold drawn profiles and profiles in ready-to-use form. Theis Precision’s latest addition in the product portfolio is Hardened & Tempered strips with a unique environment friendly Quench Media.

Arjen Rijpkema, CEO, Mahler Asia BV in the Netherlands, said, “This sale of Theis Precision Steel to BDK and Gurukrupa brings it back to Indian family ownership after Theis Gmbh in Germany (which was owned by Mahler Asia) acquired it from Tata Steel in 2008. We are convinced that the new owners will contribute strongly to the further development of the company. They bring in-depth knowledge of the steel market, manufacturing and real estate experience which all can strengthen the business. They are geographically much closer to the plant enabling them to be more hands-on and directly involved as promotors than we could ever be from the long distance in Europe. Further I am certain that the new owners will professionally steer Theis Precision towards modernization and accelerated growth, which is fundamental to the business.”

Shyam Mehta, Director, Theis Precision Steel India, said, “The acquisition of ‘one-stop one-window’ Theis Precision Steel is a unique value-enhancing deal bringing a pioneer in specialty cold rolling of high/medium carbon steels into our fold. This acquisition expands our portfolio presence and showcases our commitment to drive value for our customers. As a leading specialty cold rolled steel strips manufacturer in the country, Theis Precision is the only manufacturer of precision hot rolled solid steel profile sections by a unique process, to satisfy the customers whose needs may be small in quantity but expectations are large. We look forward to combining BDK Valve’s capabilities with the talent and expertise brought by Theis Precision’s team as we expand our market presence.”

Chetan Kothari, Director, Theis Precision Steel India, said, “With the backing of BDK Valves and Gurukrupa Group, Theis Precision Steel can now become an undisputed leader in its market segment and accelerate growth & expansion. The diversification in manufacturing and synergies in terms of manufacturing facilities, processes and products will give us an edge and add to the products and services offered by us to customers. Theis Precision Steel has products across sectors such as agriculture, automotive, construction, cutting tools, earthmoving and textile machinery among others. We will further invest capital in the company to quadruple our volumes to be a global player in speciality steel business.”

Theis Precision’s Cold Rolling Division, established in 1968, pioneered in India cold rolling of stainless steel and later focused on cold rolling of narrow width strips in mild, medium and high carbon and low alloy steels. It has a manufacturing capacity of 40,000 M.T. per annum. The Profiles Division, established in 1997 has a manufacturing capacity of 6000 M.T. of custom made solid profiles/sections in various grades of steel. Hardened & Tempered Division, established in 2022 has a manufacturing capacity of 4000 MT of H&T strips in high carbon and alloy grades of steel for various applications ranging from woodworking saws, Blades like Gangsaw/Bandsaw, with required edge conditions. Immediate target is to increase manufacturing capacity from 40000 MT to 150000 MT per annum, enhancing our market share in domestic & global markets.

Bathiya Legal were the sole legal advisors and Bathiya & Associates LLP Chartered Accountants were Financial Advisors.

BDK Valves is a leading manufacturer & exporter of valves since last 45 years providing flow control solutions to customers across the world. Our portfolio includes engineered valves for high pressure applications to standard isolation valves of sizes ranging from 15mm to 4500mm. BDK caters to the need of various market segments such as Oil & Gas, Power, Mining, Steel, Food & General industry. The company is decorated with a lot of key certifications such as; API 6D, PED 2014/68/EU Annex III, Module H, SIL-3, CUTR. It continues to focus on sustainable growth by investing in people & equipment doubling the sales in FY 2023-24.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Dalmia Bharat Limited (DBL) commences commercial production at its new 2.0 MnT Greenfield Cement Grinding unit in Sattur, Tamil Nadu, reinforcing market presence and catering to the growing demand in the South.

Dalmia Bharat Limited (DBL), a leading Indian cement major under its wholly owned subsidiary Dalmia Bharat Green Vision Limited (DBGVL) announced the commencement of commercial production at its new Greenfield Cement Grinding unit in Sattur, Tamil Nadu. This new unit adds 2.0 million tons of cement capacity to the company’s overall installed capacity, bringing it to a total of 43.7 million tons. With an investment of Rs.686 crores, the new cement grinding unit will produce cement, supported for the clinker requirements from the existing Integrated plants in Tamil Nadu. This strategic move is part of the company’s plan to strengthen its market presence in the South and to cater to the growing demand in the region.

Dalmia Bharat’s strong bond with the region is rooted in its legacy, as the company’s first cement plant was established in Dalmiapuram, setting its foundation in the industry. The new cement grinding unit is equipped with the latest advancements in environmental-friendly technology for low carbon footprint. A 16 MW solar power capacity installation is in process to support its renewable energy initiative. With advanced automation and digitalization systems, the plant ensures higher operational efficiency and enhanced safety measures.

Commenting on the company’s expansion plans, Mr. Puneet Dalmia, Managing Director, Dalmia Bharat Limited, said, “Amidst a robust real estate cycle and a sustained push by the Government on infrastructure, we find ourselves in a dynamic and strong demand environment. South is a fast-growing market and we are expanding our capacity to meet the rising cement demand in the region.”

Dalmia Bharat has long-term growth and investment strategy aimed at expanding its installed cement capacity to a substantial 110-130 million tonnes by the year 2030-31. The company’s growth approach includes a judicious combination of organic and inorganic opportunities, with a focus on a well-planned and cost-effective organic route.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Swiss Steel Group is pioneering Green Steel for Automotive Innovation. Delivering versatile and eco-friendly specialty steels, enabling lightweight construction, fuel efficiency, and high-performance components for the ever-changing automotive industry.

The automotive market is undergoing constant change – special steels in Green Steel quality are becoming increasingly important and only a few can already supply them.

It is not just a question of producing low-CO2 powertrains, but also of meeting requirements for ever lighter, safer and more comfortable vehicles with alternative powertrains.

With its specialty steels, the Swiss Steel Group is helping to successfully master these increasingly pressing challenges.

In the production of automobiles, manufacturers and designers must be able to rely on the versatility and performance of the material for components and systems. It must be produced with low CO² emissions and the material must also be affordable. This is what the Swiss steelmakers deliver. The Swiss Steel Group produces consistently high-quality, reliable and customized solutions for engine components, high-pressure pumps, exhaust systems, chassis components, hydraulic and pneumatic systems, and airbags.

Steel expertise for the automotive industrie

Green steel and lightweight construction are the order of the day for reducing fuel consumption in conventional powertrains or optimizing the range of electric vehicles. The Swiss Steel Group has a solution ready for automotive suppliers for all special applications, the perfect steel.

The Swiss Steel Group with its plants, Deutsche Edelstahlwerke, Ugitech, Steeltec and Sorel, is one of the leading developers and suppliers of engineering steel, stainless steel and tool steel. The Group’s own research and development departments are in regular contact with customers, keep their ear to the market, and help shape the future of auto manufacturing thanks to innovative solutions.

When it comes to lightweight components, for example, the innovative Bainidur 1300 from Deutsche Edelstahlwerke can be used to produce sophisticated forgings cost-efficiently. This bainitic material can be processed without distortion and with only a small amount of machining allowance without further complex process steps. The use of this material makes it easier for manufacturers to produce parts of consistently high quality without additional quenching and tempering and without the risk of warpage. And this also applies to large-format parts (> 60 mm round).

Less inspection effort for manufactured parts

The Bainidur 1300 allows a wide process window with regard to temperature control during forging and cooling. The bainitic microstructure and the properties of the component can be reliably adjusted, and the testing effort of manufactured parts is reduced.

“The material is the ideal solution for heavily loaded parts and at the same time significantly reduces material usage compared to conventional steel, with comparable load values,” emphasizes the Head of Technology & Quality at Deutsche Edelstahlwerke of the Swiss Steel Group.

Bar steel is already installed in almost every vehicle today: up to 300 kg of engineering steel and up to 10 kg of stainless steel, because every weight saving thanks to innovative products means lower gasoline consumption, greater range and above all conservation of resources.

When it comes to demanding applications

The heat-resistant steel Thermodur® 2383 Supercool from Deutsche Edelstahlwerke, for example, ensures shorter cycle times in the production of sheet metal components such as the B-pillar: Used for press hardening tools, Thermodur® combines hot forming and heat treatment – significantly reducing process costs.

Excellent purity characterizes the plastic mold steel SF-2000® LQ40 from Sorel Forge. This makes it suitable for mirror polishing: This gives headlight lenses a crystal-clear surface and allows them to be permanently reproduced in high quality.

The HSX® 90 steel from Steeltec ensures that the airbag sleeve can be welded within a very short time so that the propellant introduced does not escape. On top of this, the high-strength special steel withstands enormous pressure until the airbag is triggered.

Splitasco XS for lighter and stronger connecting rods

Ascometal has been very successful in developing and supplying its Splitasco HC steel grade. With this, Ascometal has launched a steel grade that the company developed in close cooperation with a specialist in connecting rod production. The new steel grade enables a further improvement for connecting rods in lightweight construction and higher load transmission.

Splitasco XS meets two key customer requirements, namely maximum compressive load without plastic deformation and increased fatigue strength. Compared to the standard C70 grade, the compressive yield strength is increased by 110% and the fatigue strength by more than 60%. These very high application properties can significantly reduce the weight of the manufactured parts.

Outstanding mechanical properties

As bainitic steels the mechanical properties of the parts produced with Splitasco XS are achieved without quenching, thus avoiding distortion of the components. Furthermore, by optimizing the chemical composition, a fully bainitic microstructure can be achieved with respect to different cooling rates. As a result, connecting rods weighing several kilograms can be manufactured with the same mechanical properties as smaller ones weighing only 500 grams.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

DeburringEXPO – The 5th leading international trade fair for deburring technology and precision surface finishing, showcasing cutting-edge solutions for diverse industries at Karlsruhe Exhibition Centre, Germany, from October 10 to 12, 2023.

Whether the mobility and energy transition, sustainability, health or safety is involved – global megatrends have a profound effect on industrial production. They’re also impacting demands placed on burr-free components, as well as cleanliness and surface finishing quality. As the only international trade fair for deburring technologies and precision surface finishing, DeburringEXPO presents corresponding offerings in a concentrated fashion which is unparalleled by any other event. The bilingual expert forum and various theme parks will also ensure an effective transfer of knowledge at the 5th leading trade fair at the Karlsruhe Exhibition Centre from the 10th through the 12th of October, 2023.

Components and the demands placed on their performance and reliability have changed dramatically in recent years in areas such as automotive and machinery manufacturing, medical and pharmaceuticals technology, aviation and aerospace, energy and fluid technology, as well as measuring, sensor and analysis technology. This results in new and different tasks in production steps involving deburring, edge rounding, cleaning and surface finishing. At the same time, factors such as the energy and resource efficiency of the utilised processes and their integration into interlinked production are becoming increasingly important. As a leading international information and procurement platform, DeburringEXPO presents new and further developed, as well as time-tested solutions to this end. The 5th leading trade fair for deburring technology and precision surface finishing will be held at the Karlsruhe Exhibition Centre in Germany from the 10th through the 12th of October, 2023.

The Right Process for Every Application

“Thanks to its multi-industry, multi-material focus, DeburringEXPO supports companies from all industry sectors in their search for suitable processes,” reports Gitta Steinmann, project manager at private trade fair promoters fairXperts GmbH & Co. KG. “The entire spectrum of technologies, processes, tools and services for deburring, edge rounding, cleaning and surface finishing are presented. The strengths and the limits of the various processes ranging from mechanical deburring with tools to vibratory grinding, brush deburring and blasting with solid and liquid media, right

on up to machining with special technologies, can be discussed directly on site.” The latter includes, for example, ultrasonic deburring which makes it possible to selectively deburr edges and cross-drilled holes in a fully automated, verifiable process. Since this energy-efficient process can be used for nearly any material, the range of suitable workpieces covers everything from micro parts for the optics and watchmaking industries to precision tools for machining, all the way up to components used in machinery and vehicle manufacturing weighing 15 kilograms.

Abrasive flow machining (AFM) also covers a very broad range of applications. It’s used for the deburring, edge rounding and polishing of components in the automotive and aviation industries, as well as in energy technology, fluid and medical engineering, extrusion technology and mould and tool making. The strengths of this process result from its ability to machine internal areas and surfaces which are difficult to access, for example in additively manufactured components.

In the case of ECM (electrochemical machining), the machining process is based on the anodic dissolution of the respective metal. Nearly all metals can be machined, in particular high-alloy materials such as nickel-based and titanium alloys, and hardened materials. In addition to deburring, selective edge rounding and polishing, the technology is also used for contouring and shaping components, as well as for burr-free drilling – for example in the aviation and aerospace industry, the automotive and toolmaking sectors, as well as in medical, microsystems and energy technology.

Laser deburring is an effective method for removing fine burrs and flakes from the outer contours of very delicate, thin-walled workpieces. Even the edges of drill holes with diameters of just a few tenths of a millimetre can be machined. The process is also distinguished by very high processing speeds.

Thermal energy machining (TEM) permits the simultaneous removal of external and internal burrs by means of vaporisation. It’s used primarily for metal workpieces such as hydraulic manifolds, and for components made of thermoplastics from which internal and external burrs have to be removed – even from very difficult-to-access places.

Bilingual Expert Forum – Effective Knowledge Transfer for Added Value As a complement to the exhibitor presentations, the supplementary programme at DeburringEXPO offers a great deal of knowledge and know-how. Theme parks including “Automated Deburring”, “Cleaning After Deburring” and “Quality Assurance in the Deburring Process” provide information on current developments and trends. Due to its highly practical orientation, the 3-day expert forum integrated into DeburringEXPO is an extremely popular source of knowledge. The focal points of the simultaneously interpreted presentations (German <> English) include fundamentals, approaches to process and cost optimisation, reports on best practice applications and current trends, as well as special content provided by the theme parks. Trade fair visitors are admitted free of charge and will also receive a free copy of the updated and expanded brochure entitled “Basic Knowledge in Deburring Technology” in German and English.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Nitin Jirafe, the Engine Business Leader at Cummins India, highlights that the automotive industry has effectively addressed complex challenges by integrating and utilising Industry 4.0 technologies. The automobile industry is poised to navigate towards a more sustainable future by continuously incorporating and leveraging these technologies.

How is the Indian automotive industry adapting to meet the latest safety and emission standards while embracing advancements in electric and hydrogen-powered vehicles?

The Indian automotive industry is experiencing growth on various fronts. Factors such as strong economic growth, a youthful population, and increasing urbanisation are driving volume growth. Simultaneously, the industry is adapting to meet the latest safety and emission standards, aligning with global benchmarks and increasing the value and content of vehicles. The government’s focus on infrastructure projects further fuels the demand in this sector.

Moreover, the automotive industry in India is undergoing a transformative shift propelled by advancements in electric and hydrogen-powered vehicles, technological integration, manufacturing excellence, and research and development. The nation is actively transitioning toward zero-emission mobility, driven by the government’s ambitious goals of reducing vehicular emissions and dependence on fossil fuels. This shift has led to the development of ecosystems for hydrogen-based fuel cells and internal combustion technology, representing the future of mobility.

The industry is leveraging digital technology to enhance vehicle efficiency, safety, and connectivity. Artificial intelligence (AI) and data analytics are being integrated into vehicle systems to enable monitoring and predictive maintenance. India’s commitment to developing world-class manufacturing capabilities has been instrumental in shaping its automotive industry.

By embracing sustainable mobility solutions and driving innovation, the Indian automotive sector is poised to have a significant global impact. This reflects the country’s growing economic strength and its dedication to a greener and technologically advanced future.

How is the industry leveraging 4.0 technologies for sustainability in the automobile industry?

The automotive industry has quickly adopted technological advancements to enhance efficiency and address sustainability concerns. Industry 4.0 encompasses a range of digital technologies that enable automation, connectivity, and intelligent decision-making. These technologies offer valuable tools for the automotive industry to reduce its environmental impact and promote sustainable practices.

These Industry 4.0 technologies, including artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT), enable the implementation of intelligent manufacturing processes. By leveraging data-driven insights, automotive manufacturers can optimise production efficiency, minimise energy consumption, and reduce waste. By utilising Industry 4.0 technologies, automotive manufacturers can achieve the following:

· Enhance supply chain optimisation, resulting in reduced energy usage and emissions.

· Streamline logistics processes through advanced data analytics and AI algorithms, minimising unnecessary transportation and improving inventory management.

· Real-time insights enable better control over resource utilisation, leading to a decreased environmental impact.

· Connected factories provide end-to-end visibility of the entire supply chain, including product quality and process capability, which support in anticipating issues ahead of time. These are helping to shift the manufacturing and supply chain mindset from reactive to proactive and predictive way of working.

The integration and utilisation of Industry 4.0 technologies have effectively equipped the automotive industry to tackle complex challenges. Integrating and leveraging these technologies will undoubtedly steer the automobile industry towards a more sustainable future.

How can software and technology providers leverage the growing demand for electric vehicles?

The electric mobility automobile sector has witnessed substantial growth recently. With the increasing demand for electric vehicles, there are numerous opportunities for software and technology providers to capitalise on this emerging market. One key opportunity lies in the development of advanced charging infrastructure. As more electric vehicles hit the road, efficient and widespread charging stations become crucial. Software and technology providers can seize this opportunity by creating innovative solutions to optimise the charging process, such as smart charging algorithms and real-time monitoring systems. By offering convenient and seamless charging experiences, these providers can promote the adoption of electric vehicles and contribute to the sector’s overall growth.

Furthermore, software and technology providers can focus on developing intelligent energy management systems. Electric vehicles not only require charging but also need efficient management of their energy consumption. By leveraging advanced software and technology, providers can design intelligent systems that optimise energy usage by considering factors like battery capacity, driving patterns, and external conditions. This optimisation can result in extended battery life, improved range, and enhanced overall performance of electric vehicles.

There are ample avenues for innovation and growth in advanced charging infrastructure, intelligent energy management systems, vehicle-to-grid technology, and autonomous capabilities. Software and technology providers, with their expertise and creativity, can play a pivotal role in shaping the future of electric vehicles and contribute to building a sustainable and efficient transportation ecosystem.

How have robotics and 3D printing technologies revolutionised automotive manufacturing?

The automotive industry has rapidly embraced technological advancements, particularly in integrating robotics and 3D printing, which have transformed vehicle design and manufacturing processes. Implementing robotics and automation has significantly enhanced efficiency and productivity, reducing production time, improving accuracy, and enhancing quality control.

3D printing technology has helped streamline the manufacturing process by enabling the rapid development of parts and components. This technology offers numerous advantages, including creating intricate designs, minimising material waste, and producing lightweight yet durable components. Furthermore, 3D printing allows for customisation, facilitating the production of tailor-made parts that cater to individual customer preferences.

Integrating robotics and 3D printing has become essential in the ever-evolving automotive industry, driving innovation, efficiency, and sustainability. As these technologies continue to advance, we can expect further groundbreaking developments that will shape the future of mobility. Additionally, these technologies enable the upskilling of the workforce and offer opportunities for existing employees to move up the value chain.

How do you evaluate Make in India and the Atmanirbhar concept that propagate indigenous manufacturing?

India’s economic landscape has undergone significant transformations with the introduction of initiatives like Make in India and Atmanirbhar. These initiatives aim to promote indigenous manufacturing and self-reliance. The Atmanirbhar concept emphasises the importance of self-reliance and domestic manufacturing with a primary objective to reduce India’s dependence on imports, particularly in strategic sectors, and instead encourage domestic production. This concept gained prominence during the COVID-19 pandemic, which exposed vulnerabilities in global supply chains.

Make in India has attracted foreign direct investment and encouraged multinational corporations to establish manufacturing units. This has created employment opportunities and enhanced technological capabilities and skill development. These initiatives have facilitated the growth of the manufacturing sector, a vital component of economic progress.

The government has introduced Production Linked Incentives (PLI) schemes to support domestic manufacturing for future technologies further. As the Automotive industry takes transformative steps towards zero-emission technologies, the PLI scheme will help build the ecosystem and enable India to become a hub for these future technologies.

The Make in India initiative and the Atmanirbhar concept are crucial to promoting domestic manufacturing and achieving self-sufficiency. Their effectiveness will rely on successful implementation, addressing challenges, and creating a conducive business environment. By evaluating these initiatives and making necessary adjustments, India can strengthen its manufacturing sector, drive economic growth, and achieve long-term sustainability.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Talking about the EV ecosystem, Vikas Puri, Business head, Cosmo Ferrites, says we remain dedicated to pioneering innovative solutions and playing a crucial part in shaping the future of sustainable transportation.

What specific strategies or technologies do your solutions employ to help manufacturing units reduce their carbon footprints and promote sustainability?

Our solutions have been purposefully designed to enable sustainability within manufacturing units. We specifically focus on reducing carbon footprints, implementing low-emission or zero-emission practices, and promoting individuals’ health, safety, and well-being. Firstly, we prioritise the reduction of carbon footprints by incorporating environmentally conscious practices and technologies. We actively work towards reducing greenhouse gas and toxic emissions by employing energy-efficient methods and renewable energy sources. Implementing these sustainable practices allows manufacturing companies to actively contribute to a greener future and demonstrate their commitment to environmental stewardship.

Furthermore, our solutions strongly advocate for adopting low-emission or zero-emission practices. Through close collaboration with manufacturers, we encourage the integration of clean and sustainable energy sources, such as solar or wind power, and using electric vehicles and machinery powered by renewable energy. These initiatives significantly reduce environmental impact, showcasing our dedication to sustainable operations within manufacturing units. Additionally, our solutions prioritise the well-being and safety of individuals by fostering a culture of protection and care. By prioritising the health and safety of the workforce, we ensure their well-being and enhance productivity and overall morale.

Can you talk about the quality management system at your facility?

At Cosmo Ferrites, we ensure that our Quality Management System is error-free to ensure the finest quality output. The QMS has four processes: Statistical Process Control (SPC), Lean Six Sigma, Total Preventive Maintenance (TPM), and Failure Mode Effect Analysis (FMEA). Following the techniques and practices, we reduced customer complaints (FY 2020-21 vs 2021-22) by 30 percent. For material characterisation & quality control, our manufacturing facilities are equipped with the following:

- XRF: for determination of material composition and purity level accurately

- Particle size analyser: for determination of particle size distribution in powder material

- Computerised BET surface analyser: for determining the specific surface area of powder materials

- Programmable climatic chamber: for evaluating temperature-dependent electromagnetic properties of ferrite materials in a wide range of -85°C to 180°C

- Computerised strength testing machine: for determining bending / tensile strength of sintered ferrites at a defined load profile

What practices are helping in reducing carbon footprints?

At our organisation, we have implemented a range of practices that have significantly impacted reducing our carbon footprint. These practices are integral to our commitment to promoting sustainability and taking responsibility for the environment. Firstly, we have embraced energy-efficient technologies and processes across all operations. This includes adopting energy-efficient lighting systems and implementing smart energy management systems that effectively minimise our energy consumption. By reducing our energy usage, we decrease our carbon emissions and achieve tangible cost savings.

Furthermore, we have substantially invested in renewable energy sources to power our facilities. We have successfully installed solar panels on our premises and have established partnerships with local renewable energy providers to leverage wind energy. By transitioning to clean and renewable energy sources, we significantly reduce our reliance on fossil fuels, reducing our carbon emissions.

Furthermore, we have implemented waste reduction and recycling programs. We strive to minimise waste generation by implementing lean manufacturing practices and optimising our supply chain. We continuously monitor our environmental performance, set ambitious targets, and explore innovative solutions to enhance our sustainability efforts further and minimise our environmental impact.

- Installation of solar panel– Approx. 2500 Kw-hr electricity generated daily.

- Usage of LPG in place of diesel in ferrite processing– Approx. 125 kg diesel saved daily.

- Water recycling– Approx. 15,000 litres of water saved daily through recycling.

How Industry 4.0 & 5.0 do reshape manufacturing practices?

The convergence of Industry 4.0 and Industry 5.0 is reshaping the manufacturing landscape in India, bringing forth a new era of technological advancements and digital transformation. This convergence of technologies, including digital twins, artificial intelligence (AI), machine learning (ML), robotics, augmented reality (AR), and virtual reality (VR), is revolutionising the global market and how manufacturers operate. Digital twins, virtual replicas of physical assets, allow manufacturers to simulate and optimise processes, resulting in improved product design, predictive maintenance, and increased operational efficiency. MANUFACTURERS CAN MAKE DATA-DRIVEN DECISIONS through AI and ML algorithms, leverage predictive analytics, and optimise processes, leading to enhanced production lines, improved quality control, and reduced downtime.

The adoption of robotics and automation technologies has revolutionised manufacturing operations, enabling precise and efficient execution of repetitive tasks while allowing human workers to focus on higher value-added activities. Collaborative efforts between humans and machines have significantly enhanced operational efficiency, productivity, and workplace safety. Additionally, AR and VR technologies offer immersive experiences that enable workers to visualise and interact with digital information within the physical environment. These technologies have proven beneficial for training, maintenance, and collaborative efforts, increasing productivity and reducing errors. By embracing these transformative technologies, India can establish itself as a global manufacturing leader, driving innovation, economic growth, and job creation. By utilising the potential of Industry 4.0 and Industry 5.0, Indian manufacturers can unlock new opportunities, enhance efficiency, and thrive in the digital age.

How does the development of advanced ferrite materials at Cosmo Ferrites enhance electronic component performance?

Cosmo Ferrites is constantly upgrading its technology, focusing on developing advanced ferrite materials and products. The new series of products is committed to enhancing the performance of the electronic components. Ferrite materials operating at higher frequencies (MHz /GHz level) improve the system’s efficiency through miniaturisation and find their noble application in advanced electronic systems like AI.

What steps can be taken to address the challenges related to technological infrastructure, regulatory environment, and skilled labour in India’s manufacturing sector?

One of the primary obstacles to modernising manufacturing facilities in India is the need for more technological infrastructure. To boost the competitiveness of the manufacturing sector, it is crucial to establish a robust technological infrastructure that includes reliable communication networks, efficient transportation systems, and a skilled workforce. However, the availability of telecom facilities is predominantly concentrated in major cities, limiting access and connectivity for manufacturing units in remote areas. Insufficient infrastructure, including power supply and telecommunications, poses challenges to the smooth functioning of manufacturing operations and hinders sectoral growth.

Another significant challenge lies in the regulatory environment. India’s regulatory framework often involves complex processes and bureaucratic hurdles, which create barriers for businesses intending to establish manufacturing units. Despite some progress, India’s ranking in the ease of doing business has shown limited improvement, highlighting the need to streamline and simplify regulations to facilitate manufacturing activities. Addressing these regulatory challenges and fostering a business-friendly environment is crucial for attracting investments and promoting the growth of the manufacturing sector. Additionally, there is a need for more skilled labour, which presents a pressing concern. The education system in India needs to adequately adapt to the changing demands of the economy, resulting in a mismatch between available skills and industry requirements. Bridging the skill gap and cultivating a skilled workforce is essential for achieving self-reliance in manufacturing. Prioritising vocational training and implementing robust upskilling programs can help address this challenge, ensuring that the manufacturing sector has access to competent and qualified workers.

Overcoming these challenges requires a comprehensive approach that involves improving infrastructure, simplifying regulations, and investing in skill development initiatives. By effectively tackling these issues, India can create an enabling environment for modernising manufacturing facilities, fostering growth, and enhancing competitiveness in the global market.