The Indian Machine Tool Manufacturers’ Association (IMTMA) is launching FACTEQ 2024, India’s premier expo for complete factory solutions, from May 23-26, 2024, in Pune. Explore cutting-edge factory equipment under one roof.

Indian Machine Tool Manufacturers’ Association (IMTMA), organizer of IMTEX is launching FACTEQ 2024, a first-of-its-kind expo in India focusing on complete solutions for factories. The expo will be held from May 23 – 26, 2024 at the Pune International Exhibition and Convention Centre, MOSHI, Pune.

FACTEQ 2024 would bring the entire range of factory equipment required to design, build, maintain and upgrade factories, under one single roof. Exhibitors would display cutting-edge factory solutions to meet the requirements of various industry sectors. FACTEQ 2024 is co-located with Pune Machine Tool Expo, western region’s leading machine tool and manufacturing technology exhibition.

Jibak Dasgupta, Director General & CEO, IMTMA stated: “As India’s manufacturing industry moves towards contributing $1 Trillion to the economy by 2030, industries are expected to grow multi-fold resulting in demand for new factories and necessitating upgradation of existing factory setups. Considering these factors IMTMA has come up with FACTEQ 2024 which is a unique model in India which enables customers to source safe, sustainable, and environment-friendly solutions for the factories of tomorrow.”

Further information about the show is available on www.facteq.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Planetary gearboxes are prescribed in 2 different situations: as a one-to-one replacement of a competitor product, or in a new customer development. Recommending an alternative product in an existing application is an easy task, as our engineers know that their design is safe.

Reckon gearboxes can replace gearboxes of similar size and interface at no risk. In the second case, when customers design new systems, it is our responsibility to recommend a reliable solution that matches all specifications. From a customer perspective, determining the appropriate gearbox size using standard catalogs is becoming viewed as unreliable and fraught with risk. More and more engineers are beginning to question the accuracy of the values provided in datasheets. Personally, we hold the belief that the recent uptick in reported product performance by certain suppliers is puzzling and cannot be attributed solely to improvements in design, materials, treatments, or lubricants.

Customers now expect that manufacturers proceed to argued recommendation, based on solid, reliable data.

Explaining the discrepancy between our torque ratings and those of our competitors to our customers is a challenging task. This is because when it comes to assessing gearbox torque ratings, there can be significant variation. For instance, ten different gear designers may assign ten different torque ratings to the same gearbox. These variations are influenced by factors such as the specific norms or norm versions they follow, the safety margins they choose to incorporate, and the scenarios they consider in their calculations, such as speed, heat, and the location of shaft loads.

To address this question effectively, one would need to understand the methodology used to calculate the torque ratings, which is often not provided in catalogs. It’s essential to recognize that the gearbox with the highest torque rating isn’t necessarily the best choice. In fact, it may indicate that safety margins have been reduced to present more favorable data, which we consider to be potentially misleading.

In our industry, when datasheet ratings are genuinely provided, they often rely on standards that assume an ideal scenario where every component is precisely positioned and manufactured. In this idealized scenario, the performance of each individual part is not influenced by the interactions with other components both inside and outside the gearbox. It also assumes that any radial loads on the shaft only affect the gearbox’s output bearings or the shaft itself. However, the reality in practical applications is quite different.

Romax Enduro functions

As it is able to take all these parameters into account, Romax Enduro estimates real-life conditions more accurately than any other software we used before. We can show how our products behave in any application.

While natively integrating most calculation norms including the latest updates of the ISO 6336-2:2006 for gear calculation and the TS 16281:2008 for bearing calculation, English company Romax goes further and works with the most respected experts around the world to develop their own additional algorithms. Functions now available in Romax Enduro enable increasing design reliability and estimating very precisely the life of a complete gearbox, taking all aspects of real-life conditions into account. Using Romax, we can now estimate the life of each gearbox in our customers application, component by component, taking into account the impact on a component on the other, and, more importantly, considering your output element as a part or the system.

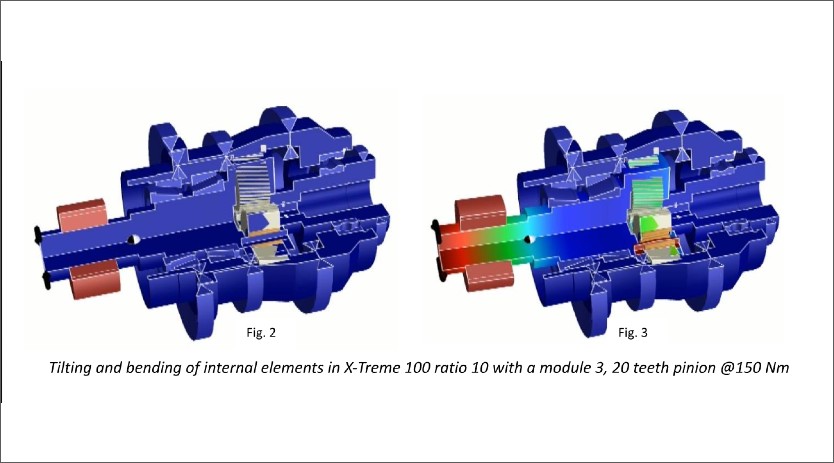

The following phenomenon is typical: in a rack and pinion transmission, the combined loads generated by the helical pinion are applied to the output shaft, they bend it, tilt it around the output bearings, twistthe planet carrier, which compresses the ring gear onto the gears, the needles against the planets, the planets against the sun gear and finally applies a radial load on the customer motor shaft! As a result the sun gear suffers more than what the basic norms can estimate (basic algorithms will only give L10h results) and becomes the weak element in the system. Romax Enduro can tell us the damage to each of these elements!

The result of such calculation is obviously conservative when compared with standard datasheet ratings: in such or such application or working conditions, the same gearbox can be rated a certain torque value or only half of this value; but it is a fact that shafts, bearings, planet carriers, gears, needles, axles; all have their own stiffness. Who would prefer trusting catalog values that do not consider such a phenomenon?

Using Romax Enduro consequently makes our recommendations precise and professional: we now can tell you the difference in any internal element lifetime if you use a 25 teeth pinion rather than a 20 teeth pinion, as the resulting additional shaft torsion, flexion and tilt will reduce the size of the zone where the planets are transferred power from the sun gear, or transfer this power to the ring gear (this factor called the Khβ is clearly displayed in the results). Our engineers can show you that a 160 Nm gearbox is only a 120 Nm gearbox if you install a spiral bevel gear on its output shaft, because the radial and axial load generated by the bevel gear set will compress and deform the output bearings and tilt all the components inside above this torque. We can tell you that adding 2 teeth to your pinion and increasing the ratio slightly can sometimes increase, sometimes decrease the overall life, depending on the initial ratio.

Because even the greatest products cannot perform if poorly sized, we are ready to give our customers the perfect recommendation so their application achieves the longest lifetime and the best performance.

Expertise shared by: Martin MIJNO, CEO and founder of Reckon Drives International SAS, France.

For more information and assistance on improving your reliability, contact us at:

Amcats Pvt. Ltd., Turbhe, Navi Mumbai 400705.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Teledyne FLIR introduces Neutrino Ground ISR 300 and Ground ISR 420, advanced MWIR imaging solutions for ground-based ISR systems. These systems offer high-performance imaging and flexibility for surveillance and reconnaissance applications.

Teledyne FLIR, part of Teledyne Technologies Incorporated, announced two additional mid-wave infrared (MWIR) imaging solutions for integrators developing ground-based intelligence, surveillance, and reconnaissance (ISR) systems. The Neutrino Ground ISR 300 and Ground ISR 420 offer high-performance imaging, long life, and a low switching cost through the combination of Teledyne FLIR’s best-in-class MWIR camera modules, continuous zoom (CZ) lenses and image processing with market-leading control electronics from InVeo Designs LLC.

“The Neutrino Ground ISR series incorporates multiple focal plane array (FPA) resolutions and CZ lens options, all with the same industry standard image processing and interface electronics, allowing for differing detection recognition and identification (DRI) requirements and affordability,” said Dan Walker, vice president of product management, Teledyne FLIR. “As the most complete and versatile integrated MWIR solution yet for ground-based ISR systems, the newest addition to the Neutrino series delivers the performance, reliability, and support expected from Teledyne FLIR.”

To drive high system-level performance, the Neutrino Ground ISR series includes industry-adopted AgileCore™ imaging electronics, long-life Linear Stirling coolers that provide a superior mean-time-to-failure of greater than 27,000 hours, and fully integrated CZ optics. Developed and produced by Teledyne FLIR, formerly New England Optical Systems (NEOS), which joined FLIR in 2019, the CZ lenses provide a range of focal length options to maximize DRI. The series also features an industry-leading two-year warranty.

With the choice of either 640×512 or 1280×1024 thermal pixel resolution, the modules provide optimal thermal sensitivity while the zoom, focus, and boresight retention enable superior autofocus and focus-to-range. They also feature common camera interfaces with 30Hz Camera Link or Gigabit Ethernet and 1080P30 HD-SDI or 720P60 HD-SDI to streamline development further.

All Neutrino Ground ISR products are manufactured in the USA, classified under US Department of Commerce jurisdiction as EAR 6A003.b.4.a, and are not subject to International Traffic in Arms Regulations (ITAR). Customers also have access to a comprehensive software development kit (SDK), integration support, and documentation from the highly qualified technical services team at Teledyne FLIR.

The Neutrino Ground ISR products are upgradable to operate Teledyne FLIR’s AI detection, tracking, and classification models and image signal processing (ISP) libraries for super-resolution, turbulence mitigation, contrast enhancement, and more that will be available in 2024.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The 63rd Annual Convention of the Society of Indian Automobile Manufacturers (SIAM) places sustainable mobility at its forefront, featuring key insights and government initiatives for a greener automotive future.

Society of Indian Automobile Manufacturers (SIAM), the apex body representing leading automobile manufacturers of the country, commemorated its 63rd Annual Convention deliberating on the way ahead for Sustainable Mobility.

On the Occasion of 63rd SIAM Annual Convention Hon’ble Prime Minister of India, Shri Narendra Modi in his message mentioned that for over six decades SIAM has been serving the Nation admirably. He said India is the 5th largest economy and is soon poised to reach top 3. Hon’ble Prime Minister also noted Indian Auto Industry’s efforts towards decarbonization through introduction of vehicles with wide range of powertrain technologies. By 2047, we aspire to realize the vision of building a sustainable, self-reliant, strong and developed India.

The inaugural session, themed “Sustainable Mobility – The Way Ahead for Indian Automobile Industry”, Chief Guest, Nitin Gadkari, Union Minister of Road Transport & Highways, Government of India commented, “In 2014, the global automobile sector was ranked 7th, but today, it has climbed to the 3rd position. The automotive sector serves as a growth engine for our nation, aligning perfectly with the honorable Prime Minister’s vision to elevate India from its current fifth largest economy in the world to third. Our ultimate goal is to become the world’s leading automobile hub.” He requested the auto industry to work on expeditiously increasing the share of green technologies, such as biofuels, electric and hydrogen. Higher use of biofuels will lead to aligning the auto industry’s approach with global biofuel alliance announced during the G20.

Guest of honor, Dr Mahendra Nath Pandey, Union Minister of Heavy Industries, Government of India said, “India’s commitment to achieving net-zero carbon emissions by 2070 and reducing 1 billion tonnes of carbon emissions by 2030 aligns with the ambitious Amrit Kaal: Vision @ 2047.” He also announced that the Government of India has extended the PLI scheme by another year to enable the auto industry reap benefits of the incentives being provided for manufacturing advanced automotive technologies.

During the session, Vinod Aggarwal, President of SIAM and Managing Director & CEO of Volvo Eicher Commercial Vehicles Ltd., underscored the imperative need for sustainable mobility to secure a better tomorrow. He mentioned, “Over the past two years, we’ve witnessed remarkable growth, with the industry’s current size standing at INR 12.46 lakh crores, including exports worth INR 3 lakh crores.” He highlighted the six pillars of sustainability on which the auto industry and SIAM is presently focussing with close association with Government of India viz. Javik Pahal (biofuel), Vidyutikaran (electrification), Gas Gatisheelta (gaseous fuels), Harit Hydrogen (Green Hydrogen), Chakriyata (Recycling) and finally Surakshit Safar (Safe Journey). He also mentioned the progress undertaken by the industry to increase its localisation content.

Shailesh Chandra, Vice President of SIAM and Managing Director of Tata Motors Passenger Vehicles Ltd. and Tata Passenger Electric Mobility Ltd., said, “The Government’s commitment to the Amrit Kal vision 2027, along with the imperative to achieve net-zero emissions, sets the stage for a forward-looking India. We are witnessing a remarkable transition towards electric vehicles (EVs), aligning our industry with global benchmarks. SIAM has embarked on a proactive journey, with a strong focus on biofuels and a future centered around green energies. SIAM’s commitment not only resonates with India’s environmental goals but also underscores our dedication to saving lives on the road. Our collective commitment to sustainability is the path toward a safer, more holistic future that lies ahead for the country.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The interface between the EPLAN Platform and the 3DEXPERIENCE platform of Dassault Systèmes will systematically be expanded by both parties working together.

EPLAN and Dassaults Systèmes entered into a technology partnership as part of the EPLAN Partner Network on the first day of the Hannover Messe. Both parties will be working on expanding the interface between EPLAN and the Dassault Systèmes 3DEXPERIENCE platform. The goal is seamless integration of electrical engineering and fluid-power technology in the context of product development. Dassault Systèmes Managing Director Eurocentral Dominic Kurtaz and EPLAN & Cideon CEO Sebastian Seitz signed the agreement in Hanover, Germany. The partners will beneficially be contributing their expertise in the interests of their shared clients, thereby enabling companies to set up end-to-end digital development processes.

Aiming for higher process efficiencies

Sebastian Seitz explains: “With the bidirectional interface between the EPLAN Platform and the Dassault Systèmes 3DEXPERIENCE platform, we’re increasing the process efficiencies of our common clients. When all systems are bidirectionally connected – ECAD, ERP and PDM, for instance – users are workly in a truly interdisciplinary manner and thus much more efficiently.”

“With this partnership, we support our joint customers in achieving new dimensions of efficiency and productivity when it comes to holistic product development based on the creation and capitalization of virtual twins,” adds Dominic Kurtaz, Managing Director EURCENTRAL, Dassault Systèmes. “The bidirectional interface simplifies numerous processes and creates new collaboration opportunities for our customers. We are therefore delighted to take this groundbreaking step together with EPLAN.”

The partnership will be expanded in the coming months. Both companies are working in tandem to further optimise the interface – the PLM 3DEXPERIENCE Connector – and provide new solutions for digital product development in the cloud environment. A joint demonstration environment is also planned as part of the Engineering Collaboration Network (www.ecn-online.com) with videos and sample data in the PLM cloud environment, as well as joint interaction on customer projects.

Bidirectional coupling of engineering and PLM

The interaction of EPLAN and the 3DEXPERIENCE platform allows that the data management processes for electrical engineering and fluid-power engineering can be automatically controlled. What’s special about it is that access to the Dassault Systèmes cloud-based platform is available directly in EPLAN Electric P8 and EPLAN Fluid. For instance, components lists and bills of materials can be synchronised with just one click. For users of both platforms, automating routine processes makes everyday work even easier – common operations such as searching for, finding and creating projects, checking in or out of them, or exporting EPLAN project pages into neutral formats are all carried out much more efficiently with the interface. Fast and easy document generation in particular will save users both time and effort, since all that is needed to output in neutral formats is a checkmark when checking in. The neutral formats are then automatically linked to the associated EPLAN project.

EPLAN and the 3DEXPERIENCE platform have bidirectional communication. Checking into projects from EPLAN on the platform is automated, as is opening projects from the PLM system. Important descriptive PDM attributes, including information for the drawing header (as an example), can be added companywide in the 3DEXPERIENCE platform and are automatically available during the next checkout of the EPLAN project. Furthermore, the software supports traditional PDM functionality such as the approval or transfer of documentation to manufacturing.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

IoT-enabled data analysis technology to improve energy efficiency, pre-empt maintenance, and increase uptime of compressed air systems.

Elgi Equipments Limited introduced Air~Alert, an IoT-based Air Compressor Monitoring System, for the Indian market. After a successful launch at the Hannover Messe in Germany earlier this year, the ELGi Air~Alert smart 24/7 remote monitoring and alert system is now available to ELGi’s customers in India for new and existing installations*.

Air~Alert is a data transmission and analysis service that monitors critical parameters and sends out actionable insights and alerts to users. With these insights, customers can improve uptime and maximise efficiency with smart monitoring and data related to air compressor performance. The service also enables customers to act in time and avoid potential failures. Additionally, Air~Alert enables 24/7 remote monitoring of the air compressor. It delivers trend graphs and information about operating parameters, including discharge pressure, oil temperature, variable frequency drive (VFD) speed (where fitted), total running hours, trips, and alerts on a live online interface accessible remotely from anywhere in the world.

Air~Alert also notifies customers and ELGi channel partners about scheduled maintenance and fault occurrences while predicting commonly occurring failures. Monthly summary reports on overall health and operating parameters, including upcoming service requirements and preventative maintenance based on the data obtained, are sent to customers.

The operational and performance data from the compressors are acquired by Air~Alert from the compressor controller, transmitted in an encrypted form, and sent to secure and dedicated Air~Alert servers in the cloud. Smart algorithms then work on the data to enable intelligent prediction with actionable alerts, reports, and trends – which are returned securely to the operators as easy-to-read actionable dashboards.

Throughout the process, the data is structured and analysed to provide smart analysis that helps users to plan maintenance activities, enabling energy efficiency improvements with the compressor. The Air~Alert failure prediction modulealso predicts if the compressor is likely to fail in the future. At the end of the process, data is translated into comprehensible alerts and reports that allow the user to take timely action.

With ELGi’s Air~Alert, users can track highly informative utilisation trends providing actionable intelligence and take corrective actions, such as:

- Operating pressure band optimisation based on the utilisation rate

- Replacing an existing fixed speed unit with a variable speed VFD unit/ or adding a retrofit VFD

- Providing an energy efficient, lower size compressor in case of very low utilisation rate

- Detecting leaks based on an unexpected change to a higher utilisation rate over time

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

In the evolving landscape of Industry 4.0, the symbiotic relationship between cables and connectivity has assumed importance, forming the cornerstone of automation and laying the foundation for seamless network communication within India’s wire and cable sector. Gary Bateman, MD, LAPP India, says as India forges ahead on its digital transformation and technological integration, the pivotal role of cable and connectivity solutions has risen to prominence.

In the dynamic domain of Industry 4.0, the intricate link between cables and connectivity has gained immense significance, serving as the bedrock of automation and forming the core of seamless network communication in India’s wire and cable sector. As India advances toward digital transformation and heightened technological fusion, the unpretentious yet crucial role of cable and connectivity solutions has emerged as the driving force behind this evolutionary journey. In the tapestry of India’s technological advancement, the fusion of cables and connectivity stands out as the vital element that binds the efficiency of automation with the expansive reach of network connectivity, propelling the nation towards an innovative and interconnected future. Utilising fixed monitoring devices like LAPP’s ETHERLINE® GUARD, which continuously oversees Ethernet cables, enhances plant availability through proactive maintenance.

Amid the ever-evolving landscape of industrial interconnection and automation, LAPP India’s ETHERLINE® GUARD distinguishes itself as an innovative solution, reshaping the idea of monitoring data cables. Operating as a compact yet potent tool, the ETHERLINE GUARD takes the lead in preventive and predictive maintenance approaches, offering a transformative alternative to reactive methods. Traditional maintenance practices often followed a reactive pattern, only addressing issues after they had escalated into disruptions or failures. However, this method has proven costly and disruptive, resulting in downtimes, production losses, and higher repair expenses.

The innovation of the ETHERLINE GUARD lies in its ability to break free from this reactive cycle by continuously monitoring data cables, spotting anomalies, fluctuations, or potential failures in real-time. Outfitted with advanced sensors, it watches critical factors like temperature, humidity, and vibration along the length of data cables. Through sophisticated algorithms and data analysis, the device detects patterns and deviations that might indicate imminent problems. This foresight empowers maintenance teams to intervene proactively, scheduling corrective measures during planned downtimes, thus sidestepping the disruptive aftermath of unforeseen breakdowns.

By scrutinising historical and real-time data, the ETHERLINE® GUARD anticipates potential cable failures and declining performance, enabling maintenance squads to take proactive steps. Its adaptability to various data cable types makes it versatile and suitable for various applications and industries. Deployable across numerous data cable installations, the device is scalable to meet the demands of diverse industrial setups. In line with the tenets of Industry 4.0, it delivers real-time data insights and predictive capabilities that contribute to industries’ digital transformation. In essence, the functions and characteristics of the ETHERLINE® GUARD converge to furnish a comprehensive solution that empowers industries to shift from reactive maintenance strategies to proactive and predictive approaches. By ensuring the well-being and reliability of data cables it plays a pivotal role in optimising operational efficiency, curbing costs, and elevating overall productivity in industrial settings.

This cutting-edge data cable monitoring device is specially designed for Ethernet-based networks in automation technology. Its core function oversees the lifespan of data cables prone to failure, especially in critical applications such as dynamic environments. It’s ideally suited for data cables adhering to the 100BASE-TX transmission standard (up to 100 Mbit/s) as defined by IEEE 802.3, thus making it compatible with a wide array of Ethernet protocols, including EtherCAT, EtherNET/IP, and 2-pair PROFINET applications. Engineered for usage within control cabinets, this versatile device boasts an IP 20 protection rating, ensuring dependable performance even in demanding industrial conditions. The ETHERLINE® GUARD provides:

- A holistic solution for preemptive maintenance.

- Guaranteeing the endurance and uninterrupted functionality of essential data cables in automation systems.

- Ultimately contributing to enhanced operational efficiency and decreased downtime.

In India’s industrial landscape, where sectors like manufacturing, energy, and transportation are rapidly embracing digitalisation and automation, the role of the ETHERLINE® GUARD becomes particularly impactful. It empowers these sectors to retain their competitive edge by harnessing technological advantages while safeguarding the reliability and resilience of their data cable networks.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Over the past two years, the Industrial Products and manufacturing sector has seen a maximum increase of 20 percent in adopting AI/ML solutions.

After the COVID-19 pandemic, Indian businesses have embraced advanced analytics and data-centred choices. The PwC report, titled “Towards a More Intelligent Future: Influence of AI in the post-Covid period”, reveals that the industrial products and manufacturing domain has experienced the highest integration of AI/ML in the past couple of years. Nearly 64 percent of surveyed entities in this sector indicate they are presently in the initial phases of their AI-driven evolution, reflecting the potential for additional investments and growth driven by AI/ML solutions within this industry.

PwC conducted surveys that included more than 220 CXOs and decision-makers in the Indian market, building upon a prior investigation conducted in 2020. Simultaneously, PwC executed the 2022 AI Business Survey, extracting insights from 1,000 worldwide business and technology leaders accountable for their companies’ AI strategies.

While there has been a significant rise in the implementation of AI with considerable and favourable outcomes, current trends suggest that the travel and hospitality sector has reached a point of saturation, says the report. In contrast, the Technology, Media, Telecom, Healthcare, and Pharmaceutical industries have made consistent advancements; yet they face certain challenges in assessing ROI, particularly pre- and post-Covid-19 times.

Compared to these sectors, the retail and consumer market has experienced reduced AI integration, attributed to challenges in pinpointing viable use cases amidst shifting market dynamics and consumer actions.

Sudipta Ghosh, Partner & Leader – Data & Analytics, PwC India, said, “As organisations mature in their journey towards using AI for driving business outcomes, a three-pronged approach around identification of appropriate use cases, the rigour of measuring and communicating the RoI along with driving adoption and scale at the enterprise level using the framework of responsible and explainable AI will be critical.”

Dr. Indranil Mitra, Managing Director & Leader of Advanced Analytics, PwC India, said, “As the volume of enterprise data grows, it is becoming increasingly important to leverage this data in a meaningful way. Companies using AI to model this data are reaping the benefits of business transformation enabled by effective decision-making. However, to truly differentiate themselves from the competition, leaders must also deeply understand the risks around security, privacy, and accountability.”

Sector-wise AI adoption trends

· Industrial Products & Manufacturing: Between mid-2020 and 2022-23, the sector experienced the highest growth of 20 percent in adopting AI/ML solutions. After implementing these solutions within 12 to 18 months of the pandemic, entities in this field garnered the most advantages from AI in three key business areas: manufacturing and operational processes, supply chain and logistical operations, and information technology and cyber security.

● Retail: Compared with the other sectors, the retail and consumer industry witnessed a marginal decrease of 6 percent in 2022–23 compared to 2020. This was triggered by the gap in identifying the right use cases and measuring the RoI. Use cases in this sector are primarily in sales and marketing, customer service, and supply chain and logistics, with 68 percent, 52 percent and 56 percent of participants reporting only marginal to no improvements.

● Technology, Media & Telecom: As per the survey, there is a nearly 15 percent increase in respondents deploying enterprise-wide AI/ML solutions at scale. To keep up with market forces and build a long-term competitive advantage, organisations are piloting AI/ML solutions to investigate and measure their impact. There was an almost 7 percent increase in such implementation at the pilot level in 2022-23 compared to 2020.

● Healthcare & Pharmaceuticals: In the wake of the Covid pandemic, this sector has seen steady progress in AI adoption, demonstrating a 7 percent growth since 2020-21. According to the survey, 85 percent of participants are interested in AI-powered solutions prioritising patients, such as personalised treatment strategies for autonomous disease identification and support in prevention and cure. Additionally, around 65 percent are open to and willing to pay for services that utilise AI to predict illnesses or medical issues. However, only 15 percent of all respondents fully trust AI-generated diagnostic outcomes, while 78 percent of the population intends to delve deeper by consulting doctors and discussing these results.

Finally, in contrast to 2020, the Travel & Hospitality market is heading towards saturation. The industry has witnessed a roughly 7 percent increase in the adoption of AI. Nearly 99 percent of the surveyed organisations have integrated AI/ML extensively, at least in specific domains. These businesses have also observed a corresponding enhancement in operational performance, with 67 percent of respondents indicating a substantial enhancement in outcomes due to targeted investments in certain business functions.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

According to this article, the training phase serves as an opportune moment to introduce students to novel paths for embarking on their careers, ones that align with environmentally conscious and sustainable practices.

Why do we need to train welders?

Welding stands as a specialized profession demanding skilled labour across the globe. Be it in construction, manufacturing, automotive, shipbuilding, aerospace, oil & gas, railways, or even small roadside grill factories, the requirement for welders is evident. While various statistics indicate a mismatch between the demand and supply of welders, the reality is more nuanced. Developing and less developed countries in Asia, Africa, and Eastern Europe, including our own, produce a substantial number of welders annually. However, the emphasis is on highly skilled welders who can seamlessly adapt to diverse roles.

Additional factors contributing to the soaring demand for skilled labour include certain countries’ immigration policies, retirements, and attrition. Despite welding’s transformation into a field encompassing science, technology, and art, some welders may opt for jobs within air-conditioned shopping malls or as food delivery personnel. Thus, the question arises: where can we source proficient welders? This is where the significance of continuous training becomes evident, ensuring a consistent supply of adept professionals.

Green welding, the need of the hour

Our global environment is continuously being polluted due to the various activities of civilized individuals worldwide. These activities span from significant industries and manufacturing units to vehicles, encompassing even welding practices. Industries are undertaking diverse measures to diminish pollution, including installing electrostatic precipitators, exhaust gas treatment, chemical neutralization, afforestation, evaluation of environmental impacts, and subsequent actions. However, the concern remains regarding welding’s environmental impact, which deserves individual consideration.

While contemporary welding processes, coupled with advanced alloys, electrodes, and filler wires, represent improvements over past technologies, many of these processes still contribute to climate pollution and pose risks to the workforce. This is where the concept of “Green Welding” emerges. It necessitates the adoption of technologies that generate minimal pollution, such as friction stir welding, magnetic pulse welding, diffusion welding, and even submerged arc welding. However, integrating these processes proves challenging and unfeasible, particularly in construction projects where welding is a substantial component. Such construction-related welding also entails the training of welders.

Cost of training

The primary expenses associated with welder training encompass materials, electrodes, filler wires, gases, power usage, essential tools, fire safety gear, and the presence of a skilled instructor. Effective welding training entails comprehensive instruction and practical experience, necessitating a substantial consumption of materials and consumables. Unfortunately, a side effect of this process is the emission of fumes and gases that contribute to pollution.

A green way of welding training

Here comes the requirement for Welding Training via Augmented Reality becomes evident. Initiating the shift towards environmentally friendly welding processes commences with training welders utilizing virtual and augmented reality. This approach curtails training expenses by supplying virtual tools and materials while eradicating the ecological effects of real welding. The training phase serves as an opportune moment to introduce students to new paths for embarking on their careers that align with environmentally conscious and sustainable practices. Employing welding simulators for training eliminates material expenses, consumable costs, and environmental pollution.

Augmented Reality Welding Training Simulator

These welding simulators replicate the most realistic welding experience without actual welding. Students engage with 3D-coded objects, immersing themselves in the sensation of genuine welding with authentic sounds and seam tracking facilitated by real welding torches. Computer-generated imagery lends a hands-on impression, while sensors within helmets feed data for image generation and storage. This stored data aids students in identifying and rectifying errors. Seam tracking assists them in maintaining steadiness in their hand movements, facilitating wrist manoeuvres during real welding tasks. This entire process can be projected on a secondary screen, enabling fellow students and instructors to observe and assess performance. Moreover, this simulation approach can be employed for various joint types and welding processes like SMAW, GMAW, FCAW, or GTAW.

The Reality

Augmented reality training programs have found application in numerous training institutes across diverse disciplines. Rather than replacing traditional welding training, these programs serve as supplements, providing instant feedback to students to enhance their future performances. This approach is a significant step towards contributing to environmental preservation on a larger scale. Although the initial setup costs might be considerable for training institutes in developing countries, the long-term benefits are promising, including cost savings and reduced training expenditures. The resultant reduction in training costs will enable underprivileged students to participate in welding training programs, ultimately bridging the global gap between the demand and supply of skilled welders.

Expertise shared by- Rituraj Bose, PMP, Quality Management Consultant, Honorary Secretary General, The Indian Institute of Welding.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Steinbacher Dämmstoff GmbH in Austria has installed a new packaging line for PU insulation panels. A RoRoStretchPack solution has replaced two packaging lines for packaging multiple panel sizes. Improved 6-sided packaging and automation are the headlines behind installing the new packaging line.

Steinbacher searched for a fresh solution for packaging their PU insulation panels for some time. The primary reason is the need to enhance packaging quality. The Production Manager at Steinbacher in Erpfendorf, Markus Brandstätter, emphasised, “Securing waterproof packaging is a top priority for us. Our end-customers often store the panels outdoors at construction sites, and due to high demand, we can’t always store the panels indoors before shipping.” Markus elaborated, “Our previous packaging approach lacked waterproofing, which led to the potential issue of water getting trapped between the panels when stored outside.”

Previously, the standard-sized PU panels (1200×600 mm) were packed with a sleeve to create four-sided packaging for a bundle of panels. These bundles were then arranged on a pallet and wrapped using stretch wrap film. The larger panels were earlier packaged utilising heat shrink, but consistent problems emerged with the weldings. Consequently, neither of these packaging methods ensured complete waterproofing.

Six-sided packaging – sealed and waterproof

Markus Brandstätter says, “A few years ago, we came across RoRoStretchPack® produced by Tentoma”. RoRoStretchPack® is a horizontal packaging solution employing a tubular stretch hood film covering all six sides. Achieving sealed and waterproof packaging only requires welding the two ends of the film. Both packaging and sealing steps are integrated into a single process. This innovation was developed by Tentoma in Denmark, inspired by the established vertical stretch hood packaging technique commonly utilised for five-sided pallet packaging.

Markus explains,” After the initial assessment, we sent different sizes of product samples to Tentoma for test packaging. When the packaging samples returned to Austria, they were thoroughly tested regarding packaging quality, environmental impact, and logistics. We also investigated consumables, potential savings, and automation to evaluate the business case”.

Energy savings

Maximum energy efficiency and cost savings to improve sustainability are focus areas for Steinbacher. Markus Brandstätter says,” Previously 20-30 percent of the packaging used heat shrink. This is now replaced by RoRoStretchPack® packaging. By directly comparing our previous packaging solution and RoRoStretchPack® packaging, we have reduced energy consumption by about 50 percent on the packaging line”.

Film consumption is also an important parameter of both cost and sustainability. Steinbacher is monitoring the film consumption per pallet. Even though Steinbacher has gone from 4-sided to 6-sided packaging, they have reduced film per pallet by using RoRoStretchPack®. Markus adds, “Now that we have become familiar with the new packaging line, we will optimise the process to further film reductions.”

A structured project process

Markus Brandstätter states, “Summarising the project process went very well from the first contact till installation and commissioning. It was a structured process with good communication with Tentoma. We had fixed monthly meetings and later fixed weekly meetings when the FAT (Factory Acceptance Test) approached. Both the FAT and the installation were well planned and executed.”

In connection with the installation, Tentoma trained three employees from Steinbacher as key users on the new packaging line. He concludes, “Our employees felt confident with the new packaging line after the introduction. We are satisfied with the capacity and the packaging quality of the new RoRoStretchPack® packaging solution.”

Benefits for Steinbacher Dämmstoff GmbH

· 6-sided packaging and waterproofness

· Improved and uniform satisfied quality

· Removed heat shrink from the packaging

· 50% energy savings on the packaging line

· Automation and reduced number of processes in the packaging line.

View of Steinbacher’s new inline RoRoStretchPack® packaging line.

· The film stand (FS) contains up to 12 km of film, which reduces the number of film shifts.

· The film unit (FU) welds the front end of the tubular film to create a hood.

· The gripper unit (GU) stretches and moves the film to the packaging lane. The film is rolled off the GU while the panels are packed.

· The back sealing unit (BU) seals the 6-sided packaging.

· The in-feed conveyor receives the panels directly from the production line.

· The output conveyor transports the packed panels to a labelling machine and a palletising system.

Production manager, Mr Markus Brandstätter: ”We are satisfied with the capacity and the packaging quality of the new RoRoStretchPack® packaging solution”.

For more information, visit: www.tentoma.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Veolia Water Technologies & Solutions has revolutionised the South Asian dairy industry’s water management approach. The company has successfully conserved precious groundwater resources while prioritising environmental sustainability by deploying an MBR-based wastewater treatment plant and a zero-liquid discharge (ZLD) system.

A prominent dairy company in South India emerges as the first dairy player by becoming the first in its industry to recycle 100 percent water, utilising Veolia Water Technologies & Solutions’ MBR technology and Zero Liquid Discharge system at its Mega Plant. This fastest-growing private dairy enterprise has embraced sustainability initiatives, implementing Veolia’s membrane bioreactor (MBR) technology, a High Recovery Wastewater treatment plant, and a Power Driven (MVR) Zero Liquid Discharge system at its Erode-based Mega Plant.

Originating as a premium paneer brand in Tamil Nadu and the southern regions of India, this company has evolved into the sole dairy in the country to convert all procured milk into an array of value-added products, boasting more than 150 stock-keeping units (SKUs) spanning 20 categories. Today, the brand is synonymous with quality dairy products like Curd, Fresh Paneer (cottage cheese), Mozzarella Cheese, Cheddar Cheese, Processed Cheese, and Gouda Cheese, apart from other value-added products like cream, butter, ghee, ice cream, curd and other dairy-based Indian sweets.

Over the past four years, it commissioned a wastewater treatment plant with a capacity of 600,000 litres per day and a 60,000 litres per day Zero Liquid Discharge (ZLD) plant in collaboration with Veolia Water Technologies & Solutions. This dairy firm has played a crucial role in sustaining the local environment and community. Approximately 600,000 litres of river water have been saved from being discharged into the local groundwater, safeguarding the livelihoods of nearby villagers. Moreover, by employing the MBR Wastewater Recycle Plant, freshwater consumption has been curtailed, indirectly benefiting around 10,000 households in the Erode region with uninterrupted access to clean water.

Prioritising sustainability

The decision to adopt Veolia Water Technologies & Solutions’ MBR technology was largely driven by the dairy company’s commitment to sustainability. It is opting for Veolia’s MVR technology for the Zero Liquid Discharge system, which uses power instead of conventional steam evaporators. This aligns with the company’s endeavour to minimise its carbon footprint and reduce the use of fossil fuels.

Gopal Madabhushi, Senior Vice President, Veolia WTS, South Asia, said, “Unlike its peers that recycle roughly 30 -40 percent of wastewater and discharge the rest of it into the adjoining ecosystem, the customer has prioritised sustainability. This meant bearing an additional burden over and above the project cost. The customer has continued to consider such costs as an investment into sustainability. It further selected Veolia WTS for treating an additional 1.2 MLD ( 12,00,000 litres per day) of wastewater, wherein approx. 10,00,000 litres per day of water will be recycled and reused for utility operation. The plant is expected to be commissioned by the end of the year.”

In its groundwater resource assessment of 34 units in the Erode district of Tamil Nadu, the Central Ground Water Board (CGWB) categorised 11 as over-exploited and semi-critical. At the same time, two were considered critical, with the rest found safe. Amid such critical water levels, this enterprise has embarked on a mission to conserve this precious resource.

In conjunction with its corporate social responsibility (CSR) efforts, the company has installed a 30 KW Solar Power Plant, ensuring continuous water supply to local homes and agricultural fields. The power grid is connected to the Tamil Nadu Generation and Distribution Corporation (TANGENCO). As an indirect benefit, water will be supplied uninterrupted, as there will be no power cut-off. Home and agricultural fields will receive water continuously. This will benefit nearly 10,000 villagers in Tudapathi Panchayat District. A separate Solar Power Plant is commissioned to cater for the entire manufacturing facility, making it a 100 percent Green power/ Energy company.

On-the-go learning and innovation

This initiative has also spurred innovation within the company, underscoring its commitment to adopting cutting-edge technologies throughout its value chain. This commitment is evident in the decision to recycle 100 percent of its wastewater through Veolia’s Zero Liquid Discharge (ZLD) plant.

Looking ahead, sustainability remains paramount as the company plans to expand its operations. By partnering with Veolia Water Technologies & Solutions, this dairy leader sets an example for other industry players to tackle water challenges with sustainable technological solutions to avoid the discharge of treated water in the surrounding ecosystem. In a way, it is prioritising long-term environmental goals over short-term costs.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The objective behind ABB India securing a contract with Reliance Life Sciences to implement automation and control solutions in their biosimilars and plasma proteins manufacturing plants in Nashik, Maharashtra is to achieve operational excellence throughout the manufacturing processes.

ABB India has secured a significant automation contract from Reliance Life Sciences (RLS) to automate their newly established manufacturing plants in Nashik, Maharashtra. RLS’s sprawling 160-acre facility in Nashik will be home to manufacturing units producing plasma proteins, biopharmaceuticals, oncology pharmaceuticals, and vaccines.

Managing large-scale biotechnology production presents intricate challenges in terms of processes and automation. These processes strictly adhere to regulatory guidelines to ensure the quality of products. ABB’s System 800xA® solution reduces manufacturing errors and ensures high-quality yields. This solution seamlessly interfaces with different skid systems and is extensively employed for smooth operator interaction, batch control, and production information on the factory floor.

G. Balaji, Senior Vice President and Head of Energy Industries at ABB India highlighted ABB’s strong positioning in the pharma and life sciences sector, emphasising the potential for growth and innovation. As India solidifies its position as a biopharmaceutical manufacturing hub, ABB India is well-prepared to capitalise on the automation-driven industrial revolution in these sectors, pivotal for maintaining large-scale production with assured quality.

K.V. Subramaniam, President of Reliance Life Sciences, noted the company’s tradition of leveraging automation technologies for quality and productivity enhancement in its manufacturing processes. The collaboration with ABB represents continuity in this approach and advancement in virtualisation and process control.

ABB’s System 800xA solution

System 800xA will be installed in a virtualised environment for RLS. This move offers cost and operational benefits by simplifying server management and reducing the IT footprint, subsequently lowering operational costs. ABB’s multichannel remote I/O solutions will facilitate efficient data communication, reduce wiring complexity, optimise hardware space utilisation in the plant, and expedite project execution. Given the pharmaceutical nature of the manufacturing unit, the DCS (Distributed Control System) will adhere to US FDA 21 CFR Part 11 standards.

The latest Windows Server 2022 platform will provide the DCS, ensuring extended lifecycle support and top-notch software management. This approach avoids plant shutdowns for software upgrades, decreasing overall costs associated with downtime, software/hardware updates, and related services. The integration offered by System 800xA brings together various plant components, eliminating the need for multiple PLCs. This integration guarantees a unified audit trail, integrated data reports, and streamlined operations, reducing maintenance requirements, training needs, and inventory complexities. Additionally, it simplifies third-party audits. Alongside the DCS, RLS will adopt ABB’s modular remote I/O solution, which offers flexibility and a plug-and-play concept for automation. This approach enables quicker commissioning and process implementation, with the added benefit of scalability for future capacity expansion.

As Reliance Life Sciences expands its manufacturing capabilities, they intend to produce high-quality biosimilars at an affordable cost. With the largest number of biosimilars in India and a global development pipeline, the company’s expansion aligns with its goal to become a major player in the biopharmaceutical industry.

ABB has a track record of delivering advanced DCS solutions to prominent pharma companies in India and has been recognised as the world’s leading DCS provider for 23 consecutive years, according to the ARC Advisory Group’s 2021 report.

For more details, visit: go.abb/process automation

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

India’s space achievements, from Chandrayaan-3’s historic moon landing to ISRO’s pioneering efforts, underscore the nation’s growing prowess in space technology, manufacturing and the promising future of private sector involvement.

As an Indian, one of the proudest moments in terms of technological achievements is undoubtedly our success in space exploration. The tremendous interest and enthusiasm it has generated across the nation, second only to cricket, is truly remarkable and bodes well for the entire country. Space endeavours are incredibly challenging, and the sheer number of technologies involved in missions like Chandrayaan-3 is staggering. Our success in these intricate technologies showcases our capabilities as a nation.

In a historic achievement, India has become the fourth nation to successfully land on the moon, securing its place as the first to touch down on its elusive southern pole. The Chandrayaan-3 mission promises to unveil the mysteries of this uncharted lunar region.

Amit Shah, the Minister of Home Affairs, highlighted the impressive strides made in the last decade under the new space policy. India’s record-breaking accomplishments include launching 55 spacecraft, 50 launch vehicle missions, simultaneous deployment of 104 satellites, a successful first attempt at reaching Mars, and now, triumph with Chandrayaan-3.

Crucially, reforms in the space sector in 2020 have paved the way for private sector involvement, promising to accelerate India’s space missions. The Union Home Minister emphasised that this new space endeavour elevates India as a global launch pad for space projects. It opens space exploration opportunities for Indian companies and holds the potential to create numerous job opportunities for the nation’s youth.

Jamshyd Godrej, Chairman and Managing Director, Godrej & Boyce, added, “We extend our heartfelt congratulations to ISRO for successfully landing Chandrayaan-3 on the lunar surface. This achievement is a testament to India’s remarkable advancements in space exploration and technology. We will be the fourth nation worldwide to attain this milestone and pioneers in demonstrating a soft landing on the moon’s south pole. We celebrate this moment enthusiastically and look forward to continued contributions to the nation’s scientific excellence and progress journey. This success reinforces our belief in the power of indigenous manufacturing and our contribution to pushing the boundaries of technological innovation.”

Space resilience and manufacturing expertise

Jagdeep Dhankhar, the Vice President, noted that Vikram’s soft landing has solidified India’s presence in the 21st century. The approved cost for Chandrayaan-3 stands at Rs. 250 Crores, excluding the launch vehicle expense. Chandrayaan-2 achieved an impressive 98 percent success rate, fulfilling most of its mission goals, despite minor issues during the Lander Module’s last phase, which resulted in higher velocities at touchdown. Drawing from this experience, ISRO meticulously planned Chandrayaan-3 to ensure a flawless touchdown at the moon’s south pole.

What’s even more significant is that this success reaffirms that India possesses the knowledge and the determination to excel in these fields. It’s a testament to the people’s expertise and their unwavering commitment, even in the face of past failures. The resilience demonstrated in revisiting and refining a mission that faltered four years ago is commendable. Manufacturing in the space sector demands meticulous precision, unwavering reliability, and the highest reproducibility standards. Aerospace and defence sectors share these critical requirements, emphasising the need for precision manufacturing and unmatched reliability.

In space and defence, history is filled with instances where even minor manufacturing or operational errors have resulted in costly failures. Manufacturing, therefore, holds a pivotal role. Equally crucial is the pursuit of next-generation technologies. Chandrayaan’s success illustrates India’s persistent pursuit of space technology since the 1960s. The loss of a space mission affects the country and represents a significant loss of technology and knowledge for the world. Failures are integral to learning, especially in aerospace, where the stakes are exceptionally high. Once something ventures into space, it faces the unforgiving nature of the cosmos, where help or intervention is impossible. It is essential to recognise that in these strategic sectors, the technologies we employ have not just single but multifaceted uses across various fields of engineering and science. This versatility adds another layer of significance to our achievements.

MSME

Union Minister for Micro, Small, and Medium Enterprises, Shri Narayan Rane, extended congratulations to the nation and ISRO for Chandrayaan-3’s successful landing. He emphasised that the MSME Ministry played a significant role in realising the mission alongside the country’s scientists.

Shri Rane noted that the Bhubaneswar Tool Room, an MSME Ministry entity, manufactured approximately 54,000 aerospace components of 437 different types for the mission. Additionally, IDEMI Mumbai, another institute under the Ministry, contributed to parts manufacturing for Chandrayaan-3. The Union Minister highlighted that the mission’s success will bring benefits not only to India but also to the global community.

ISRO

ISRO, as an organisation, has truly excelled in mastering the domain of systems engineering from end to end. This is a capability that needs to be improved in our country. While the IT revolution swept us up, ISRO concentrated on building comprehensive engineering systems expertise. What sets them apart is their work culture. Shinto Joseph, Director – South East Asia Operations, LDRA Technology, added, “Throughout my career, I’ve closely collaborated with ISRO, and I’ve noticed they prioritise placing their most influential individuals in quality and reliability roles.

In contrast, in many other Indian organisations, such roles are often seen as punitive assignments. ISRO’s approach empowers these experts to overrule decisions when necessary, ensuring that quality is paramount. This commitment to getting it right from the beginning is a practice that ultimately pays off in the long term.”

In the business realm, scalability in manufacturing is a constant topic of discussion. India, as a late entrant in lower-end manufacturing, faces certain disadvantages. However, the scenario shifts in high-tech manufacturing, where trust plays a pivotal role. India is better positioned in the global supply chain, gaining trust and credibility as a reliable vendor. This is a facet we can leverage by focusing more on high-tech manufacturing. While low-tech manufacturing remains essential, mastering high-tech manufacturing is an area where we can excel. Mr. Puneet Dalmia, the Managing Director of Dalmia Bharat Limited, congratulated ISRO, adding, “Chandrayaan3 captures the grit and determination of India: No dream is too far when fueled by passion. Celebrating ISRO, celebrating India. This is India’s moonshot decade.”

In the context of ISRO, a significant shift is on the horizon. Soon, regular rocket launches and reusable technologies will likely transition to private entities. ISRO will focus more on core research and development. This transition opens up substantial opportunities for the private sector. While many private companies already collaborate with ISRO, new entrants are emerging, creating a dynamic space sector. Although this shift may take time, the lessons learned from the defence industry’s evolution will be transformative for space. The move from a government-centric approach to a more private-public model within India and global collaboration is being tested and marks a maturation phase. We are learning and adapting and headed in the right direction. ISRO’s initiatives to involve the private sector in special missions are pivotal in allowing them to excel and contribute significantly to the space sector’s growth.

Chandrayaan-3’s Objectives

Prime Minister Modi expressed his confidence that the Chandrayaan Maha Abhiyan’s achievements will propel India’s exploration beyond lunar orbits, pushing the boundaries of our solar system and tapping into the limitless potential of the universe for humanity. He underscored India’s commitment to ambitious future goals, revealing ISRO’s plans to launch the ‘Aditya L-1’ mission for an in-depth study of the Sun and its aspirations regarding Venus.

Following its successful landing, Chandrayaan-3 is set to deploy a rover on the moon’s surface to explore the lunar south pole. The rover’s tasks include leaving an imprint of the Indian flag and ISRO logo on the lunar regolith as it moves and collecting data on the moon’s surface composition.

The rover will also be equipped with instruments to gather information on the moon’s atmosphere and return this data to the lander. Meanwhile, the lander will measure near-surface plasma density, study the thermal properties of the lunar surface, assess seismic activity, and investigate the structure of the lunar crust and mantle. This comprehensive research is expected to take approximately two weeks to complete.

India’s space achievements, exemplified by Chandrayaan-3’s success, showcase its tech prowess. With private sector involvement and precision manufacturing, India’s space journey advances. Future goals include Sun and Venus missions, solidifying its global presence. Chandrayaan-3’s lunar exploration and research exemplify India’s innovation and exploration spirit.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Ideal for smaller job shops using ageing lathes, the threaded lathe sleeves enable coolant flow and high-speed drilling capabilities in the manufacturing industry.

Wohlhaupter India Pvt. Ltd. offers expert engineering, technical support, and onsite application services within India for Wohlhaupter GmbH and Allied Machine and Engineering Corp. The leading manufacturer produces hole-making and finishing tooling systems for the manufacturing industry in India. The company introduced threaded lathe sleeves as a stocked-standard solution to allow coolant flow to newer style holders without rear pipe taps. This innovation is particularly beneficial for smaller job shops using older lathes that lack through-turret coolant capabilities.

Allied Machine aims to make advanced cutting tool technologies accessible to ageing machines previously unable to handle high-speed drilling. To achieve this, customers in the general machining industry can directly connect an external coolant line to the back of the sleeve using standard ½ NPT or ½ BSP pipe fittings. This feature lets users connect external high-pressure pumps directly to a turret station, maximizing pressure and flow for drilling long and deep holes.

As the manufacturing industry pushes for faster drilling solutions, drill bodies have evolved with additional coolant inlets and outlets, leading to a decline in the traditional rear pipe tap method of inducing coolant. Despite these innovations, Allied Machine recognizes the importance of not alienating businesses built around reliable machinery. The launch of threaded lathe sleeves is part of Allied’s ongoing commitment to bringing small and large machine shops into the new era of drilling technology.

John Weniger, product manager, explains, “At the same time, with continued innovation comes the risk of alienating those who have built their businesses centred around machinery that has stood the test of time. Because of this, the launch of the threaded lathe sleeves is “just another example of Allied’s continued effort to bring machine shops, small and large, into the new age of drilling.”

For more details about the threaded lathe sleeves, visit: https://www.alliedmachine.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Rohit Saboo, President & CEO of National Engineering Industries, deliberating sustainability, states that businesses and governments increasingly show interest in EVs, with e-commerce companies adopting e-Mobility for eco-friendly last-mile deliveries to reduce carbon emissions.

What latest advancements will make India the third-largest automotive industry globally by 2030?

By 2030, India aims to become the world’s third-largest player in the automobile industry. It is currently the fifth-largest market, and by 2030, it wants to be all-electric. The nation’s ambitious plan involves transitioning entirely to electric vehicles (EVs) by that year. This shift is driven by several key factors: reducing reliance on foreign oil imports, curbing pollution, and fulfilling international commitments related to climate change.

To facilitate the growth of the Indian EV industry, the country is making substantial investments. These investments include establishing a new production centre and developing an enhanced charging infrastructure. The government has introduced the Production Linked Incentive (PLI) scheme to promote domestic production of EVs, hydrogen fuel vehicles, and local ACC battery storage products. In 2021, India saw the sale of more than 300,000 EVs nationwide.

In the fiscal year 2023, the automotive sector’s capital expenditure (capex) is expected to exceed $3 billion, equivalent to Rs 27,000 crore, showing an impressive year-over-year growth rate of 24 percent. Key drivers of this expansion include accessible auto financing, transparent financing options, and the increasing popularity of electric vehicles.

In addition to these factors, here are some burgeoning trends expected to shape the Indian automotive sector in 2023:

Rapid Growth in Autonomous Vehicle R&D: Investments in research and development for autonomous vehicles have significantly increased. Recent technological advancements have opened up new opportunities for automakers to explore autonomous vehicles to enhance the commuting experience, and this trend is expected to gain traction in 2023.

Leveraging 5G Technology: Cars typically have around 100 million codes and 30,000 parts, and recent technological advances have expanded those numbers even more to aid drivers in navigation. The introduction of 5G technology is poised to be a game-changer, allowing wireless communication of crucial information such as traffic updates, weather conditions, and road conditions while on the road.

The Internet of Things (IoT) in Connected Cars: IoT forms the foundation for connected cars, which offer enhanced safety, comfort, and on-demand services. These advanced modes of transportation can collect and share data, enabling services like digital data sharing, remote diagnostics, vehicle health reports, data-only telematics, 4G LTE Wi-Fi hotspots, turn-by-turn directions, and proactive measures to prevent breakdowns.

Increasing Emphasis on Electric Vehicles: Growing awareness of climate change issues drives interest in electric vehicles. In 2023, the sale of EVs is expected to surge, with the highest selling year in 2022 reaching 429,217 units, marking a remarkable 218 percent increase from the 134,821 units sold in 2021. This reflects a broader national commitment to reducing carbon footprint and achieving sustainable development goals.

How are I 4.0 technologies practised for sustainability in the automobile industry?

During the recently concluded COP27 summit, global leaders unveiled an ambitious objective for our planet: to attain net-zero emissions by 2070. The automotive sector plays a crucial role in helping achieve this goal.

Industries are adopting sustainable practices and integrating innovative technologies within their supply chains to work towards zero emissions. Central to enhancing these supply chains’ sustainability are the principles of a circular economy and end-to-end visibility from start to finish.

Following are the trends that can be witnessed:

Original equipment manufacturers (OEMs) increasingly seek greater transparency across their supply chain to monitor and improve sustainability. This transparency is essential to ensure every component is produced with the utmost sustainability. Through comprehensive traceability and visibility of components, the carbon footprint of each part can be accurately determined. This allows OEMs to prioritise purchasing components from vendors with the lowest carbon footprints whenever possible.

Another approach OEMs adopt to enhance sustainability involves reimagining the assembly line, a longstanding cornerstone of the automotive industry. For many decades, cars have been predominantly manufactured on assembly lines, boosting production efficiency and generating significant waste and energy consumption. As a response, several OEMs are revisiting manufacturing methods used before the invention of assembly lines. Modular manufacturing represents the opposite of an assembly line and is being utilised as a more sustainable alternative.

A growing number of executives joining automotive companies are enthusiastic about integrating sustainability into various aspects of their business operations. Consequently, internal organisational dynamics serve as a driving force behind sustainability efforts.

The automotive sector has compelling reasons to believe it can achieve its goal of becoming a net-zero emitter. Over the past 15 years alone, the industry has undergone remarkable advancements. Electric cars (EVs) have transformed in this comparatively short time from being on the fringe to becoming mainstream, highly desired automobiles used daily by millions of homes.

What macro factors and trends influence transitioning towards EV manufacturing and charging infrastructure?

India intends to become the global leader in the sale of electric vehicles. As a result, multiple big manufacturers and EV start-ups have invested much time and money into creating electric vehicles over the past five years. This surge in investment has resulted in a notable increase in adopting Battery Electric Vehicles (BEVs).

The Indian Electric Vehicle Market is poised for remarkable growth, with a projected Compound Annual Growth Rate (CAGR) of over 44%. It is expected to reach a market size of USD 47 billion by 2026, a substantial leap from its 2021 size of USD 5 billion.

The government has implemented various programs and regulations to promote the expansion of the EV industry. Incentives have been offered to consumers and manufacturers to stimulate the EV sector. Notably, businesses and governments are increasingly interested in EVs, with e-commerce companies adopting e-mobility for eco-friendly last-mile deliveries to reduce carbon emissions.

At NBC, we have already initiated developing and validating our bearings for electric vehicles (EVs), featuring sensor-integrated bearings (SIB) designed in-house. These bearings offer superior attributes to standard ones, including higher rpm capability, reduced noise and friction, increased power density, and extended lifespan. We have already supplied these bearings to some EV Original Equipment Manufacturers (OEMs) in the 2W, 3W, and passenger car segments, and we are collaborating with major OEMs in the commercial vehicle sector. Our research and development team also works closely with OEMs to create custom-bearing solutions to meet their specific requirements. We are working closely with domestic and international OEMs to provide them with optimised bearing solutions for their upcoming vehicles, ensuring they are well-prepared for the future.

What role does FAME II play in promoting production capacity and electric vehicle manufacture?

The Faster Adoption and Manufacturing of Electric Vehicles in India (FAME II) scheme is vital in promoting the production capacity and manufacture of electric vehicles (EVs) in India. Launched by the Indian government in 2019, FAME II aims to accelerate the adoption of EVs and create a robust manufacturing ecosystem for electric mobility in the country. Out of total monetary support, about 86 percent of the fund has been allocated to create demand for EVs in the country.

FAME II is an effort towards boosting domestic production capacity for electric vehicles and components. The scheme encourages domestic manufacturers to invest in EV production facilities and develop advanced technologies, thereby creating job opportunities and promoting the growth of the EV industry in India. The scheme also promotes local manufacturing of EV components, including batteries, motors, and power electronics, to reduce import dependency and strengthen the domestic supply chain.

What opportunities do you see for software and technology providers for the electrical mobility automobile sector?

These are fascinating times for software and technology providers, with the electrical mobility sector seeing a boom. With the rising adoption of electric vehicles (EVs), there is a corresponding increase in the demand for charging infrastructure solutions. Software providers can work towards developing smart charging solutions, mobile applications for charging station locating and monitoring, etc.

What latest innovations are happening in the automobile industry with robotics and 3D printing implementation?

Modern technologies like artificial intelligence (AI) and robotic automation are viewed as a significant advantage for the automotive sector. These innovations are crucial in fleet management, enhancing driver safety, and optimising vehicle inspection and insurance services. Additionally, 3D printing offers multiple benefits to the automotive industry, including accelerating design and testing through rapid prototyping using 3D-printed models. Furthermore, it empowers manufacturers to produce customised spare parts according to their needs.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

According to Sanjeev Arora, President, Motion Business, ABB India, the primary focus remains centered on sustainability and reliability encouraging the widespread adoption of high-energy-efficient motors and variable speed drives.

Please discuss ways to improve the performance and energy efficiency of electrical motor solutions.

Advanced technology is imperative for the global shift towards sustainability in electric motion. As the global embrace of electric technologies continues, there is a projected twofold increase in the demand for energy-efficient motion solutions by 2040.

There has been a consistent improvement in the effectiveness and capabilities of electric motors. Some of the key factors that have enabled and will continue to enable further advancements include the availability of superior materials, improvements in manufacturing techniques, the utilisation of Multiphysics computational tools, and the growing trend of using Variable Frequency Drives (VFDs) for variable-speed applications, particularly those involving centrifugal loads.

To illustrate, approximately 45 percent of the electricity generated worldwide is transformed into motion by electrical motors. In India, there exists a substantial installed base of motors with low efficiency, referred to as IE1. To foster growth and enhance performance, it is imperative to transition to at least IE3 as the minimum efficiency standard. It is also essential to educate customers about the long-term benefits of cutting-edge technologies that offer efficiency levels of IE5 or more, even if they require a higher upfront investment.

Please talk about ABB Motion’s business activities, specifically focusing on motors, drives, and related areas.

Our pioneering products, including drives, motors, generators, and comprehensive integrated digital powertrain solutions, are leading the way towards a low-carbon future across a variety of industries, cities, infrastructure, and transportation sectors.

Our primary focus is on energy efficiency, sustainability, and reliability. We provide IE5 efficiency synchronous reluctance motors and ultra-low harmonic drives, which effectively limit current harmonics to less than 3 percent. ABB’s Motion Business area delivers a wide range of products, including low and high voltage motors, generators, variable frequency drives, PLCs, traction motors, converters, batteries, and battery chargers. Additionally, we offer complete package solutions that incorporate these products seamlessly.

Our Service division goes beyond commissioning and post-sales support for our products. We assist customers in their digital transformation journey, particularly in areas such as predictive maintenance, energy assessment, and optimising the operations of industrial power and drive systems through our digital offerings.

What recent advancements are made in power transmission and integrated digital powertrain solutions?

Through digital powertrain, we monitor the health of variable frequency drives, motors, and the driven equipment. The analytics and dashboard help in predictive maintenance, avoiding unplanned down times while increasing the availability and OEE.