Inovance Technology India has unveiled a new 900 sq ft. branch office in Hyderabad, increasing the industrial automation specialist’s reach in India, and providing enhanced local service and support.

The latest branch is Inovance Technology’s 5th office in India, joining its existing network of offices in Mumbai, New Delhi, Ahmedabad and Hyderabad, and its Chennai headquarters.

A total of five members of staff are now based in the Hyderabad office, in its sales and technical departments, increasing overall productivity and output from the existing team in Hyderabad.

The inauguration event to mark the opening of the new Hyderabad office was attended by a host of Inovance Technology India executives and members of the sales, technical and marketing teams.

Attending the opening of the new office, Inovance Technology India Director, Anil Kumar, says, “Inovance Technology India is committed to providing high quality, innovative products, alongside the best levels of customer service and support. We are delighted to be opening a new office in the vibrant city of Hyderabad, increasing our presence in the region and delivering even more efficient local service and support.”

Inovance Technology India’s Head of Business Development Christopher Thiagarajan added, “We are looking forward to enjoying even greater success with this new branch office, and will continue to seek out new opportunities to expand our footprint in India in order to provide our market-leading, high performance automation solutions to more customers.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The N-Tron® Series NT5000 Gigabit Managed Layer 2 Ethernet switches have been voted the winner in the Automation & Controls category.

Red Lion, manufacturer of innovative technologies empowering industrial organisations to access, connect, and visualise their data, were recognised among the best by the 2023 IDEA Awards for N-Tron® Series NT5000 Gigabit Managed Layer 2 Ethernet switches. Votes placed by the engineering community recognised Red Lion as a Winner in the Automation & Controls category.

The NT5000’s innovative and intuitive graphical user interface includes a logical view showing active ports, power supply, temperature and contact relay status of the switch and color-coded gauges for port traffic and events to allow administrators to quickly identify and address possible network disruptions in real-time, helping lower total cost of ownership.

Red Lion President, Marcel van Helten noted, “We are honored to receive the Machine Design IDEA award for our N-Tron® Series NT5000 industrial Ethernet switch. This award is a validation of our ongoing commitment to delivering technology which enables our industrial customers to improve the efficiency and security of their OT network infrastructure.

The 2023 IDEA Awards celebrates outstanding innovation in product design and function for the engineering industry. Every year, it showcases and rewards companies who have contributed to the advancement of technology through their creative, innovative, and impactful designs. IDEA Award winners are chosen by qualified readers of Machine Design, Electronic Design, Power & Motion, Microwaves & RF, and Vision Systems Design.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Radix announces new midstream digital engineering services team to showcase Hybrid Intelligent Solutions in Partnership with AVEVA and its entire portfolio.

Radix, a global technology solutions company announces a new Midstream Digital Engineering Services Team that expands its partnership with AVEVA and its entire diversified portfolio of services and clients. The partnership bolsters Radix’s ability to turn data into increased profitability, with hybrid intelligence that enables midstream companies to reduce costs, optimize asset reliability, and deliver efficiency in regulatory standards, such as Environment, Health, and Safety (EHS).

Radix has an unparalleled understanding of the midstream business models utilizing AVEVA’s entire portfolio supporting digital transformation initiatives with global Midstream Oil and Gas customers. Leveraging industry domain expertise, Radix collaborates closely with stakeholders to reduce costs and generate new revenue. The accelerated partnership focuses on taking the strategic assets of Midstream O&G operating data, leveraging edge-to-cloud scalabilities, and producing better data-driven decisions.

Radix is a member of the AVEVA System Integrator Partner Program and is also a platinum sponsor at this year’s AVEVA World in San Francisco. The Radix team in attendance comprises of industry experts and data scientists, recognized as subject matter experts by Pipeline and Midstream Owner Operators, and viewed as the best-in-class by global customers in the industry.

Exhibiting in Booth #1 at the Moscone Center, Radix will demonstrate their expertise on hybrid intelligence in a Partner Solutions Track, participate in a keynote panel focused on Digitalization and Sustainability, and share how to prevent unexpected equipment shutdowns with digital twin results. In addition, the team will present customer success cases with a deep dive on enterprise operational data infrastructures and analytics utilizing AVEVA’s entire portfolio.

Bry Dillon, Senior Vice President of Partner Sales at AVEVA, said: “AVEVA’s partnerships with global, industry-leading organizations help our mutual customers leverage the power of technology to become more agile, resilient, and sustainable. Together, we solve complex industrial challenges where the strengths of more than one company are needed.

“Industries are looking for both integration and transparency. Integration of dispersed, diverse data sets on their business operations into a single, open, neutral digital backbone. And transparency through insight, which is provided by trusted applications and seamless digital experience. This gives them the confidence to make decisions quickly and based on data-driven intelligence. We’re delighted that Radix is a platinum sponsor at this year’s AVEVA World in San Francisco in October. We look forward to welcoming them at our flagship industrial software event.”

With more than 1,600 team members, Radix has grown by 60% in the past two years, adding new offices in Europe and Asia. Maintaining its growth trajectory, Radix’s major equity partner is Sotreq, one of Caterpillar Inc.’s largest dealers in the world.

With digital innovation teams embedded inside Fortune 500 customer organizations, and in close collaboration with Tom Richardson, US Central and Southeast Vice President at AVEVA, Radix continues to showcase its unique ability to add unparalleled value in any software platform and for any sized customer in need of immediate transformational business value.

Natalia Klafke, Global Head of Energy & Sustainability, Radix states, “More than engineers, Radix collaborates with the best in class to revolutionize data for the industries we serve into profitability for our customers. They see huge transformational business value through our extensive suite of optimization capabilities – turning insightful data into increased profitability while helping them reach their sustainability goals.”

The Radix team presence will be a highlight of the event, allowing customers to engage and discover new pathways to learn more about how Radix is converting insightful, raw data into actionable operational business intelligence.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The Society of Indian Automobile Manufacturers (SIAM) organized the ‘Green Plate EV Rally’ in New Delhi to promote electric vehicles and sustainability, featuring over 100 electric vehicles.

The Society of Indian Automobile Manufacturers (SIAM), the apex body representing India’s prominent automobile manufacturers, hosted the ‘Green Plate EV Rally’ at Pragati Maidan, New Delhi. In partnership with the Ministry of Heavy Industries, Government of India, this event marks a significant stride in promoting eco-friendly transportation and underscores SIAM’s unwavering commitment to driving the widespread adoption of electric vehicles across the nation.

In the presence of the Chief Guest, Dr. Mahendra Nath Pandey, Union Minister of Heavy Industries, Government of India, the “Green Plate EV Rally” was ceremoniously flagged off. The rally showcased an impressive fleet of over 100 electric vehicles, including 2-wheelers, 3-wheelers, cars, and buses. Its central aim was to raise awareness and enhance customer confidence in electric vehicles and to exhibit the capabilities of the Indian automotive industry, which has developed and launched multiple electric vehicles to meet the needs of Indian consumers over the past couple of years.

Kamran Rizvi, Secretary, Ministry of Heavy Industries, Government of India; Dr. Hanif Qureshi, Joint Secretary, Ministry of Heavy Industries, Government of India; Vinod Aggarwal, President of SIAM and Managing Director & CEO of Volvo Eicher Commercial Vehicles Ltd; Sushant Naik, Chairman, SIAM Electric Mobility Group and Global Head – Government and Public Affairs, Tata Motors Limited; Suman Mishra, Co-Chairman, SIAM Electric Mobility Group and MD & CEO, Mahindra Last Mile Mobility; Vipin Surana, Co – Chairman, SIAM Electric Mobility Group and Vice President, Volvo Eicher Commercial Vehicles Limited, and Rajesh Menon, Director General, Society of Indian Automobile Manufacturers (SIAM) were present during the ceremony.

SIAM also felicitated Priyanka Pilaniya, Vice-Captain of the Indian Women’s Kabaddi Team for winning gold medal at the 19th Asian Games 2023 held in Hangzhou, China at the event.

In his address, Dr. Mahendra Nath Pandey, Union Minister of Heavy Industries, Government of India, said, “The Indian Government has provided constant support for the growth of EVs in the country. We can proudly say that 9.4 lakh EVs are now on Indian roads. The outcomes of the PLI scheme in battery development and supporting domestic manufacturing are reducing our dependence on others, and making us self-reliant. In the coming period, India will become a major battery manufacturing hub. We have also found lithium deposits in Jammu and Kashmir, and the government is making efforts to make India competitive in every field without delay. EVs have grown from 0.13% in 2019-20 to 4.3% now, and SIAM has made significant contributions in leading this change. I extend my congratulations to the team. We must work together to achieve our sustainability objectives and promote the green mobility movement.”

In his address, Kamran Rizvi, Secretary, Ministry of Heavy Industries, Government of India, said, “There is a saying that change is the only constant. Positive changes have made our lives more convenient, and electric vehicles are one of them. Issues like safety, cost, and others have acted as barriers, but over time, these issues have been addressed, and EVs are now widely accepted. The Indian automobile industry has supported and facilitated this positive change. EV manufacturing is a technical endeavor, and the ministry has supported the industry with FAME and PLI schemes. We expect 12 lakh scooters to be sold this year, which means the public is actively adopting EVs, and we have a long road ahead. By 2030, we anticipate having 60-70% of electric two-wheelers and, in a few years, 70-75% of electric three-wheelers. For cars, we aim to sell one lakh cars and double that number. SIAM leadership has worked closely with the government, and as a result, we have been able to initiate many successful endeavors for sustainable mobility.”

On this occasion, Vinod Aggarwal, President of SIAM and Managing Director & CEO of Volvo Eicher Commercial Vehicles Ltd., said, “Over the last couple of years, the Indian automobile industry has made significant progress towards sustainability to meet the decarbonization targets set by the Indian government. The country has made rapid strides, supported by proactive actions. India’s transition to e-mobility is well underway, and as the economy continues to grow, electric vehicle adoption will also increase. Strong support is needed in terms of policy and infrastructure. Under our विद्युतीकरण (Electrification) initiative, SIAM remains dedicated to address industry’s issues in close collaboration with all stakeholders across the value chain.”

Dr. Hanif Qureshi, Joint Secretary, Ministry of Heavy Industries, Government of India, said, “The rally is a great initiative to spread awareness on EVs which is key to meet electrification goals. I extend my thanks to SIAM for taking up such initiatives. The Government has supported electric vehicles adoption and the industry has to play its part and make efforts along with the government. At present, Europe, the US, and China have more EV sales, and India has to come on par with them.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

OMRON’s current range of mobile robots features distinctive control technology, facilitating secure and seamless transportation that can be effortlessly integrated into production facilities. This advanced technology ensures enhanced efficiency through integrated control systems.

Recently, manufacturing facilities have gained significant importance in improving productivity quality and creating worker-friendly environments that alleviate the strain of repetitive tasks. There is a growing need to enhance the efficiency of operations involving the repetitive transport of heavy materials, work-in-progress items, and finished products through automation, all aimed at reducing the physical toll on employees. For instance, in the automotive industry, the move toward high-mix, low-volume production systems requires the distribution of materials to various locations, resulting in a higher frequency of transferring small batches of work-in-progress items increasing the physical demands placed on workers.

OMRON, a prominent player in factory automation and Industry 4.0 solutions, has introduced the MD-650 autonomous mobile robot (AMR) to enhance efficiency in production facilities. By introducing this medium-payload (650 kg) mobile robot, OMRON has broadened its range of autonomous robots, catering to a broader range of needs for part and material transportation. OMRON’s existing lineup of mobile robots ranges from 60 to 1500 kg, and the MD-650 provides a mid-weight range option (650 kg). Its unique control technology enables safe and smooth transport that can be easily implemented at production sites where people and machines work in the same area.

According to Sameer Gandhi, MD, OMRON Automation, India, “Matching the pace and needs of the industry for high-speed pick & place, and human collaborative robotics solutions, OMRON Automation Business in India is expanding its diversified Robotics portfolio. This new addition to our AMR family is to strengthen & enhance the solution for warehousing (pallet transfer to warehouse), line side replenishment, and aid flexible manufacturing, thus generating value for our customers to make hassle-free & automated material movement. It relieves operators from manual tasks for transferring material while ensuring the safety of human beings working in the same space.

We look forward to collaborating with the right solution partners to co-create & develop advanced industrial solutions based on the human-machine collaborative technology the robot offers.”

However, even if the optimal robot for each process is selected, controlling a large fleet of mobile robots requires different management systems and methods for each robot model. This requires investment in each system and management to ensure the smooth transportation of various heavy objects.

The unique “OMRON Fleet Manager” software enables integrated control of up to 100 mobile robots on a single system, eliminating the need for multiple fleet management systems, and automatically selects the optimal mobile robot for each process based on payload and availability. OMRON aims to add another model with a medium payload range of up to 900 kg shortly to strengthen the product lineup further.

Features:

• High speed and safety with top-level transfer speed*² in the medium payload range*¹ and unique obstacle avoidance algorithm.

OMORN MD-650 has proven experience based on implementing several thousand units at manufacturing sites worldwide. The new system operates smoothly even in narrow aisles due to its maximum speed of 2.2 m/sec, advanced navigation functions, and obstacle avoidance algorithms. In addition, introducing advanced battery and charging technology enables 8 hours of operation on a 30-minute charge.

• Integrated control of all mobile robots using proprietary software technology

A single system can provide integrated transfer routes for 100 mobile robots with different payloads and control the transfer sequence in real-time. The advanced linkage within a single system enables real-time routing, even for inter-process transfers at different production speeds, to achieve efficient transfers with minimal retention.

• High level of safety by ISO369: international safety standard*³.

It is designed for compliance with ISO 3691-4 (enacted in 2020), the latest safety standard for industrial Automated Guided Vehicles (AGVs).

OMRON continues to expand its existing product lineup to contribute to the creation of safe factory environments and robots to help reduce the burden of material transport processes across various industries. Further developments to its proprietary software control will promote safe and optimised transport paths at sites across industries. The company’s vision is to develop solutions that maximise the value of people and create a prosperous future for people, industry, and the earth.

To learn more, please visit: www.omron-ap.co.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The N-Tron® Series NT5000 Gigabit switches, with a durable metal enclosure and wide temperature range is a compact solution for reliable operation in harsh, industrial environments.

The NT5000 switches and their gigabit speed are designed to improve network security and reliability. They maximise operating performance and system uptime through seamless integration and offer advanced management and diagnostic capabilities, network redundancy, and layered security. The N-Tron® Series NT5000 switches are available in 6, 8, 10, 16 and 18 port configurations in all copper or a mix of copper and fibre options that can meet specific installation requirements. With a durable metal enclosure and wide temperature range, the NT5000 is a compact solution for reliable operation in harsh industrial environments. Configuring switches can be a confusing and time-consuming process. The NT5000 is engineered for fast and easy deployment right out of the box. Its modern, graphical user interface includes a configuration wizard that walks users through the initial setup. Today’s cybersecurity threats can result in severe consequences. The NT5000 features password encryption, multilevel user access and MAC security, IEEE 802.1X with RADIUS remote authentication and more.

NT5000 features:

Graphical dashboards, N-RingTM auto-member, Port mirroring, Cable diagnostics, STP/RSTP/MSTP, IGMP v1/v2/v3, SNMP v1/v2/v3, NTP, LLDP and LACP, Fast boot, allowing traffic to pass in less than 20 seconds, Wide shock and vibration tolerance, Extensive compliance certifications, including product safety (UL/CUL) Ordinary and Hazardous locations, Emissions/Immunity: FCC/ICES/CE, ATEX/IECEx, Marine: ABS, Rail: EN 50155, EN 50121, EN 61373, UKCA.

Administrators can view the event and Syslog to see the state of the network in real-time and receive notifications about access attempts or configuration changes. The switch can be set to disable user or port credentials after failed access attempts automatically.

To know more, visit redlion.net/nt5000

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The new igus energy chain made entirely of recyclate can be installed in seconds and guides cables reliably.

Cost-effectiveness extends beyond just groceries; it’s equally applicable to energy chains. Often, the most straightforward products come at a lower price and embody cutting-edge technology. igus has developed the Snapchain 2.0, especially for low-stress and flat cable packages. The energy supply system consists of just one side link, to which cables can be fixed with cable tie-wraps. It is made entirely of recyclate, making it a sustainable solution.

More space is often needed to ensure a reliable energy supply to cables in cash registers and drawer systems, office furniture, and even gaming machines. To address this challenge, igus introduced the Snapchain 20 years ago. It consists of one side link to which cables are attached and guided with a defined bend radius. This design allows it to fit into the tightest of spaces and has proven its effectiveness in thousands of applications worldwide. Now, igus has enhanced the snapchain. “We would like to give our customers even more flexibility in chain harnessing. This is why we changed the design so that the cables can now be easily fixed with standard cable ties,” explains Kira Weller, Product Manager for e-chains at igus. The cable tie wrap is inserted into the side link, routed around the cable package and closed. Another notable feature of the snapchain 2.0 is that its standard version is made of the igumid CG recycling material.

From old to new

The igumid CG material comes entirely from recycled energy chains. As part of the Chainge program, igus has been taking back used energy chains, regardless of manufacturer, since 2019. The material is then sorted according to type, cleaned and returned to new quality in a single process. The material then becomes igumid CG, which has been used successfully in the E2.1 cradle-chain energy chain series since the spring of 2022. Numerous test series in the 3,800-square-metre in-house laboratory at the igus location in Cologne have confirmed its tensile force and breaking moment. The e-chains from recycled material contribute to resource conservation, promoting the circular economy. According to the Environment Product Declaration, this sustainable raw material cycle reduces CO2 by 28%. “The snapchain 2.0 is a cost-effective all-around package. It provides our customers with a product that is reliable, sustainable and quick to assemble. It is the second chain series, the standard version we make from recycled material. At the end of its life, it can also be entirely recycled,” says Weller.

Find out more at: https://www.igus.eu/info/snapchain-2-0

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Schuler’s latest innovation, Shopfloor Operations Management (SOM), is revolutionizing the way operators deal with equipment downtime. With real-time data extraction and precise reporting, it offers a game-changing solution for optimizing production processes.

During unforeseen periods of equipment downtime, it’s common for operators to be preoccupied with tasks other than meticulously documenting the exact cause in the shift log. However, this step holds paramount importance in averting recurrent incidents down the line. The most recent addition to Schuler’s Digital Suite, known as “Shopfloor Operations Management” (SOM), offers users a convenient solution. SOM automatically extracts pertinent data from the system controller and, in conjunction with other performance metrics, transforms it into a readily understandable format.

“SOM shows at a glance the current situation in production and reveals any potential problems early,” according to Product Manager Andreas Gebele. “The performance indicators can be compared with past shifts and orders to optimize processes in future.” The reporting provides an ideal basis for the daily shopfloor meeting: “An increase in the availability of a system by 30 percent is entirely realistic.”

Since SOM is directly integrated into the coordinating control, best possible data quality including precise time stamps is assured. Moreover, the accurate production data also ensure a more realistic cost calculation. Full connectivity to customer ERP/MES systems as well as open data interfaces to AI solutions are also guaranteed.

Via a user-friendly terminal for entering machine data, external causes of system downtimes – for example the forklift that delivers the blanks too late – can be quickly and easily recorded. Custom notes are supported, as well as addressing specific issues to the relevant responsible person using a ticketing system.

For more info, www.schulergroup.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

According to Manoj Nair, Power Generation Business Leader, Cummins India, CPCB IV+ compliant gensets in India herald a new era in emissions reduction. These eco-friendly generators slash PM and NOx emissions by 90 percent, offering superior performance and reduced environmental impact.

What are the primary objectives of the CPCB IV+ emission standards?

The CPCB IV+ emission norms mandated by the Ministry of Environment, Forest, and Climate Change are a part of the Indian government’s efforts to prevent, control, and abate air pollution across the country. These updated emission standards aim to simplify the regulatory framework by introducing a unified standard that applies to portable and stationary generators, regardless of their fuel type, with a capacity of up to 800 KW. This streamlines matters for manufacturers by reducing complexity. Furthermore, these standards usher in a technological transformation in the industry, advocating for adopting cleaner emissions technologies. Complying with the CPCB IV+ emission standards results in lower greenhouse gas (GHG) emissions and reduced fuel consumption by generators, aligning with our nation’s broader environmental objectives.

How is CPCB IV+ compliant gensets from Cummins India making a positive environmental impact?

The introduction of Cummins India’s CPCBIV+ compliant generators on July 5, 2023, marks a remarkable engineering achievement. These machines have evolved from basic mechanical devices into advanced electronic technologies incorporating intelligent control systems, advanced exhaust treatment mechanisms, remote monitoring, and predictive maintenance capabilities. This transformation has yielded a substantial 90 percent reduction in particulate matter (PM) and harmful nitrogen oxide (NOx) emissions from generator exhaust compared to the previous CPCB II standards. This achievement enables our customers to fulfill their diverse backup power requirements and empowers them to contribute to environmental sustainability. This strategic shift in our product range ensures our compliance with regulations. It aligns with our commitment to being a responsible organization dedicated to delivering innovative and environmentally conscious power generation solutions.

How does the closed-loop system with real-time monitoring enhance the performance of gensets?

The closed-loop system, equipped with real-time monitoring, greatly improves the efficiency and dependability of these generators. This system continually evaluates the generator’s operational performance and adherence to emission standards, guaranteeing that it remains within the ideal parameters. The system triggers an alert if any deviations occur, facilitating prompt corrective measures. Additionally, customers are notified of these alerts via SMS and email, allowing them to respond promptly to any irregularities. This minimizes downtime and ensures that the generators consistently operate at their highest performance levels, ultimately enhancing their longevity and lifespan.

Discuss the advanced after-treatment systems in gensets and their role in enhancing fuel efficiency.

The advanced after-treatment systems used in Cummins gensets are carefully designed to improve fuel efficiency and ensure adherence to stringent emission norms. These advanced systems consist of a combination of Diesel Oxidation Catalyst (DOC), Selective Catalytic Reduction (SCR), and Diesel Particulate Filter (DPF) / Partial Flow Filter (PFF) based on the engine architecture. They are either a single module or a combination of multiple modules, depending on the size and capacity of the after-treatment system.

These advancements ensure more efficient fuel combustion, improved pollutant control, and enhanced fuel efficiency.

What benefits do users experience from remote monitoring and control in genset operation?

Remote monitoring allows users to manage generator operations from any location, eliminating the necessity for physical presence. This improves efficiency and responsiveness. Moreover, the capability to quickly initiate and halt operations via remote control is a valuable asset, especially in urgent situations, guaranteeing the swift deployment of generators to fulfill power needs.

It also enables users to inspect the system’s status, detect faults, and promptly access essential notifications, lowering operational and maintenance expenses.

Please explain fuel and DEF sensors’ significance in ensuring optimal efficiency of gensets.

Fuel and Diesel Exhaust Fluid (DEF) sensors ensure peak efficiency. Fuel sensors monitor real-time diesel consumption, allowing immediate corrective measures if excessive fuel is used. Beyond performance improvements, they cut operational costs and emissions, contributing to environmental sustainability.

Furthermore, Diesel Exhaust Fluid (DEF) sensors ensure compliance with emissions standards by precisely controlling the injection of DEF, which reduces harmful nitrogen oxide emissions. Together, these sensors significantly boost generator efficiency, lower operational costs, and help meet rigorous environmental regulations.

How do you employ innovation and advanced digital tools to address environmental challenges and climate change?

Cummins is deeply committed to innovation and creating a positive environmental footprint. Our core values include promoting clean air and water, prosperous communities, and a healthier planet. Our mission is to enhance people’s lives by powering a more prosperous world, and we actively seek solutions to mitigate the effects of climate change.

Leveraging our rich legacy of over six decades in India and more than a century of global experience, we are confident in our ability to leverage advanced digital tools, adhere to strict emission standards, and tailor our products to meet the specific demands of the market and our customers. Our CPCBIV+-compliant generators exemplify this dedication, offering clean and efficient power solutions that cater to our customers’ evolving requirements while remaining committed to environmental sustainability.

What advantages do these gensets offer in emissions compliance?

CPCB IV+ compliant generators bring significant advantages regarding emissions adherence and reduced environmental impact. The primary benefit of these generators lies in their eco-friendliness, as they effectively slash particulate matter (PM) and harmful nitrogen oxide (NOx) emissions from generator exhaust by an impressive 90%. Moreover, these generators do not require the addition of any retrofit devices or dual fuel kits throughout their product lifecycle to manage emissions in the field, thus reducing the total cost of ownership. Integrating advanced engine technologies and after-treatment systems enhances system durability, providing superior performance, improved fuel efficiency, and equipment reliability.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Birla Carbon successfully acquired Nanocyl SA, a leader in multi-wall carbon nanotubes (MWCNTs), expanding its presence in the Energy Systems market and conductive applications.

Birla Carbon, one of the leading manufacturers and suppliers of high-quality carbon solutions, completed the acquisition of Nanocyl SA, a worldwide leader in multi-wall carbon nanotubes (MWCNTs’) based in Sambreville, Belgium. The acquisition expands Birla Carbon’s presence in the Energy Systems market, creating a leadership position in material critical to Lithium Ion battery performance along with other conductive applications.

Speaking about the acquisition, Dr. Santrupt Misra, Group Director, Birla Carbon; Director, Chemicals & Director, Group H.R., Aditya Birla Group, said, “Birla Carbon has been nurturing a number of innovation opportunities in its effort to realize its multi-prong sustainability agenda. The acquisition of Nanocyl is a clear step towards executing its strategy in that direction. We hope that this partnership will enable Birla Carbon to be a significant player in the emerging energy systems space. He further added, “Aditya Birla Group has been concentrating on investing in sustainability and circularity-driven initiatives led by innovation in order to be future-ready. The same is in line with our Purpose: to enrich lives by building dynamic and responsible Businesses that “inspire” trust.”

Sharing his thoughts on the acquisition, John Loudermilk, President and Chief Executive Officer, Birla Carbon, said, “We are thrilled to welcome Nanocyl into the Birla Carbon family. Laurent and his experienced team have been pioneers in the field of carbon nanotubes that provide unique performance characteristics for a wide range of applications, most notably energy systems such as lithium-ion batteries.” He further shared, “Birla Carbon’s commitment to driving growth through innovation in sustainability aligns well with the potential for MWCNTs to enable the electrification of the transportation industry, deliver enormous environmental benefits, and prevent climate change. We are committed to partnering with our growing family of customers to create unprecedented value with the expanded carbon portfolio of products and technologies.”

Laurent Kosbach, Chief Executive Officer, Nanocyl, stated, “We are proud of our journey to develop and commercialize MWCNT’s successfully over the past 20 years as an entrepreneurial start-up, with the support of our current partners and investors. However, with growing needs for our products, the time has come to join a Global industry leader in order to maximize the synergies and the potential of these materials across many end uses.” Mr. Kosbach continues, “Birla Carbon’s R&D expertise, portfolio of products, and market experience will enable Nanocyl and our products to reach their full growth potential”

Along with the Conductex™ family of conductive carbon black additives and active anode materials, the inclusion of Nanocyl’s advanced MWCNTs provides Birla Carbon with a remarkable range of solutions for conductive applications.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Large-scale manufacturing facilities in remote areas often rely on independent power generation sources to deliver the vast amounts of energy needed for operations. Turbo generators are often the cornerstones of these power sources. However, if they suffer unforeseen downtime, this reliance can result in a 100% loss of production. This was the situation faced by an Indonesian cement producer, which turned to Sulzer to resolve the failure quickly and upgrade its generator to protect uptime.

Ground to an unscheduled stoppage

The breakdown of the 55 MW generator was caused by strand-to-strand faults that eventuated into a stator connection phase ground fault. Due to the excessive amount of winding oil contamination from a leaking bearing labyrinth seal, the ground fault flash resulted in a stator fire. As this was the only power source for the facility, production was immediately halted, risking the delivery of orders to customers. Any order obligations would need to be met by other facilities, placing stress on the cement producer’s regional operations. To resolve this, root cause analysis and a rapid temporary repair was requested by the cement plant management, followed by a full stator rewind at a more convenient time to suit their production commitments

A thorough investigative inspection by Sulzer’s experts revealed that the failure was attributed to the stator winding design having parallel stranding, which caused high circulating currents. The tracking across the surface of the stranding resulted in excessive winding temperature, eventually instigating the ground connection phase fault.

Rapidly responding to an urgent repair

Due to a proven track record supporting the customer’s various production facilities, Sulzer was awarded the repair and upgrade project by direct appointment for the scope of winding and incorporating a 360° Roebel bar. A leading independent service provider for rotating equipment, Sulzer is a global expert in generator repairs and upgrades for steam and gas turbines with a local presence in Indonesia.

The technical proposal of utilizing 360° Roebel bars presented by Sulzer’s global technical team convinced the cement plant management that it was the most optimal solution, along with timeline assurance. Furthermore, the customer was aware of Sulzer’s robust global supply chain, which would expedite the project and support the generator long into the future. Compounding these advantages, Sulzer could offer a lead time of 10 weeks, while other vendors were still offering parallel strand conductors and completion schedules of several months.

To get the plant temporarily operational as soon as possible, Sulzer quickly completed a partial repair to the failed stator windings. This allowed the cement producer to work through their material stockpile and meet existing orders – which helped to reduce any loss of revenue caused by the generator failure. Illustrating its global engineering flexibility, Sulzer was the only vendor which could offer this partial repair – a testament to the company’s customer centricity.

A question of half-bar engineering and manufacturing

Meanwhile, Sulzer worked on re-designing the new stator windings. The 360° Roebel bars would eliminate future circulating current problems compared to the original designed parallel conductors. However, this required overcoming numerous engineering challenges due to the short length of the stator core

First of all, fitting the Roebel bars into the short stator core was going to take exceptional technical expertise. The OEM did not offer Roebel bars for this generator model, so Sulzer would be breaking new ground. Precision reverse engineering was required to ensure that the new top and bottom bars with a 360° Roebel would fit. Finally, the replacement bars would have to be engineered and manufactured specially for this generator. Thankfully, all these requirements were accomplished in-house by Sulzer’s experienced engineering and design team.

A generator upgrade uncoiled

Leveraging its global network, Sulzer Indonesia connected with the Birmingham Service Center in the UK, one of the numerous facilities within Sulzer which has the engineering and manufacturing facilities for high voltage stator coils and half bar production, backed by a comprehensive database and automated design capabilities. This overseas collaboration is common practice at Sulzer, with each facility in its network offering seamless access to the full global capabilities of the company.

Using data collected from the stator and existing top and bottom bars, the Birmingham Service Center reverse engineered the winding to incorporate a 360° Roebel. With this complete, engineers precision manufactured a half stator section to confirm the correct fit of winding pitch to expedite installation on-site. Sulzer produced 48 top bars and 48 bottom bars in 10 weeks – a lead time much shorter than the several months quoted by other service providers.

To ensure a continuous workflow and minimize the duration of the winding process, the bottom bars were shipped first, followed by the top bars. This phased delivery allowed the Sulzer Indonesia team to complete the generator rewind sooner, as waiting for a single shipment would’ve increased the project timeline by several days. Furthermore, this scheduling ensured that the project could be completed within a planned shutdown period of 10-12 weeks, reducing disturbance to their production operations.

A concrete foundation for reliability

The benefits of switching to Roebel bars were quickly apparent. Winding temperatures were greatly reduced, allowing the generator to be run more efficiently, providing energy cost savings to the cement plant. In terms of reliability, electrical circulating currents were all but eliminated, greatly reducing the risk of any future premature failures. Reduced winding temperatures also meant less thermal stresses on the winding insultation, improving service life. With the generator up and running, the pressure on the customer’s other facilities was alleviated too, with the plant now operating at full capacity.

When critical equipment suffers a breakdown, operations and production are always at risk. However, by trusting in the global expertise of Sulzer, this cement producer was able to avoid the worst-case scenario. The customer centric approach of Sulzer prioritized the needs of the cement producer, minimizing any impact to operations or business reputation. Beyond providing a stop-gap repair to keep production running, Sulzer employed its coil manufacturing and reverse engineering skills to build a new foundation for future generator reliability.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Socomec India has unveiled the MODULYS XM UPS, a groundbreaking medium-power model designed for longevity, reliability, and sustainability, offering scalability and seamless maintenance.

Socomec India has introduced the MODULYS XM UPS, which, with over 25 years of exceptional durability, represents a notable achievement in Socomec’s enduring dedication to innovation, quality, and sustainability.

Meenu Singhal, Regional Managing Director – Socomec Innovative Power Solutions said, “MODULYS XM, the new medium power model sets industry standards with 50 kW modules and scalable power up to 600 kW, within the same footprint. Boasting proven ultimate reliability, MODULYS XM features hot-swappable modules for seamless maintenance, adding modules in just 2 minutes. Socomec’s continuous investment in cutting-edge technology ensures unmatched UPS longevity, empowering our customers to meet sustainability goals and contribute to a greener future.”

MODULYS XM comprises a 50 KW power module and optimised set of fully equipped systems – MODULYS XM, for 250 kW + 50 kW redundancy and MODULYS XM, for 600 kW + 50 kW redundancy. MODULYS XM’s 50 kW power modules have proven reliability of more than 1,000,000 hours MTBF (Mean Time Between Failures), as certified by a third party based on robust data – which is at least 4 times longer than the best market standards.

In addition, both seismic resistance and double immunity to disturbances have been certified by a third party, against the highest market standards, with MODULYS XM demonstrating the highest degree of reliability.

Power modules are truly hot-swappable by on-site people and the whole process is simple and risk-free, taking just 2 minutes. This is possible thanks to self-aligning firmware, self-setting parameters and full self-testing – all of which are completely automatic and done without any human intervention. Static bypass and all other parts are also hot swappable via front access, while the UPS is working and without any interruption.

With a set of more than 25 standardised and pre-engineered parts, the MODULYS XM can be configured on customer needs in a multitude of combinations in order to create a tailor-made solution. Moreover, with hot-swap power modules, the system’s power can be increased on demand. On-site people can scale the system by adding a module, simply by plug-in it – without any risk. Furthermore, by adding an extra bypass module, it is also possible to increase the short-circuit current withstanding, making MODULYS XM unique in the market.

The design lifetime of MODULYS XM is in excess of 25 years in a Data Centre environment and in excess of 20 years in worst-case conditions, satisfying a key requirement of the circular economy, which is to keep products in circulation for longer. The lifetime has increased by 50% compared to market standards, and is proven beyond calculations and simulations, with MODULYS XM having passed demanding stress and accelerated lifetime tests.

Furthermore, the future availability of modules and all subassemblies is guaranteed for the complete lifetime of the UPS.

MODULYS XM is connected to the world, and to the world of its users. Socomec’s free mobile App, SoLive, automatically reports the latest status of the UPS, providing instant notification of any event. Alternatively, Socomec experts can provide 24/7 monitoring and will send a technician to location if necessary, or provide a notification for absolute peace of mind.

With remote troubleshooting technology, Socomec experts can connect to the UPS system, in order to run remote tests and diagnostics – all with zero transport-related carbon emissions.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The inaugural Machine Tool Connect Expo in Kolhapur, organised by IMTMA, saw significant success with strong industry participation, showcasing manufacturing solutions, and fostering regional collaboration.

The first edition of Machine Tool Connect Expo Kolhapur (MTX Connect Kolhapur 2023), organized by the Indian Machine Tool Manufacturers’ Association (IMTMA), on 8th and 9th October 2023 at the Pavillion Hotel in Kolhapur concluded successfully. Over 1300 visitors had registered for this event and nearly 900 visitors attended the two-day B2B expo.

MTX Connect Kolhapur 2023 was inaugurated by Mr. R.V. Gumaste, Managing Director, Kirloskar Ferrous Industries Ltd., Mr Nitin Despande, Chief Human Resources, Cooper Corporation, who was representing on behalf of Mr. Farrokh N. Cooper, Chairman & Managing Director, Cooper Corporation Pvt. Ltd. and Mr. Rajendra S. Rajamane, President, IMTMA also presided over the inauguration ceremony.

Speaking about the success of the expo, Mr. Rajendra S. Rajamane said that the first edition of Machine Tool Connect created a benchmark in the western region of India to address the manufacturing needs of industries in Tier 2 and Tier 3 cities. IMTMA wanted to take technologies closer to the industries and we have successfully done this through this show. Furthermore, it proved to be an important platform for the MSMEs in the region.

Prominent industry associations namely Gokul Shirgaon Mfrs association, Kolhapur Engineering Association, Kolhapur Chamber of Commerce and industries, Manufacturers Association of Kagal & Hatkanangale, Shiroli Mfrs Association, Indian Instt of Foundrymen- Kolhapur Chapter, Shri Laxmi Industries Association, Ichalkaranji Engineering Association and others from the regions had supported this event and extended their fullest active involvement in promoting this exhibition in a befitting manner.

Around 42 exhibitors from across the country presented their manufacturing solutions and established links to augment their business through this expo. Exhibitors showcased technologies in machine tools, digital manufacturing, laser technologies, tooling and metrology which are driving the manufacturing industry forward. Major visitors from wide spectrum of engineering industries came from Kolhapur, Karad, Jaisinghpura, Satara, Belgaum regions.

Visitors from user sectors such as agriculture implants, automobile, and auto components, construction, die and mould, engineering goods, foundry, railways, textiles, and many others visited the expo.

On this occasion, IMTMA also signed a memorandum of understanding (MoU) with the Centre of Excellence Kolhapur Foundry & Engineering Cluster to jointly organise conferences, seminars, training programs, and workshops to enhance the competitiveness of manufacturing industry in Kolhapur region.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

ABB’s ‘Value of Reliability’ survey highlights the impact of unplanned downtime on Indian industrial businesses, revealing a substantial cost and a call for outcome-based maintenance strategies.

According to the new “Value of Reliability” survey from ABB, 88 percent of Indian industrial businesses experience unplanned outages at least once a month, compared to 69 percent globally. This costs the typical Indian business* close to INR 7 million per hour*, compared to INR 10.3 million globally. Despite this, 19 percent of Indian businesses surveyed still rely on run-to-fail maintenance.

The survey, conducted by Sapio Research in July 2023, gathered responses from 3,215 plant maintenance decision-makers globally across the metals, oil and gas, chemicals, energy generation, food and beverage, plastics and rubber, water and wastewater, rail, utilities, marine, wind sectors. It is part of a report that provides insights into how businesses currently manage maintenance and how they can reduce unplanned downtime.

The findings demonstrate the importance of equipment reliability and maintenance. Globally, ninety-two percent reported that maintenance has increased their uptime in the last year, with 38 percent reporting an improvement of at least a quarter. Also, three-quarters of respondents said that reliability positively impacts their business reputation and financial performance, and helps them meet contractual obligations, prevent waste and secure repeat business. Reliability was rated by respondents as the top priority when purchasing new equipment.

Looking forward, 60 percent plan to increase their investment in reliability and maintenance in the next three years, with a third planning to boost spend by more than 10 percent. Nine in ten respondents expressed interest in outcome-based maintenance agreements. Under these, operators pay service partners based on achieved outcomes, such as increased uptime or energy efficiency. This results in efficient and effective service delivery with predictable cashflow.

Speaking about the results of the survey, Amit Gupta, Division President, Motion Services, ABB India said: “The study’s findings make it abundantly clear that our industry frequently underestimates the genuine consequences of unplanned downtime, and the survey strongly corroborates this reality. This serves as a pivotal moment for our industry to shift its collective focus towards energy efficiency, recognizing the substantial impact of downtime. It’s paramount that we invest in bolstering reliability, incorporate digitalization to enhance decision-making, and adopt a forward-thinking, outcome-based approach for the long term. With this in mind, industrial businesses should aim to progress from a high-risk run-to-fail maintenance approach to a long-term outcome-based strategy. This will improve reliability, business reputation, competitivity, cut costs, and provide peace of mind – empowering businesses to focus on their core competence.”

This new, outcome-based model to maintenance will help industrial businesses meet incoming emissions targets and regulations as the world fights against climate change. In addition, it will help overcome the industry skills gap as experienced technicians reach retirement age.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Industrial Metaverse, integrating digital twin, artificial intelligence, edge and cloud computing, to provide greater efficiency and sustainable benefits for Siemens.

Siemens Limited achieved a milestone for its Siemens Xcelerator platform with the inclusion of 100 India-relevant digital use and reference cases across multiple industries such as Food & Beverage, Data Centers, Commercial Buildings, Power Utilities and others. Siemens Xcelerator is an open and evolving digital business platform that comprises a comprehensive, curated portfolio that includes digital and Internet of Things (IoT)-enabled offerings (software, hardware and digital services) from Siemens, and certified third parties. Part of the Siemens Xcelerator portfolio is Industrial Operations X, an open and interoperable portfolio for automating and operating industrial production and Building X, a scalable digital building platform to digitalize, manage and optimize building operations.

Tata Consultancy Services (TCS), Koncept Engineers, Safex Technologies and Sonicbolt Technologies were announced as Siemens Xcelerator Ecosystem Partners – a crucial component with a far-reaching impact on the digital transformation of organizations.

As a Siemens Xcelerator partner, TCS will engage with customers through a consultative process to provide holistic solutions for a Connected Digital Enterprise. These solutions will be based on the expertise of TCS in areas such as simulation, industrial automation, IoT, industrial edge, 5G, cybersecurity, product and application lifecycle management, manufacturing execution systems, enterprise resource planning, enterprise asset management and low-code application development. Koncept Engineers, Safex Technologies and Sonicbolt Technologies will provide integrated building management solutions and integration services of HVAC, fire safety and security systems. These include energy optimization, building information modeling integration, digitalization, cloud-based offerings and building automation as well as for Building X.

Peter Koerte, Chief Technology Officer and Strategy Officer, Siemens AG, said, “We have made significant progress over the past year with Siemens Xcelerator and growing a powerful ecosystem. With India’s economy continuing its high growth momentum aiming to double its GDP in the next 7-8 years, Indian companies have a unique opportunity to accelerate their digital transformation with Siemens Xcelerator portfolio which includes latest technologies such as industrial AI, industrial edge, digital twin and 5G.”

Sunil Mathur, Managing Director and Chief Executive Officer, Siemens Limited, said, “We have achieved a milestone of 100 India-relevant digital use cases, which are now available on Siemens Xcelerator platform. Together with our Siemens Xcelerator Ecosystem Partners, we will be able to support the increasing demand for digitalization and decarbonization solutions in India.”

Regu Ayyaswamy, Global Head, IoT & Digital Engineering, TCS, said, “TCS brings deep knowledge of Industrial IoT and digital engineering across a wide client portfolio and expertise in Siemens Xcelerator solutions. With TCS’ ‘Bringing Life to Things’ framework, enterprises can maximize value from a Connected Digital Enterprise by responding to physical context with digital intelligence, accelerating digital product creation, enabling neural manufacturing and becoming sustainable by design.”

Many of the use cases were on display at the fourth edition of Siemens India Innovation Day 2023 in Mumbai, where Siemens showcased a range of technology innovations and customer references on digital transformation through an Ideas Marketplace, Co-Labs and Siemens Xcelerator Hub.

In his Keynote Address at the Siemens Innovation Day 2023, Peter Koerte outlined the power of the Industrial Metaverse which is an always-on world, where real machines and factories, buildings and cities, grids and transportation systems are mirrored in the virtual world. It has the potential to solve real-world problems by integrating cutting-edge technologies such as digital twin, artificial intelligence, and edge and cloud computing. It will enable users to simulate and test different scenarios, and to work on real things together virtually, in real-time, and from anywhere – whether designing buildings and power grids or servicing machines. This will result in reduction of costs, emissions, and resources.

Acknowledging the major challenges for India’s industry, in its recent paper, Siemens highlighted the five megatrends that are transforming the global economy. These megatrends are seen to be shifting the geopolitical balance of power, and profoundly impacting the global workforce: demographic change, urbanization, glocalization, environmental change & resource efficiency, and digitalization. Siemens’ mission is to present solutions, along with the Siemens Xcelerator partners, for tackling these challenges.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Inovance Technology India is for the first time participating in the Refcold show, the premier event in South Asia for the cold chain industry.

Inovance Technology India is exhibiting at the Refcold show for the first time from 12th to the 14th October. The show, which is being held at Chennai Trade Centre in Chennai, is the largest exhibition in South Asia on cold chain, Industrial refrigeration and reefer transportation. At Hall 3, Booth A189, Inovance will be showcasing a variety of industrial automation products relevant for the HVACR industry.

Products on display will include the dedicated AC drive for central air conditioning CA300, high performance MD800 compact AC MultiDrive, and the MD290 and MD310 AC general purpose drives, as well as the SV660N high dynamic performance servo drive with the MS1 high dynamic servo motor. The newly launched Easy Series high performance, compact, EtherCAT-enabled PLC will also be showcased, along with the compact GL20 and flexible GL10 I/O module families. There will also be two PLCs available for visitors to view and learn about: the H5U and the AC810. Finally, to complete the industrial automation packaging offering, Inovance will also be showing the IT7000 high functionality HMI.

Anil Kumar, Managing Director of Inovance Technology India, says: “Our skilled technical team will be on hand and ready to welcome you at our stand at Refcold Expo. We have in-depth knowledge of all the industrial automation challenges faced by the HVACR industry, and we’re here to help you out. Whether you’re an existing or potential OEM customer, a trade media journalist, or an engineering student looking for that first job, we’ll be really keen to chat. So please stop by to meet us at Hall 3, Booth A189.

For more info, please contact marketing manager of Inovance Technology India, Urvashi Singh on urvashi.singh@inovance.ind.in or +91 98731 67971.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

YASKAWA India’s TechXperience Day 2023 showcased cutting-edge robotic automation solutions and was a testament to their commitment to excellence, strengthening bonds with valued Japanese customers.

YASKAWA India, a leading solution provider for cutting-edge robotic automation, hosted an event that has made an indelible mark on the world of industrial technology. The “TechXperience Day 2023” occurred at YASKAWA’s Robotic facility in Manesar, Haryana, on September 13, 2023. This exclusive gathering featured Japanese customers and highlighted YASKAWA India’s steadfast commitment to excellence and customer satisfaction.

The event brought together YASKAWA India’s esteemed Japanese accounts customers from various companies, allowing them to experience innovative technologies and cutting-edge robotic automation solutions.

The TechXperience Day commenced with a warm welcome, where each guest was presented with a rose bouquet and expressions of gratitude. Mr. Ajay Gurjar, COO of the Robotic Division, delivered his opening remarks in Japanese language, setting the tone for the event by emphasising the company’s commitment to its Japanese customers. The audience was then treated to an informative presentation by YASKAWA India, conducted in Japanese by Mr. Makoto Horikawa, Deputy General Manager – Business Development. This presentation provided valuable insights into YASKAWA India’s pursuit of excellence and the values, it delivers to its customers. Mr. Hidetoshi Maeda, Chief Technology Officer of the Robotic Division, concluded the event with closing remarks, all delivered in Japanese language, further underlining the global unity of YASKAWA.

A comprehensive tour of YASKAWA India’s state-of-the-art facility was given, where the guests could witness live demonstrations of the company’s cutting-edge robotic technologies. The event culminated with a delightful cocktail dinner that harmonised the flavors of Indo-Japanese culinary traditions. Special giveaway gifts were bestowed upon the esteemed guests as a gesture of gratitude, ensuring that their visit left lasting and cherished memories.

TechXperience Day 2023 captured YASKAWA India’s technological capabilities and served as a platform to fortify relationships with valued customers. The presence and active engagement of the Japanese customers were instrumental in making this event truly memorable.

For further information about YASKAWA India and its Robotic automation solutions, please visit www.yaskawaindia.in or contact on 24×7 Toll-Free No. 1800 102 3699,

Email: marketing@yaskawa.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The giant in Off-Highway tire manufacturing will introduce its latest technological advancements to the mining industry at the upcoming event scheduled for November 6-9, 2023, in Kolkata.

With over three decades of building a global presence in the off-highway tires segment, Balkrishna Industries Ltd. (BKT) is an agile company with a strong focus on building cutting-edge technology tires. Renowned for its extensive lineup of high-quality tires, BKT, the multinational company based in India and a major global player in the Off-Highway tire industry, will showcase various products at the event. This includes their latest offering, the Giant 57” EARTHMAX SR 468 TL tire, a specialised All Steel radial tire designed for 240-ton rigid dump trucks. Additionally, they will feature the EARTHMAX SR 53 TL tire, tailored for ultra-large loaders working in challenging rocky terrains, along with the EARTHMAX SR 34 tire.

40.00R 57 EARTHMAX SR 468 is an All-Steel radial tire specially designed for rigid haul trucks. Its unique tread design with special tread compounds makes it perfect for hard, rocky, and tough mining conditions. Its tread lug blocks with circumferential grooves and intertwined blocks ensure effective heat dissipation. Also, the sturdy square shoulder assists in ejecting loose stones to protect the tire from injury. EARTHMAX SR 468 is developed using BKT’s cutting-edge technology to carry heavy loads, deliver longer service life, and resist rock cuts and punctures.

50/65R51 EARTHMAX SR 53 is an All-Steel radial tire specially designed for loaders, dozers, and low-profile dump trucks (LPDT) operating in severe rocky conditions, including underground operations and scrap yards. The deep L-5 tread and the cut-resistant compound provide an extended wear life and excellent traction and stability.

16.00R25 EARTHMAX SR 34 is an All Steel radial tire specially engineered and designed for rigid dump trucks working in mining, quarry, logging and haulage. The non-directional block tread pattern provides excellent traction and stability on any terrain. EARTHMAX SR 34 is ideal for handling heavy loads. The robust Steel casing features excellent wear and resistance to snags and punctures. Its reinforced bead and shoulder design contribute to an extended tire life-cycle even under the most heavy-duty service conditions.

BKT is joining Kolkata’s 10th iteration of the International Mining Exhibition (IME). This event, organised by MGMI and TAFCON, is scheduled from November 6 to 9, 2023, at Eco Park, Rajarhat, in Kolkata, India. The trade exhibition offers an excellent opportunity to engage and communicate with the BKT team at their booth, numbered MO 21.

For more information, visit: www.bkt-tires.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Transforming India’s EV industry with compressed air solutions offered by Chicago Pneumatic. They are vital components for clean and efficient EV manufacturing.

India has emerged as the third-largest automobile market globally in terms of sales. The most enticing piece of the pie is undoubtedly the electric vehicle (EV) sector. The Economic Survey in India indicates a staggering 49 percent CAGR for 2022-2030, with a projected annual sale of 10 million units by 2030.

The world is decarbonising, and the shift towards EVs will revolutionise the way automotive manufacturing occurs as technology evolves for growth. From the critically important ‘Lithium-iON batteries to the ultra-modern assembly processes, manufacturers can rely on the ‘Total Solution Expertise’ that Chicago Pneumatic Compressors bring with industry-leading and energy-efficient compressed air and gas generation solutions.

Where is compressed air/ nitrogen used?

Manufacturing of battery components and final assembly (Multiple Li-on battery cells assembled in a battery pack). Also, racks and chassis which accommodate EV packs and battery layers necessitate a reliable compressed air supply. Components of battery cells (1. Electrical Foil 2. Anode 3. Separator 4. Electrolyte 5. Pouch) mandate zero contamination and nitrogen helps us achieve that.

How critical is compressed air?

Around 40 percent of the vehicle’s weight is attributed to the battery and electric propulsion system, a complex array of advanced electronics and integrated drive units. This system involves sophisticated electronics, specialised adhesives, and high-intensity chemicals—a unique combination. Contaminated compressed air can render all of these components ineffective.

What will the EV industry look for?

With manufacturers entering the lucrative charging infrastructure business, the EV ecosystem, despite stringent requirements, is poised for successful navigation of challenges and growth. Experts understand that the entire value chain in the EV manufacturing process demands nothing less than the best!

Why VSD compressors?

In most EV manufacturing processes, a variable demand for compressed air exists. This is where Variable Speed Drive Compressors come into play. By aligning the air supply with the specific air demand, they prevent unload losses and can significantly reduce energy costs. For instance, the latest generation iPM VSD compressors offer remarkable savings of up to 45 percent when compared to Base Load Compressors.

By 2030, every third two-wheeler and every fifth passenger car sold in India will be an electric vehicle, and behind this shift will be a greener compressed air and gas solution!

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The case study highlights the use of HYCUT in metalworking, leading to a significantly lower environmental impact than a conventional, mineral oil-based coolant system used for the same purpose. Internal recycling becomes possible, leading to substantially more sustainable use of cooling lubricants in the machining process chain.

Life cycle assessment of metal removal fluid systems in metalworking applications

Cooling lubricants (MWF) are widespread in industrial metalworking because their cooling, lubricating, and flushing effects enable a high-performance and economical machining process. Typically, conventional water-miscible or non-water-miscible cooling lubricants based on mineral oil are used for this purpose. However, mineral oil extraction, production, use, and disposal involve many adverse ecological impacts. Furthermore, the choice of cooling lubricants also plays a crucial role in determining the sustainability of the machining process chain.

Assessment of environmental impacts based on the example of crankshaft production.

A significant portion of the cooling lubricant is removed due to adhesion to the workpiece. Depending on the type of cooling lubricant used in the subsequent process stage, a time-consuming intermediate wash may be required. To eliminate the need for this inconvenience, Oemeta has developed the multi-purpose oil HYCUT, which can be used as either a non-water-miscible machining oil or a water-miscible emulsion. Unlike conventional cooling lubricants, it has been developed based on renewable raw materials, offering environmental benefits.

In collaboration with the Institute for Machine Tools and Production Technology at TU Braunschweig in Germany, the potential environmental impacts of the Oemeta HYCUT product series were tested through a life cycle assessment and compared to those of a conventional mineral oil-based reference lubricant system.

Application of the life cycle assessment method at an Austrian engine plant

To arrive at a holistic assessment of a product’s environmental impact, the entire life cycle is considered, encompassing everything from the extraction of raw materials and production to usage and final disposal. This comprehensive analysis factors in the resources consumed and the emissions produced throughout the life cycle, converting them into environmental impacts.

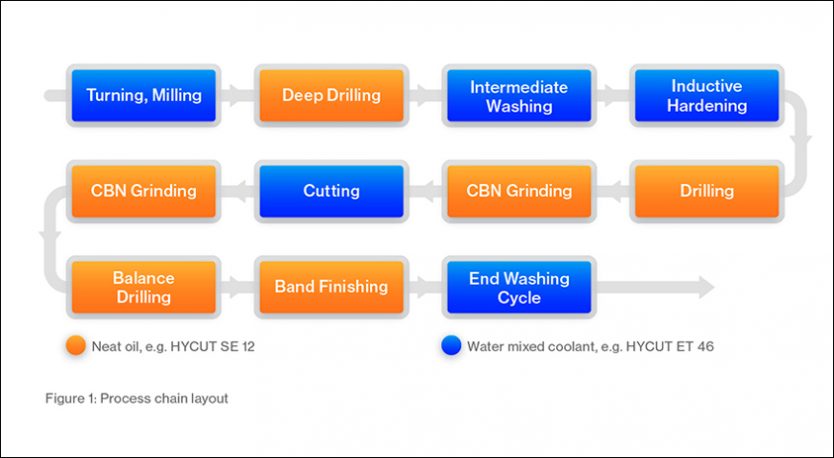

This LCA was carried out as a case study at a German car manufacturer’s engine plant in Austria. The process chain for crankshaft production was under scrutiny here: this involves the most diverse machining processes, including milling, turning, deep drilling and grinding. The process chain also involves frequent changes between water-miscible and non-water-miscible MWFs (see Figure 1).

Oemeta HYCUT offers a sound ecological balance.

In practice, the process chain already utilizes the ester-based multi-purpose oil HYCUT, formulated so that water-miscible and non-water-miscible components are compatible. Consequently, mutual entrainment of cooling lubricant adhesions on parts is not a problem, as with conventional cooling lubricants. Compared to mineral oil-based reference products, using this cooling lubricant along the entire production line is much more efficient, as it significantly reduces the need for intermediate washing and minimizes waste of the MRF.

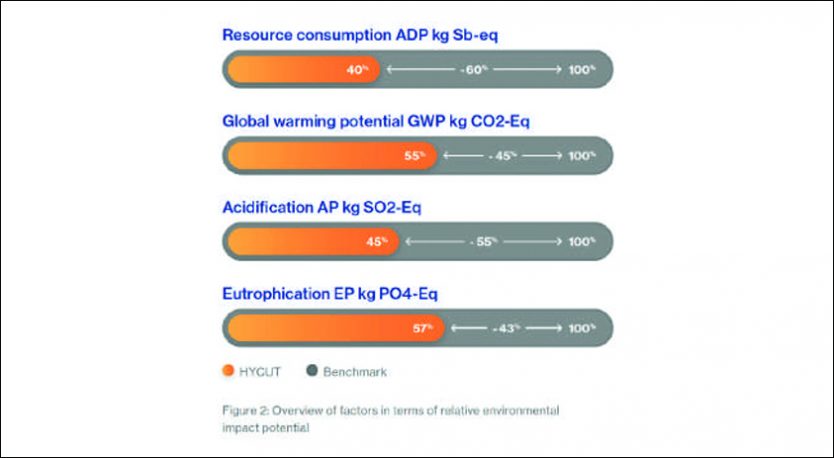

In particular, re-using the washing agent from the workpiece cleaning operation as a cooling lubricant for the machining processes positively affects the life cycle assessment. Planners tailored the production chain design to the specific lubricant to take full advantage of the multi-purpose oil. Normally, several systems are required to clean the workpieces, for example, but this was not necessary here. Using the HYCUT system in all environmental impact categories under review results in significantly lower environmental impacts (40-60 %) over the entire life cycle than in the case of the reference system (see Figure 2).

Comparisons regarding global warming potential (GWP) savings.

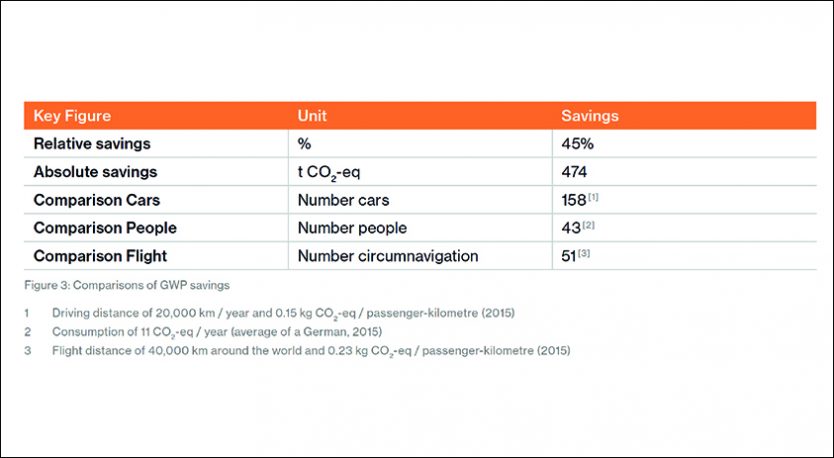

Regarding Global Warming Potential (GWP), the case in question generated savings of approximately 470 t CO2-eq in annual production – equivalent to the environmental impact caused by driving 158 passenger cars for one year[1] (see Figure 3). The absolute figures are case-specific and depend on the comparative basis, the system, and the processes under consideration. In contrast, the relative figures indicate the general comparative tendency.

The life cycle assessment thus showed that using HYCUT in metalworking leads to a significantly lower environmental impact than a conventional mineral oil-based coolant system used for the same purpose.

For more info: barthwal@oemeta.com

in.oemeta.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Various terminal blocks are available, including different numbers of terminals, terminal pitch sizes, installation methods and more. So, it simplifies connection with Autonics I/O terminal blocks and cables.

Electrical devices typically necessitate connections with other machinery across various industries. To achieve this connectivity, cables and terminals are essential.

I/O Terminal Blocks

The I/O terminal blocks serve as the means to connect multiple devices concurrently. I/O terminal blocks facilitate efficient wiring among electrical devices, ensuring a stable connection through insulating substrates. These connectivity solutions simplify installation and maintenance with straightforward connection methods. Typically, I/O terminal blocks find their placement within control panels or switchboards, enabling convenient connections and disconnections of diverse devices. Autonics offers a wide range of I/O terminal blocks tailored for various applications.

Users can select I/O terminal blocks depending on the required usage or environments. Various terminal blocks are available, including different numbers of terminals, terminal pitch sizes, installation methods and more. It makes connection easy with Autonics I/O terminal blocks and cables.

Common Terminal Blocks

Common terminal blocks allow power supply and distribution to various field instruments. Available common terminal blocks include:

- Screw connection type ACS series.

- Screwless connection type ACL series.

- Rising clamp type ACR series.

Common terminal blocks are equipped with common wiring on the PCB, not requiring jumper bars. Common terminal blocks are available in various numbers of terminal points for application in diverse environments.

· Screw Type | ACS Series

· Screwless Type | ACL Series

· Rising Clamp Type | ACR Series

Interface Terminal Blocks

AFS / AFL / AFR Series

Interface terminal blocks allow the delivery of input/output signals between control systems (PLCs) and field instruments. Available interface terminal blocks include:

- Screw connection type AFS series.

- Screwless connection type AFL series.

- Rising clamp type AFR series.

· Screw Type | ACS Series

· Screwless Type | ACL Series

· Rising Clamp Type | ACR Series

Interface terminal blocks are available in various numbers of terminal points for application in diverse environments.

Sensor Connector Terminal Blocks

Sensor connector terminal blocks are ideal for power supply to various field instruments using sensor connectors (CNE series) and delivering in/output between field instruments and control systems, including PLCs. The sensor connector type AFE series I/O terminal blocks remove the need for wire stripping or additional tools, allowing easier and time-saving connections between devices.

· Sensor Connector Type | AFE Series

Relay Terminal Blocks

Relay terminal blocks receive PLC input signals and operate loads through contact points. Available relay terminal blocks include screw connection type AB S series and screwless connection type ABL series. Relay terminal blocks are available in various relay points, rated load current, and input logic models for application in diverse environments.

· Screw Type | ABS Series

· Screwless Type | ABL Series

SSR Terminal Blocks

Solid state relay terminal blocks are ideal for receiving an input signal from PLC and operating load through non-contact points. Available SSR terminal blocks include screw connection type ASS series and screwless connection type ASL series. SSR terminal blocks feature contactless relay terminal blocks compensating for wear problems and assuring a long life cycle and high-speed response. Users can utilize various lineups with diverse SSR points, rated load current, and input logic models for flexible applications.

· Screw Type | ASS Series

· Screwless Type | ASL Series

For more info, visit www.autonics.com or connect at: india@autonics.net.in

“𝗔𝘂𝘁𝗼𝗻𝗶𝗰𝘀, For a better, more convenient world”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Wardwizard Group, a prominent player in the electric vehicle industry, announces key leadership appointments for their flagship brand ‘Joy e-bike’ to drive growth and innovation in the EV sector.

Wardwizard Group, a renowned name in the industry, proudly announces the appointment of new leaders for their flagship electric vehicle brand ‘Joy e-bike’, to spearhead the organization’s growth and innovation in the dynamic electric vehicle (EV) industry.