Save Precious Plant Operation Time Through Early Ground Fault Detection

August 25, 2021 12:27 pm

Increasing Availability via Improved and Preventive Maintenance.

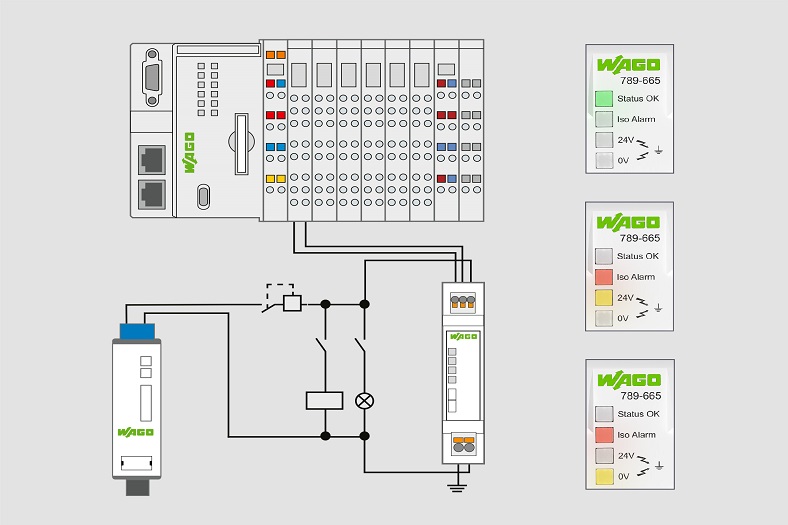

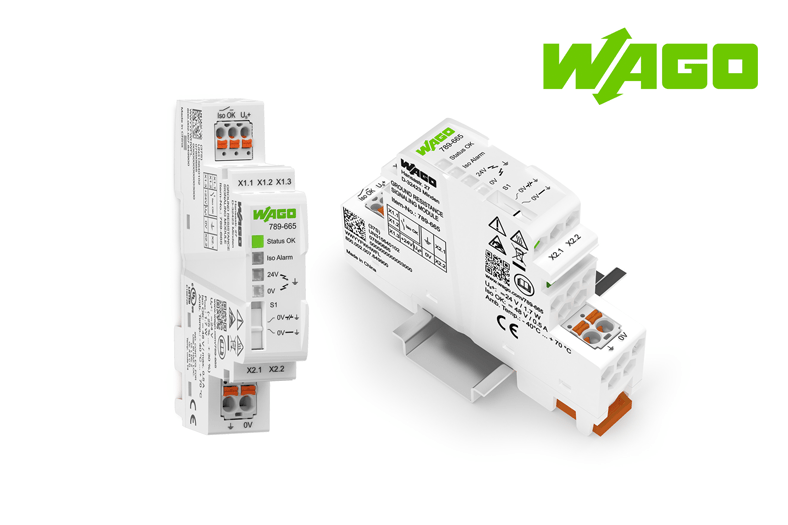

According to the IEC 60204-1 standard, measures must be taken to reduce the probability of malfunctions due to insulation faults/ground faults in a control circuit. A common option is connecting 0 V to the ground potential in the control circuit, in combination with an upstream fuse. With the launch of ground resistance signalling module, WAGO offers the possibility of detecting not only the 0 V grounding, but also the full and automatic undershooting of a non-adjustable, unbalanced insulation resistance between +24 V or 0 V of the supply voltage and ground. An integrated potential-free contact can be used to signal the Iso OK status to a controller. Additionally, on-module LEDs clearly indicate the insulation fault to the operator.

Compared to mechanical ground conductor disconnect terminal blocks, maintenance is considerably simplified. With this new module, a permanent insulation resistance test can now be performed every ten seconds instead of the standard manual ground fault test. Early detection of imminent ground faults enables improved preventive maintenance, ensuring increased system uptime. A slide switch allows the user to select the grounded/ ungrounded control circuit operating mode.

- Fully automatic measurement of the insulation resistance and early signalling of incipient ground faults via LEDs and potential-free contact

- Potential-free contact allows immediate signalling to a PLC

- Replacement of the manual test for incipient ground faults

- Reduction of the inspection interval from approx. 3 months to 10 seconds

- No risk of incorrect usage

For more info, visit https://youtu.be/T4imXwaKj2A or https://youtu.be/rE2nG_kgL0k

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi