Kennametal introduces HPX Solid Carbide Drill

July 24, 2020 12:29 pm

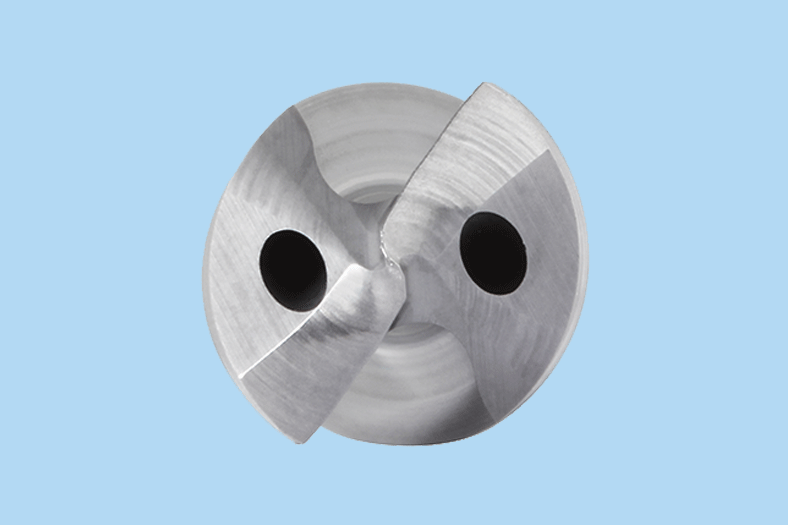

Next generation high-performance drill for steel applications sets bar for tool life, productivity Kennametal has introduced an expansion its solid carbide drilling portfolio, the HPX drill for high performance, large volume drilling in steel. Designed to quickly and efficiently punch holes up to 8xD in any ISO-P steel material, the HPX drill provides up to twice the tool life and three times the productivity compared to competing products, even in dry or minimum quantity lubrication (MQL) applications.

What makes the HPX drill the superior choice for Steel applications? The difference is in the design. Steels are used for a wide variety of automotive, commercial, and industrial applications, often in production volumes where maximum tool life and throughput is critical. Yet steel creates a high degree of mechanical loading during drilling operations resulting in forces that lead to rapid tool wear and chipping of the tool’s more vulnerable corners. Kennametal has eliminated this failure point by applying a small corner chamfer and straightening the HPX drill’s cutting edges. Together with the rounded margin lands running down the length of the flutes, this serves to stabilize the drill while reducing friction.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.