Installation solutions using the safety Fieldbox and the SD-Bus from Schmersal

February 9, 2021 12:23 pm

With use of IoT increasing in every manufacturing one of the main issues is security and safety, Schmersal provides Safety Field-box and SD-Bus as one solution for the problem.

For many companies, maximising cost-effectiveness is still one of the most important objectives. The increasing digitalisation and networking of the production environment offers significant potential for higher productivity, for example by collecting and evaluating large volumes of data to optimise manufacturing processes. The Schmersal Group supports this objective with a wide range of efficient systems for functional safety that are individually adaptable, fail-safe in operation and also reduce wiring. Some examples are installation solutions using the new Safety Field-box and the SD bus from Schmersal.

Cost-effectiveness is also an important aspect of functional machine safety. For this reason, Schmersal focuses on developing system solutions that guarantee safety with a reasonable effort, for example that are not over-dimensioned, and which contribute to productivity increases wherever possible. Very often safety switchgear that performs various functions, such as safety sensors and safety interlocks, must be fitted, installed and integrated into the safety circuit of not only complex machines and systems. Schmersal has developed the Safety Installation Systems for these cases where the user wishes to have access to information from the safety circuit for activities such as fault diagnosis: The passive distribution module (PDM) and the passive field box (PDF) enable mixed series connection of up to four purely electronic safety switching devices. With these installation systems the machine manufacturer or electrician does not connect the machine’s safety switchgear to the safety controller or the associated safety relay module, but to a separate wiring module that can be installed in the control cabinet or in the field. There, the signals are bundled together and forwarded to the evaluation unit or to the safety control unit. The safety switchgear is permanently connected in series for a safety function by the wiring modules. This considerably reduces the wiring work – and the user continues to use their existing safety evaluation unit.

Simple plug & play solution

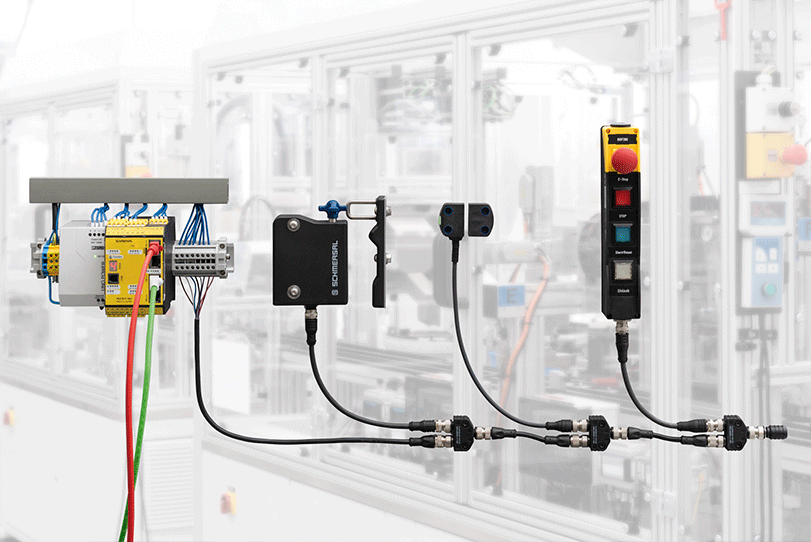

The new Safety Field-box with Profinet/Profisafe fieldbus interface from Schmersal offers more flexibility. An eight-pin M12 connector enables the connection of all common types of safety switchgear: electromechanical safety switchgear, electromechanical and electronic safety interlocks with single or dual-channel control, safety sensors, optoelectronic protective devices and also control panels. This does not only apply to the Schmersal Group safety switchgear range: Safety switchgear produced by other manufacturers can also be connected simply by using an adaptor. As a simple plug & play solution the Safety Field-box enables a fast and fail-safe installation and, used together with the field-bus system, cost-effective system cabling. The M12 power connector allows cables with a larger cross-section to be used. This reduces the voltage drop, and machines extending over a larger area can also be safeguarded. The Safety Field-box consequently covers typical safety concepts that are usually used for larger facilities: For example, two or three safety relays or safety interlocks can be used for monitoring the position of a single or double-leaf safety guard and an inspection hatch, a safety light curtain for safeguarding the area of an loading station and an operating panel with emergency stop button can be connected to the super-ordinate safety control system via the Safety Field-box An integrated digital input on each eight-pole device slot of the Safety Field-box enables the evaluation of the diagnostic signals from all connected safety switching devices and a wide range of operating data, helping to improve process transparency. This information can be used to detect irregularities and enable prompt intervention if service is considered necessary.

Cost-saving, lean wiring

Economic safety solutions are also possible using the SD bus (SD = serial diagnosis) from Schmersal. Safety interlocks and sensors can be easily wired in series via Y-adapters and standard M12 cables (Plug & Play) or a conventional connection on the terminal strip in the control cabinet. The non-safety related diagnostic signals are transmitted via the SD interface. The locking and unlocking of safety interlocks also takes place over the SD bus. This saves control system inputs and outputs. All common fieldbus protocols such as PROFINET, PROFIBUS, EtherNet IP, EtherCAT, ModbusTCP, etc. are available as communication interfaces to the control system.

All of the Protect PSC1 series safety controllers have an SD bus master in the version with an integrated fieldbus gateway. Up to 31 sensors with extended diagnostic functions can be connected directly to the compact controller PSC1 and evaluated via the integrated SD bus gateway. In addition to the standard diagnostic function “Safety device actuated or not actuated”, these safety sensors can transmit further information such as “Actuator near limit”, the temperature in the sensor, error messages such as cross-circuit, over temperature, internal device error, communication error, status output Y1/Y2, etc. This solution also enables safety switching devices to be replaced before the end of their service life. Consequently, the SD bus is an important component of systems for condition monitoring and predictive maintenance, especially for more complex machines

The use of the SD bus is particularly beneficial when machines are equipped with many safety guards or access hatches, for example filling machines, where the safety guards provide access to the workstations (feeding, filling, closing, labelling etc.). With the series connection of sensors and safety interlocks using SD bus, then practically only one cable harness is routed through the entire machine and the system can be used for up to approximately 31 safety switching devices. This enables very streamlined wiring and helps reduce costs. Wiring the sensors in series does not reduce the performance level (suitable for applications up to PL e). Different safety functions that communicate via the SD bus can also be formed into groups. The BDF 200 control panel from Schmersal now also has an SD interface. Efficient safety solutions can be created by combining the control panel with the AZM201 door interlock, for example for large production areas where robots are operating, as can be found with extensive guarding around robot workstations with many access doors. Wiring in series allows such work areas to be safeguarded with minimal wiring effort.

Safety interlock with two safety functions

The AZM201D version offers two independent safety functions in one device. Safety function 1: Door closed, but not locked. Safety function 2: Door closed and locked. Two safety outputs are available for each safety function. Safety function 1 is typically used when operating robots in setup mode. Under these conditions it must be ensured that the operating personnel are cannot be inadvertently locked into the robotic system enclosure. However, the facility must be safely shut down if other unauthorised persons enter the enclosure. The dual function eliminates the need for an additional safety sensor for use when operating in setup mode.

Schmersal System Configurator

To simplify the best safety solution for the application in question Schmersal has developed a new web-based design tool for various installation systems – SD Interface, IO Parallel Wiring and Safety Fieldbox. The Schmersal System Configurator calculates the supply voltage to each device according to the wire length and cross-section and evaluates it according to a traffic light system. For example the supply voltage comes below a minimum value of 20.4 V, the display will switch from green to yellow and, if lower than 19.5 V, to red. In this case it is advisable to select an alternative installation solution, such as a passive field box instead of a series connection with Y-distributors. The best configurations can be stored. Parts lists can also be created, meaning that the user is just a click away from the best and most efficient safety solution available.

For more info: www.schmersal.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.