Industrial safety checklist recommended to avert mishaps

May 16, 2020 12:57 pm

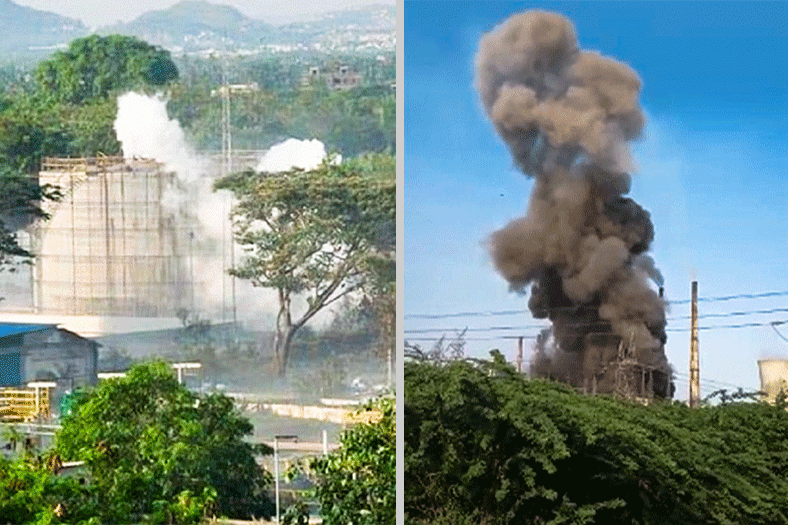

In the age of COVID-19 where everyone is concerned about health and safety, including at offices and factories, came another day that blighted the history of industrial safety. On 7th May 2020, there was a gas leakage reported early morning at LG Polymers’ factory in Visakhapatnam, Andhra Pradesh, because of which around 11 people died and over 1,000 were affected due to the spread of styrene monomer gas. The factory had resumed operation after almost 40 days with 33 percent workers. Post the incident, Andhra Pradesh Chief Minister YS Jaganmohan Reddy announced ₹1 crore as compensation to the victims’ families.

On the same day in the afternoon, news arrived from Shakti Paper Mill in Tetla village, Raigarh, Chattisgarh about a gas leakage. Around seven workers who were cleaning an open tank fell sick after inhaling the toxic gas and were hospitalised. The mill, which had remained closed since the COVID-19 lockdown was announced, had begun cleaning work to resume operations soon. The mishap came to light only after hospital authorities alerted the police.

As people grappled to come to terms with these two leakages that occurred within a few hours apart of each other, news came again from Tamil Nadu in the evening, when eight workers sustained burn injuries in a boiler blast at NLC India Limited’s thermal power station (TPS) II in Neyveli. The company suspects that overheat and high pressure might have caused the explosion of the outlet unit of the boiler.

However, the exact cause of all these accidents has not yet been revealed. In an era when newer and better standards of industrial safety are being implemented across industries, it is truly unfortunate that these plants caused some heavy losses of human life and property, leading to the deaths and injuries of not only the workers of the factories, but also those living near these outlets. It is hoped that factories and offices resuming operations amidst and after the lockdown take more steps to safeguard their workers and employees not just against the coronavirus, but also against such untoward mishaps.

In light of these events, Rajesh Nath, Managing Director, VDMA India, stated, “Three separate accidents, over the last couple of days, killed many and left several injured. One in Andhra Pradesh, in styrene gas leak at a polymer plant in Vizag, second in Tamil Nadu, a boiler at an NLC India thermal power plant in Cuddalore exploded, and the third in Chhattisgarh, due to a poisonous gas leak at Shakti Paper Mill in Raigarh. The three tragic incidents, immediately after restarting after a fortnight-long lockdown shows that a complete safety audit must be carried out for the entire unit before taking up starting activities.”

He added, “To minimise risk, employees operating specific equipment need to follow proper industrial safety measures. They need to be sensitised and made aware of the need to identify abnormalities like strange sounds or smell, exposed wires, vibrations, leaks, smoke, abnormal wobbling, irregular grinding or other potentially hazardous signs which indicate the need for an immediate maintenance.”

Sohrab Kothari, Co-founder, SAHAS Softech LLP added, “Firstly our sincere condolences to the lives affected due the fatalities and injuries of the Vizag gas leak, Chattisgarh gas leak, and the Neyveli thermal plant. Manufacturing industries should take workplace health and safety procedures at utmost importance for the well-being of both employees and employers because human loss is immeasurable and intolerable. Industrial safety measures like stress-free environment, proper protective equipment, staying alert of any irregular activities in operations, and proper maintenance checks can avoid such tragedies to a great extent. Continue to be smart. Continue to stay safe.”

Dr. Suneel Pandey, Director, Centre for Waste Management, TERI, stated, “When you look at reports from experts regarding the Vizag gas tragedy, the incident occurred due to long-term storage of a chemical called styrene in a tank during the lockdown period. Styrene is a monomer used for making polystyrene, which is a plastic used in many applications. Styrene needs to be stored at low temperatures in the range of 20-22°C as a liquid. But when the temperature increases, liquid styrene starts vaporising into gas and then becomes dangerous because the gas can then leak and travel to large distances. The experts who visited the plants found that when the plant was resuming operations, the computer programme that was monitoring the temperature was not functioning properly, as a result of which the temperature increased and the styrene became volatile. Unfortunately, the gas valve which was also lying idle for a long time during the lockdown couldn’t function, causing gas leakage across a 2-km area. In this case, it was basically due to instrumental error that the gas got released, and declaring the event as a chemical emergency also took time. Hence, so many people suffered due to the gas leakage.”

He added further, “Whenever such chemical storage plants are to be restarted, a whole emergency preparedness drill should be done to as part of chemical management emergency preparedness. Mock drills have to happen from time to time so that in any eventual emergency, corrective action can be immediately taken. There should also be more than one layer of emergency checks so that even if the software is not functioning and there is an erroneous result displayed, the other layers of emergency check will come into action and protect against such dangerous incidents.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi