Honeywell converts Low-grade Plastic Waste into High-Quality Oil

November 18, 2021 5:32 pm

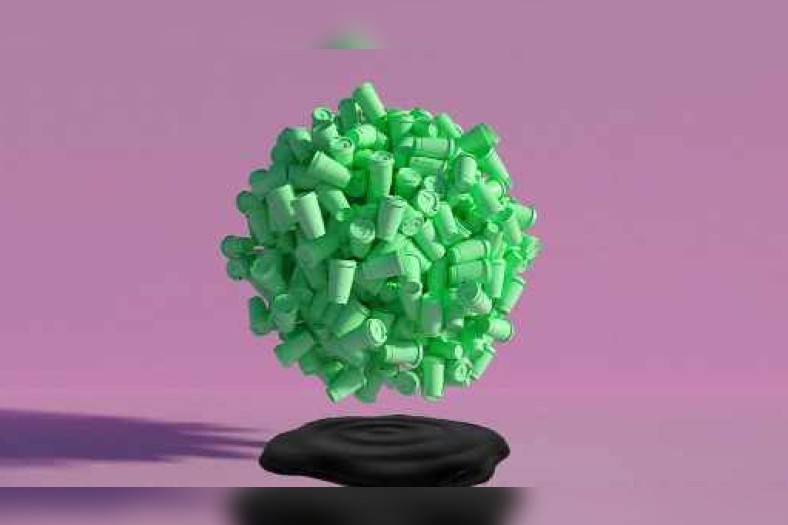

Honeywell International Inc., developed a commercially viable method to melt down low-grade plastic waste and turn it back into oil that’s good enough to feed into a refinery.

The maker of chemicals, automation equipment and aircraft parts is teaming up with the Spanish infrastructure company Sacyr SA to build and operate the first plant using the process; a facility they expect will transform 30,000 metric tons annually of mixed plastic trash into refinery feedstock.

Honeywell is using technology it has honed for decades at its UOP unit to weed out impurities in hydrocarbons before they are refined into fuel and plastics, said Gavin Towler, chief technology officer at the company’s Performance Materials & Technologies unit. That’s being combined with automated systems to pick through bales of plastic trash and cull out unwanted materials.

“Now, we’re at the point where the picking technology and the conversion technology can go together,” Towler said in a telephone interview. “We can handle mixed plastic waste. We can make it into high-quality oil.”

Towler declined to disclose the cost of the plant or Honeywell’s ownership stake.

Honeywell’s offering is an improvement on technology known as pyrolysis, which isn’t new to recycling and is being used by other players. The Charlotte, North Carolina-based company is one of several trying to improve the recycling of plastics, which is now mostly limited to high-quality refuse, such as clear plastic bottles. Only about 2 percent of plastic waste is turned into reusable feedstock now, while more than half is incinerated or dumped in landfills and another 30 percent is litter that often ends up in waterways or the ocean.

Honeywell is negotiating with more partners to build and operate plants using its technology. Its direct customers will be the oil refiners that make plastics and sell them to consumer packaged-goods companies.

“What we’re seeing is the premiums that the CPG companies will pay for getting recycled plastic make the economics very good for these new plants,” Towler said.

Plastic made using the new technology can result in a 57 percent reduction in carbon dioxide emissions compared with production of the same amount of virgin plastic from fossil feeds, Honeywell said.

For more info, visit: www.honeywell.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.