Trends and challenges influence laser cutting and metal forming market growth

September 3, 2021 1:59 pm

Autonomous operations of various machines in future are going to be trend. In 2021 growth of laser cutting machine will have significant change. The global laser cutting machine market size at USD 3455.4 Mn in 2020 will register 8.2% CAGR and reach USD 4738.8 million by 2026.

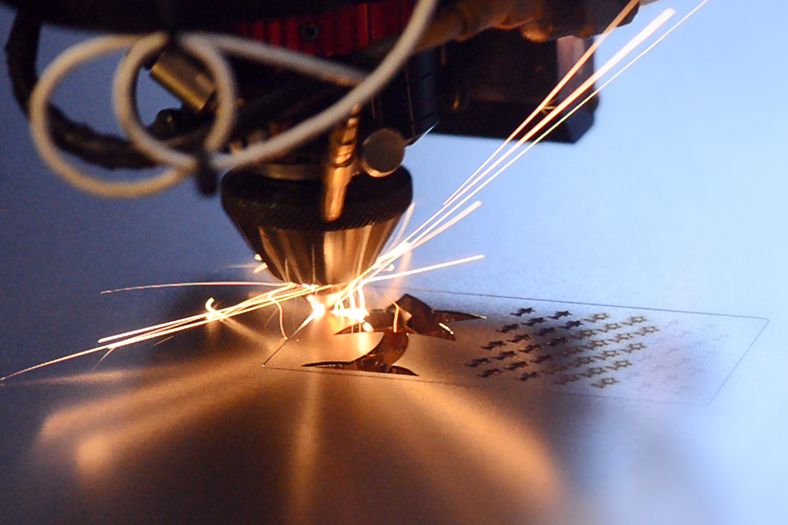

Laser cutting technology – while typically used for industrial manufacturing applications, is now used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The robotic laser cutting market is driven by increased productivity with improved laser technology. Studies indicate, robotic laser cutting market is poised to grow by USD 173.13 million during 2020-2024, progressing at a CAGR of about 17 percent during the forecast period. APAC region, the largest robotic laser cutting market in 2019, will offer several growth opportunities to market.

In the emerging countries, namely, India and China, the rise in the number of industrial activities is resulting in the growing demand for steel fabrication. The global Metal Forming Machine Tools Market size is projected to reach USD 48.67 billion by 2026, exhibiting a CAGR of 5.2 percent. The industries, such as consumer electronics, automotive, and aerospace, are demanding for fabricated metals. Metal fabrication possesses a wide range of applications. Right from office supplies, such as paper clips, to airplane parts, their usage is increasing day by day; fuelling the metal forming machine tools market growth.

Advantages for SME and MSME sectors

Talking about recent enhancement, Seth from Amada India says, update in fibre laser technology has overcome many of the shortcomings of a CO2 based laser which is definitely going to help metal fabrication manufacturers. These fabricators are mostly from SME and MSME sectors. Fibre lasers are very energy efficient and fast. Apart from higher productivity, we can achieve less taper across thickness which eliminates secondary machining process. Fibre laser improves material utilisation and subsequently reduces cost of production.

Talking about updated technologies, Mukherji from Messer Cutting System stressed, SME and MSME to have updated technologies in their field of operations because helps to be more productive; better control on cost and quality and helpful for fetching new orders.

Manjrekar from Bystronic Laser India, elaborates upon latest offering, and mentions that there is tremendous potential for the large format laser with bigger table size and higher laser power like 10 KW and above in Indian Market. Machine tools segment demands quick approach in estimation with precise detailing, having better technological edge by means of the software and the efficient machine will enhance their chances to encash more business. The key is to map out your present factory capacity and align your production to the best of equipment efficiency. Better technology not only helps to increase the throughput but also reduce the down time with advance diagnostic and troubleshooting analysing capability of the Machine controller. He remarks, in the present scenario, contribution of the SME and the MSME is very critical and they consume the large share of the machine tools from the total sales. To be competent and agile they have to invest in the technology and solutions which can drive their business towards better throughput and faster ROI. He adds, “Need for basic automation has increased.”

Technologies enhancing metal forming & laser cutting

The high-technology company TRUMPF offers production solutions in the machine tool and laser sectors. JBM is working with various car manufacturers. Gupta President Strategy & Business Planning of JBM Auto Components, says, “We produce components for all international vehicle manufacturers that have a presence in India.” These include companies such as Daimler, Ford and Suzuki-Maruti. Also, “The demand for lightweight automotive components is growing rapidly,” It is no coincidence that JBM relies on TRUMPF for processing the high-strength steels.

Mukherji says, laser market is climbing the ladder of higher KW, means higher thickness of Jobs can be cut. The Investment is also reducing making them more affordable. Laser is now entering the thickness areas of Oxyfuel and Plasma cutting slowly. He says, “We balance and master the two worlds of contradictions. i.e., World of Innovation and World of Excellence, and this is what is driving us to continue to be pioneer in any emerging technology in metal cutting industry. It’s all about blending Excellence and Innovation in every part of business. Hence, we are committed to be the pioneer in future as well to bring out the latest in this industry to the customers.

“Today’s Metal forming segment is more dynamic and demanding. To cater this market, we need to be always one step ahead with what our competitors are offering. Talking of the machine tool requirement on the solution level, Manjrekar says, we are not limiting ourselves only on the machine tool side, but it expands evenly to the other equally important element of the solution also like software, automation, integration and important is the ‘People Skill’.

Safety challenges and trends in pandemic times Manjrekar notices, planning and uninterrupted execution is very important in the current scenario. “Sustain and Grow is the new mantra.” The difficult time brings in baskets of opportunities to diversify and grow, for which we need to have our manufacturing set up equipped, the effective is better factory integration and the platform where you can pull-out real-time efficiency data. He says, it is important to have a very effective safety protocol and arrangements at factory level and also in the equipment as a standard practice. Better software capabilities will help to define safer approach towards the work. I don’t see any trends impacting the machine tools, there is huge demand for the faster lead time for the machine delivery and market is showing the positive outlook.

Manufacturing efficiency in robotics Seth expresses, we are very much aware of benefits of Automation. However, the major cause of concern is higher investment cost and longer time to amortise. “There is always this impression that labour is cheaper here in India, so why should I invest in automation. But, if you look at the consistency and the increase in the productivity and the amount of time you save on the operator interruption, this automation can be a huge advantage.”

This pandemic has definitely put the focus back on the need of automation and to have uninterrupted production activity. According to Manjrekar, as per the present trend, the need for basic automation has increased due to high power laser cutting machine, which demands quick turnaround of the material to keep the pace with the productivity of the machine.

Maulik Patel, from Sahajanand Laser Technology Limited (SLTL) remarks, “The advanced technology of the Arm X5 developed by the SLTL Group is changing the dynamics of 3D cutting industries like automobile, aerospace, medical, and robotics.” With the help of contemporary technology, such as IoT and automations, the metal forming industry is undergoing brisk changes. Manufacturing is prominently dominant. The localised manufacturing sector is growing exponentially; growth forecast puts it at more than 6 times than current value by the year 2025.

Discussing about market trends, Patel remarks, sheet metal forming business is a major game-changer in many industries like, automotive, aerospace, construction, electronics, energy sectors, and many more. The sheet metal forming process is geared towards generating the final products that are quite imperative for the engaged industry sector. The fact is that manufacturing companies in developed countries are focusing on diversifying their production by setting up low-cost plants in countries, like India. Indian enterprises are rising because of Make in India and increased overseas trade relations. The metal forming applications saw a remarkable increase in the Indian market.

There have been major financial and regulatory roadblocks faced by various sheet metal forming companies. With a dynamic trend in recent years, metal forming applications saw a remarkable increase in the Indian market. Patel stated, “Finance is a major obstacle that stops a buyer from procuring quality machines, which in turn becomes a major hurdle in their growth path.” It is an absolute necessity to provide financial assistance to boost the growth of the sheet metal forming sector. Further steps need to be considered such as assessment of how profitability, loans, revolving credit and cash-flow reserves can support bolster operations in a low-revenue environment and macroeconomic policies should support capacity expansion and increase the resilience of the economy. Improving the supply chain process and lines of communication to mitigate potential problems faced during such unprecedented times. Patel says, “We conduct periodic training and have rewards in place for adhering and giving suggestions. “Workplace safety is one of the most important aspects of any kind of job and requires everyone in the company to adhere to the safety guidelines and policies in place. Workplace safety isn’t the same for everyone in an organisation. There are varied safety training standards for different team-mates depending on their role and function.

Robotic laser cutting

Further to say, the familiar blue cobots of Ann Arbor’s Universal Robots will be featured in more than 20 booths, including its own, at the FABTECH 2021 trade show at McCormick Place in Chicago September 13-16. The usage of robotic laser cutting in the aerospace and defines industry is one of the critical robotic lasers cutting market trends likely to influence the market positively in the years to come. Growing aircraft demand and the presence of a large existing base of manufacturing facilities will significantly influence and lead the robotic laser cutting market. The governments of various countries are taking construction initiatives that would also boost the market growth.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi