Rotary Unions for TSC System and sealing technology

October 12, 2021 2:37 pm

Rotary unions are a critically important element in through spindle coolant (TSC) systems.

TSC systems deliver coolant directly to the cutting edges of end mills, drill bits and other rotary tools, providing a distinct advantage over flood coolant methods. A spray of high-pressure coolant directly in the cutting zone can enhance machining processes by rapidly clearing chips, cooling work pieces and allowing extreme pressure (EP) lubricant additives to more effectively reach cutting tool edges.

TSC systems normally allow a 20 percent increase in surface cutting speed, which provides higher chip removal rates and much shorter machine cycle times. Rotary unions for TSC systems in machining centre applications must supply high pressure coolant fluids (up to 3,000 psi, 210 bar) at high flow rates while maintaining the rotary seal at high rotary speeds (over 36,000 rpm). The seal must be upheld even with intermittent operation and rotation changes. The rotary union must provide a long life without seizing, seal failure and leaks. Advanced mechanical seal materials and seal technology lie at the heart of every high performance Deublin rotary union. Standard Deublin rotary unions for machining applications always utilise mechanical seals with dual silicon carbide (SiC) faces.

SiC is an extremely hard, high thermal conductivity and wear resistance ceramic. While fluids properly filtered to remove particles below 60 microns will maximise seal life, SiC seal faces can continue to perform even with dirty media or marginally filtered coolant. Different Deublin seal technologies can be selected depending on the specific performance requirements of the rotary union application. The SiC seals have an optimised balance ratio. A balanced seal design prevents lubricant or fluid between the seal from being squeezed out or vaporised. A loss of lubrication would increase seal wear and dramatically shorten life. Balanced seals have high pressure limits, low seal face loading and low heat generation.

The higher thermal conductivity of SiC, mirror-smooth faces and balanced design keep the seal faces running cool and extend seal life. Sealing technologies encompass the seal actuation mechanisms, opening and closing the seal faces. Deublin seal technologies include closed seal, controlled-leakage, Pop-Off™, All-Media, AutoSense™ and a variety of other advanced technologies for all applications.

Critical wear parts in rotating union

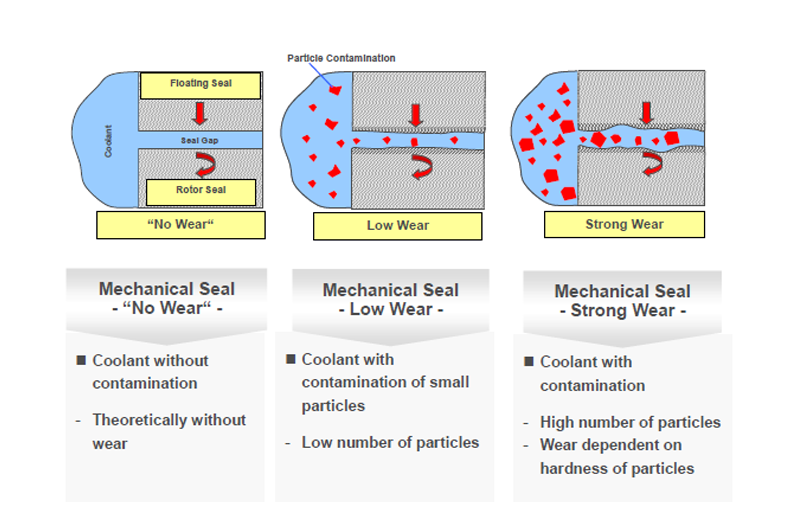

Mechanical Seal Wear

External factors that determine the rotating union life

- Coolant

- Material

- Installation

- Machining Process

- Operating Data

- Rotating Union Type.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi