KP Aero Industries Co. Ltd., improved productivity and technical competitiveness with Vericut Force

August 3, 2021 5:30 pm

Full support for factory digitisation (smart factory) from the government offices at both federal and state-level still seems insufficient for many companies to overcome resistance to sudden changes and risks that could accompany those changes.

KP Aero industries co., Ltd (herein KP Aero) is an exception. A small but well-equipped with advanced technology in the Gyeongsang province of South Korea, KP Aero has successfully implemented the smart factory empowered by the corporate culture that conceives technological innovation as a natural task rather than burdensome.

KP Aero’s successful global market debut after 30 years of self-gained technology proves it well. KP Aero produces parts for A350, B737, B777, B787, and more. Korean Air, Korea Aerospace Industries, Hankuk FIBER are also important customers of KP Aero. In 2020 while the Covid 19 significantly impacts the global aerospace industry, KP Aero could secure a deal with a major Japanese aircraft manufacturer.

“Aircraft manufacturers request lighter, more complicated, and precise parts. To meet these needs, which requires high-speed machining, we established a facility with machines that are capable of operating at an average speed of 30,000 rpm.”

KP Aero is already a user of the CNC simulation software and optimisation software VERICUT. However, when more need for precision machining is noted, and to improve the high-speed machines’ productivity, the company made a call to test the optimisation module FORCE.

“Vericut force is a solution that is already highly accepted in the global aerospace industry. The fact that KP Aero using FORCE optimisation would give an extra boost to gain customer trust and strengthen the price competitiveness.”

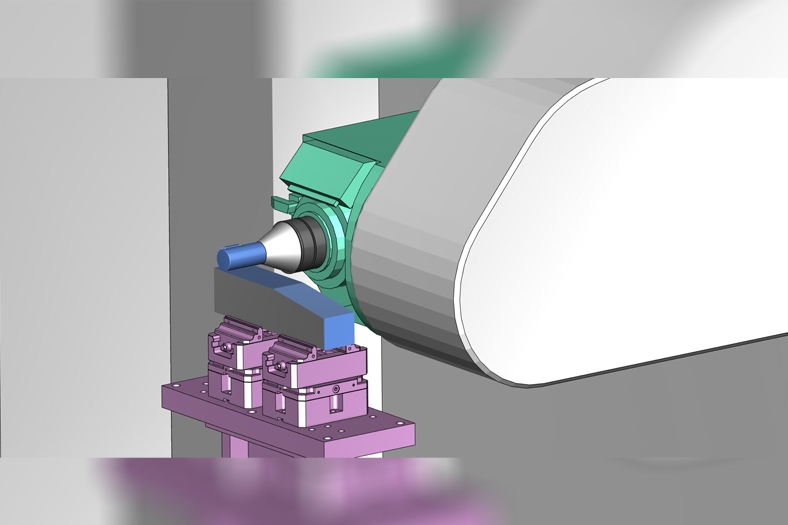

A Titanium (Ti-6Al-4V) part was machined using a 5-axis DMC- 100U duoBLOCK to test the software. To machine a part faster and safer, FORCE cuts the NC code into small segments and applies the optimal feed rate for each segment, improving the efficiency of the toolpath and eliminate any risk due to overloads. After FORCE optimisation, KP Aero saved 25 percent cutting time and eliminated tool breakage, which has been a problem while machining deep pocket corners and trims. “Performance enhancement of the company is expected thanks to FORCE that can prevent overloads and tool breakage. FORCE also provides various easy and fast-to use analytic functions and charts.”

FORCE and other VERICUT modules seamlessly connect to already established facilities. KP Aero is implementing FORCE software as a part of their smart factory processes and planning to optimize other parts’ toolpaths soon.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi