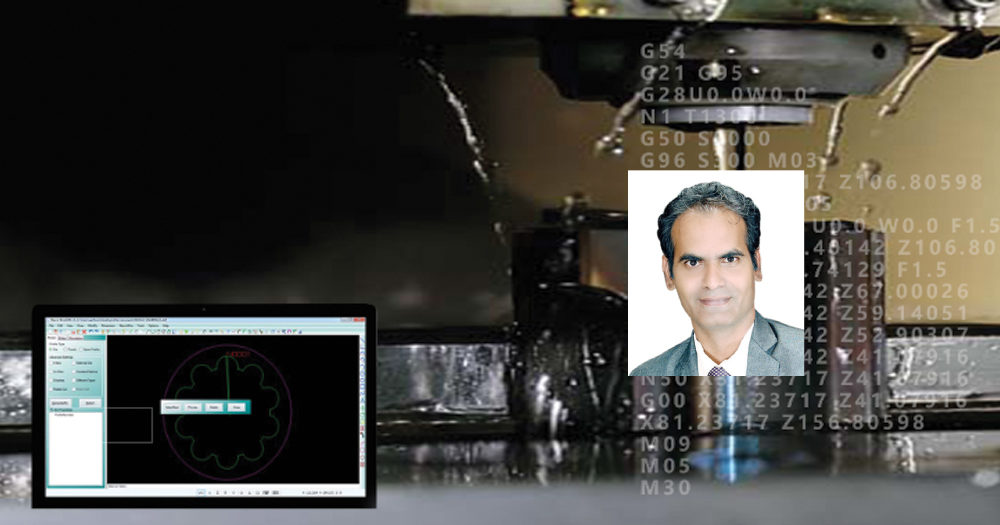

CAD Macro: Adding value to the manufacturing industry

June 12, 2018 3:24 pm

K Manickam, MD, CAD Macro Design & Solution

Our vision is to be the preferred design and manufacturing partner to our valued customers.

CAD Macro’s offering to the die & mould industry

CAD Macro offers wide range of ready-to-order solutions in terms of products as well as customised solutions based on ground requirements in the die and mould industry as their exclusive domain player. In fact, the company’s dedicated service in the CAM segment in the initial days made them very strong to conceive and lead these kinds of Tool ERP Solutions which include standalone as well as Human Machine Interfaced (HMIs). CAD Macro is one of the market leaders in wire EDM market in addition to lathe, press tool design and detailing tool. “By and large, our exclusive Tool Room ERP in the name of Shop plan is our pride and value to the core manufacturing sector. More than 1,000 happy customers in the market helping us to add more commitment from our side every single day,” claims K Manickam, MD, CAD Macro Design & Solution.

Uniqueness of CAD Macro

CAD Macro claims to be the only company having indigenised 100 per cent of its CAM and ready-to-order solutions for the die and mould industry in India. Manickam adds, “We have become successful in establishing an exclusive Tool Room ERP in the name of shop plan as the amazing result of our 12 years value journey in the tool room domain. Apart, we have the complete range of solutions in CAM and reached No. 1 space in the wire cut market.”

CAD Macro’s value proposition to the die & mould industry

The recent studies in the manufacturing sector shows that there is a huge disconnect in the demand and supply in the market due to various real-time constrains in the ground. Manickam opines, “Apart from any operational pain, we can take the reduced Turnaround Time (TAT) as the key challenge of the manufacturing segment. Eventually, it hits the second level vendors to work on reduced cycle time with highest accuracy in the floor. CAD and CAM solutions are the key to ensure accuracy, precision and to win reduced cycle time in the manufacturing sector. So, this is the ultimate value proportion we add to our clients.”

Growth drivers for die & mould industry

According to Manickam, the changing technology trends in the vertical, integrated approach in the overall production, improved tool room management systems are the key factors in speeding up the growth status of the die and mould industry and converging Indian tool room market as a promising sector. By and large, Indian die and mould industry getting matured with an average growth of 12 per cent to 15 per cent every year with consistent development on capacity building and international standards to scale from the current average market size of Rs 12,000 crore.

Market size and growth potential

According to the Indian Tool Room Manufacturing Forums, the domestic average market size of die and mould industry could touch around Rs 30,000 crore by 2021 from its current level. As a matter of fact, it demands a right mix of contribution among the research forums, government bodies, trade associations and the policy makers. The major sectors like automotive, consumer electronics, infrastructure development, mass engineering projects and national energy development roadmaps are expected to support Indian die and mould industry to win over substantial growth in the years to come.

Uniqueness of CAD Macro’s Tool Room ERP

As per the studies made after implementing CAD Macro ERP at client places, the company observed that it has improved process planning capabilities up to 10 per cent and has reduced the scheduling time up to 70 per cent against feeding alternative priorities, informs Manickam. He adds, “The TAT of projects is reduced up to 10 per cent due to effective planning supported by the company’s ERP. The operator friendly live feed has been achieved as it allows data feed through tables, barcode systems and mobile platforms. Apart, from the perspective of human resource utilisation, accountability has improved by 5 per cent wherein machine idle time tracking has improved 5 per cent. By and large, the overall profitability has increased up to 5 per cent through improved cost analysis intelligence and relevant reports.”

Bottlenecks in die & mould industry

Explaining the current challenges in the die and mould industry, Manickam said, “The critical situation in the die and mould industry is unimaginable in India due to various reasons. Invariably, the clients’ inclination towards imports, increased competition and reduced margin in the space are the key bottlenecks of the targeted industry.”

He adds, “Availing skilled labour, poor utilisation of manpower and machines, lack of advanced monitoring and scheduling tools and unorganised approach in the overall production are the key threats of the sector immaterial of its conceived growth in its landscape. Beyond anything, there are situations where the industry used to take up unsuitable tools and solutions into business and forced to lose time, money and reputation due to poor results. In these cases, the overall failure caused to the clients are unimaginable. But, CAD Macro never become a wrong choice to the clients from the quality and precision perspective.”

Keeping up with technology trends

Talking about how CAD Macro matches its growth dynamics in align with changing technology trends, Manickam said, “As a part of mapping advancements, the tooling industry is crossing the rational moves to sustain real-time factors like optimised costing, improved efficiency and advanced forecasting in all the phases. In addition, inclusion of 3D Printing for prototyping, precision machining, rapid tooling systems and utilisation of advanced CAM tools are the potential growth drivers in the Indian die and mould sector. In this context, we are very much trend mapping and advanced by all means to ensure high degree of co-ordination, precious design and advanced programming inputs across all the phases.”

Vision

“Our vision is to be the preferred design and manufacturing partner to our valued customers and a key contributor to the successful use of innovation and technology in our chosen markets,” concludes Manickam.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.