Smart Robots – Meet the new generation of robots for manufacturing.

March 15, 2017 11:57 am

The technology is changing at a fast pace every day. With the concurrence of of artificial intelligence, sensors, actuator technologies, and the mobile phone revolution, the world is at the apex of a robotics revolution. Incredible precision with the perfect blending of productivity, and flexibility comes along with robots and robotic automation. Robotic systems were assumed to be reserved for only the automotive industry or manufacturing jargons who have large production lines. However, the times have changed and are changing rapidly. Robots are becoming much more affordable, flexible, easier to operate throughout their entire life cycle, and the methods used to program them are becoming a lot easier and much more intuitive.

Growing trends in Robotics

Tore Lindstrom, Head of Robotics ABB India says, “Robots can now offer small businesses similar opportunities to increase profitability that they offer large corporation like car manufactures. Collaboration and digitalisation are reshaping the manufacturing automation landscape, and are essential building blocks of the factory of the future.”

As per Lindstorm, there are three growing trends in robotics that he believes will improve manufacturing. He says, “Collaboration, simplification and digitalisation are the three trends. Today, thanks to their flexibility and ability to be deployed rapidly, collaborative robots support and augment the capabilities of skilled workers from SMEs, to large corporations particularly at repetitive and dull tasks.”

Lindstorm states that simplification, will make installation, commissioning and programming of robots easier. “A good example of simplicity is intuitive programming, which anyone can do from the world’s largest auto makers to the local baker, he says. “Finally, effective plant management will be dependent on digitalisation, or the ability to unlock the power of the internet,” points out Lindstorm.

Increase in digitalisation and networking

The outburst of technology has indeed revolutionised the sector of robotics. The world has had a tectonic shift in the usage of technology with the dawn of software and the ease in embedding various hardware for multiple applications have boosted the usage of robots across industries.

When it comes to the revolution in the field of robotics, Michael Schmidt, Director Corporate Communication and Strategic Marketing, Carl Cloos Schweisstechnik GmbH says, “Across industries, digitalisation and networking become more and more important. Industry 4.0 signifies that the individual components within an automated system communicate independently with each other.”

Schmidt feels that it is this that brings huge challenges for support systems such as sensor technology, image processing, software and interfaces. Furthermore, according to him, safe solutions for the rapid transfer of big data are a necessity. In addition, the automatic generation of programmes further increase the requirements for robots, especially with regard to speed, rigidity and precision.

Collaborative Robots, the latest dimension of robotics

Collaborative Robots, commonly known as Cobots, are designed to work with humans and assist them with a variety of tasks which help to automate and streamline repetitive and potentially unsafe processes thus, ensuring safe work environment while increasing productivity and efficiency. A research conducted by MIT students at a BMW factory, concluded that teams made of humans and robots collaborating efficiently can be around 85 per cent more productive than teams made of either humans or robots alone. Also, the cooperative process reduced human idle time by virtue of its pace-setting ability.

“Collaborative robots safely work alongside humans (subject to application risk assessments), without any danger of getting hurt, and more as a worker’s assistant or a third arm which was not possible in the case of traditional industrial robots,” says Pradeep David, Country Head – India & Sri Lanka, Universal Robots.

Industrial robots have been around since 1961, when GM first deployed a robot in their plant. A significant change happened in 2009, when collaborative robots brought robots out of cages and into the open to work hand-in-hand with operators. This was a revolution in the field of robotics, as hitherto, robots were considered dangerous as they could hurt and even kill people. The Manesar plant incident is still fresh.

Robotics to boost productivity

“The revolution that’s happening everywhere in the field of robotics is definitely commendable. We are seeing a quantum leap in use of robots elsewhere as well as in India. Using robots in the industry increase the productivity which helps one to meet ever increasing market demands. However, robots can be very unsafe of the risk associated with the robots are not identified and safety procedures are not followed,” says Sanjay Kulkarni, Managing Director, Pilz India.

According to Kulkarni, India is still expanding its manufacturing industry and the use of robotics and its effect shall take some years be realised. “Nonetheless, the use of robotics in the manufacturing will surely boost the productivity to help users sustain in the world of competition,” he says.

With the rising opportunities for robotics and also the increased awareness about their applications and the functioning, industries are coming up with many options in this vertical. We take a look at some of the offerings that have stirred the industrial corridor.

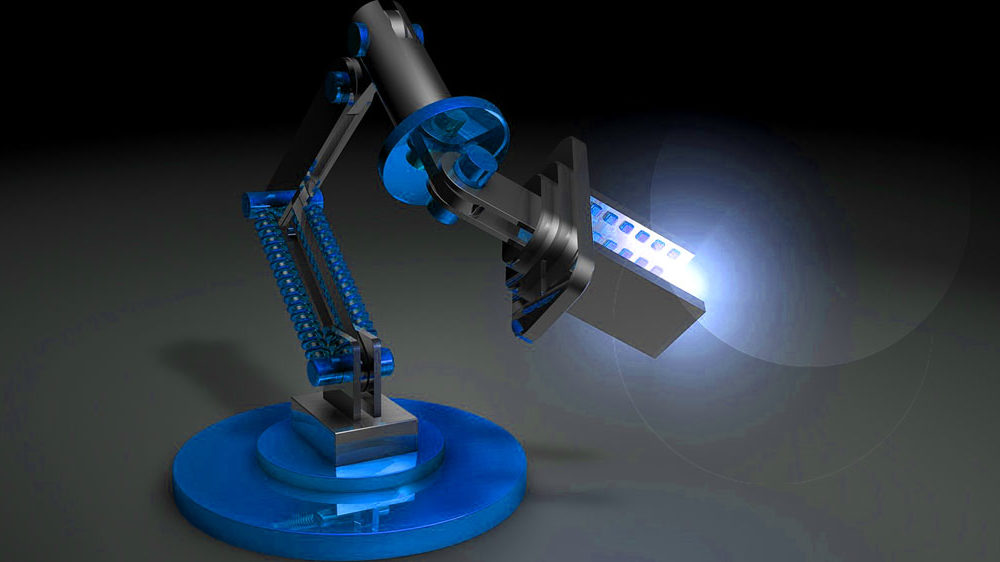

Cobots by Universal Robots

Speaking about the formidable role of collaborative robots, David says, “Operators with no programming experience can quickly set up and operate these ‘Cobots’ with intuitive, 3D visualisation. Earlier it used to take weeks to set robots at one place now it can be done within half a day. Changing the location of robots was also a huge and costly affair but now moving robots to new processes is fast, affordable and easy and gives the agility to automate almost any manual task and they can re-use programs for recurrent tasks.”

Universal Robots are a manufacturer of Cobots. Throwing light on the offerings in this sector, David says, “Safety is built into UR ‘Cobots’ – there are about 30 patents for the technology being used. This is the key which separates industrial robots from ‘Cobots’. There are 4 types of collaborative operations as per ISO TS 15066: Safety rated monitoring stop, hand guiding, speed and separation monitoring, power and force limiting.”

Universal Robots, having deployed over 11,000 ‘Cobots’ globally is contributing in the field of collaborative robotics by making robot technology accessible to all levels of industry. “With the technology advancements of Universal Robots, there is growing potential to safely combine the power and precision of robots with the creative and problem-solving ability of humans. The new technical specifications published by the ISO Committee will further emphasize the safety and risk assessments of ‘Cobots’,” boasts David.

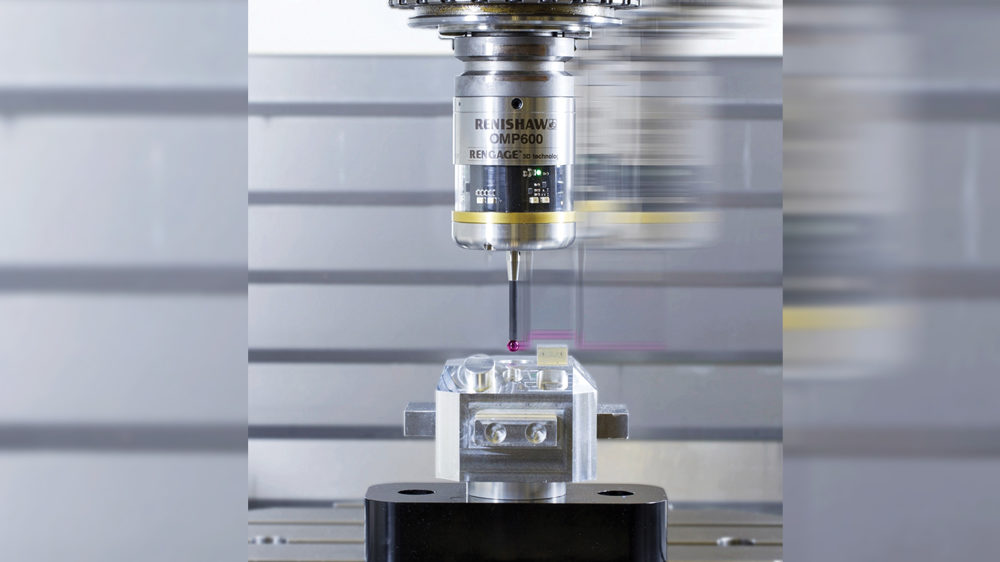

QIROX robots for efficient welding

“With the QIROX robots, positioners and special purpose machines CLOOS develops and manufactures customer-specific automated welding systems so that our users are able to meet the growing requirements of the automated welding technology,” says Schmidt.

The portfolio comprises simple, compact systems as well as complex, chained systems with automated workpiece identification and loading and unloading processes. Already, in complex automation systems by CLOOS all over the world, tool carriers, robots, power sources and master controllers successfully communicate with each other. “This year, CLOOS presents a new controller and the new programming surface for the QIROX robots. They offer an even more user-friendly, intuitive operation, a considerable reduction of the programming times and a very dynamic movement of the QIROX robots for efficient welding,” he informs.

Safe man- machine interaction

Pilz believes in Safe interaction between man and robot where man and robot can work in close proximity with each other. Sharing about the latest offerings by Pilz, Kulkarni says, “We provide safety services from process analysis to risk assessment and CE Marking of robot. Then our whole range of PSEN sensors along with control technology can be used to implement ensures safe man robot applications. Our range of PSEN sensors like safety gate systems, light barriers, and 3D safe camera systems are specially developed for robotics industry.”

‘YuMi’ and SafeMove 2 by ABB

In 2015, ABB introduced two small parts assembly robots primarily for applications in the 3C industry. The first, and possibly the most recognisable, was YuMi, the world’s first truly collaborative robot. Sharing details about the YuMi, Lindstrom says, “ YuMi is a vision of the future that ABB believes will change the way we think about assembly automation. It can perform tasks which require a high level of precision and delicate handling such as small parts assembly alongside human counterparts. Thanks to YuMi, the traditional barriers, cages and zones are not a thing of the past.The second, our first ever Selective Compliance Articulated Robot Arm (SCARA), is a single arm robot capable of operating in a confined footprint. The robot is ideal for the small parts assembly, material handling and parts inspection.”

ABB’s advances in collaborative robotics began with YuMi, and continued in June with SafeMove2, an advanced safety-certified monitoring and control software that allows people and robots to safely work closer together without compromising productivity. The company claims that with SafeMove2 people can now work safely alongside ABB robots with payloads ranging from 6kg to 800 kg, without compromising productivity.

Adding further, Lindstrom says, “As part of our journey towards helping customers realise the potential of the Internet and helping them prepare for the factory of the future, we recently introduced Connected Services.” Lindstrom says that the Connected Services, which is a cloud-based platform is an evolution of ABB Remote Services which the company had introduced nearly a decade ago, and is a sophisticated suite of services that can reduce incidents by up to 25 percent and speed response time by up to 60 percent.

Hence, it is predominantly observed that the field of robotics is set to dominate the manufacturing sector, and that too at a rapid pace. The rise of technical verticals like artificial intelligence, along with the increasing ease in the availability of sensors and safety technologies, robotics are becoming safer and smarter. In no time, this brand new generation will be working in a variety of industries rubbing their shoulders alongside humans. This collaborative approach is set to reap massive benefits as a result.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi