“Make in India” has put India on global map

July 11, 2016 4:17 pm

Starting production of 5- and 8-litre industrial engines in India is just the first step in this direction. In future, we can even think of exporting our ‘Made in India’ engines to other countries.Bjorn Ingemanson, President, Volvo Penta

“Make in India initiative has put India on the world economic map. The programme invites foreign investors to participate in production locally, to utilise local skills and boost manufacturing and employment. At Volvo Penta, the commencement of engine production at Pithampur plant reconfirms our commitment towards the ‘Make in India’ initiative by investing in local production,” said Bjorn Ingemanson, President of Volvo Penta.

In line with the Government of India’s “Make in India” initiative, Volvo Penta plans to introduce industrial engines produced locally in India. The company will start production of 5- and 8-litre industrial engines made for Indian customers at the VE Powertrain (VEPT) plant in Pithampur, near Indore in April 2017.

Volvo Penta’s range of 5- and 8-litre engines are certified for Indian Bharat (CEV) Stage III emissions standards which are equivalent to EU stage IIIA/Tier 3 and are already in the field, powering a variety of applications including construction, material handling, raw material exploration and agriculture. The new production and assembly lines will enable versatile solutions tailored to the local market needs. The company plans to add at the VEPT plant exclusively for the Volvo Penta engines.

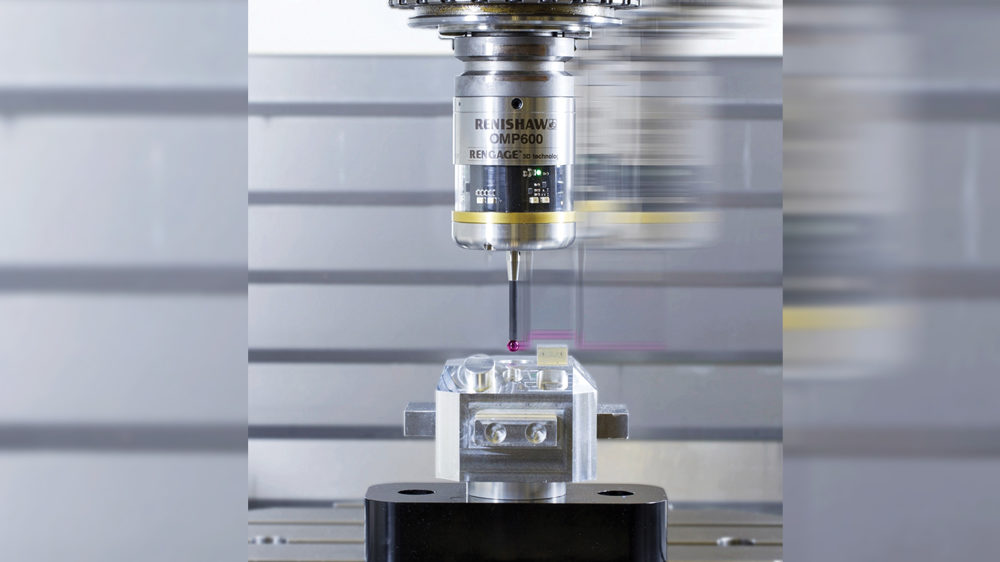

World-class facility“The plant in Pithampur is not only one of the most modern engine production facilities in India but by any global standard claims Volvo Penta’s Senior Vice President, Global Operations and Quality, Peter Hertinge. He said that the plant is highly automated with integrated testing facilities and has quality standards and procedures in place to consistently produce engines that are suitable for customer requirements and fulfil the latest and most stringent emissions regulations.

The VEPT plant in Pithampur is part of the VE Commercial Vehicles’ joint venture between the Volvo Group and Eicher Motors.

India – a land of opportunity“We see a great opportunity in infrastructure development in the country,” says Jonas Nilsson, Head of Volvo Penta in India. As the demand from customers is increasing constantly, there is pressure on contractors to complete the projects within the specified time with the cost levels they have calculated. So there is need for highly reliable and fuel efficient equipment to meet these demands.

“The ability to supply engines quickly is a key capability for Volvo Penta. Our engines enable our OEMs to make their products more competitive in the market, as well as to explore the global market,” says Jonas.

Explaining further on the opportunities in Indian market, Bjorn said, “India is a big country with a huge population having a strong demand for transports. In line with that there is the demand for different types of engine solutions for different applications. In addition, India plans to double ports capacity to 3,000 MT by 2025. This will raise demand for several types of applications where our engines would be a very good solution for the OEMs.”

Empowering OEMsBjorn adds, “We see great value in expanding upon our knowledge gained over working with OEMs in the country, and we look forward to putting that into practice for the benefit of our Indian customers.”

Highly committed to Indian marketBjorn says that Volvo Penta is exploring ways in which to fully leverage its investment at VEPT in the future. He said, “We look at all the possibilities when it comes to meeting the demand of our customers. We are open to evaluate every potential opportunity. If the situation demands, we are open to increasing our production base and broadening our product range in India. Starting production of 5- and 8-litre industrial engines in India is just the first step in this direction. In future, we can even think of exporting our ‘Made in India’ engines to other countries.”

Ambitious sales targetTalking about the company’s performance in India, Jonas said, “We are developing quite well in India and witnessing double-digit growth year-on-year.”

Taking a cue Jonas’s statement, Bjorn said, “Our ambition is to double our sales in India within next few years of course it depends on how the market develops.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi