Integration of advanced tools with old machinery can be a big challenge

June 29, 2017 3:36 pm

Digitisation in manufacturing operations builds efficiencies in processes through effective scheduling and execution.

For Indian manufacturers, the confluence of digitisation with the manufacturing processes is becoming a game changing factor as not only in terms of quality but productivity also gets enhanced. It is the need of the hour that not only large scale manufacturers but also SMEs embrace IIoT. Vinay Chauhan, Executive Director- Supply Chain, Johnson Controls-Hitachi Air Conditioning India Ltd, expresses his views on the digitisation in manufacturing as a whole.

An effective scheduling method for reliable execution

Digitisation in manufacturing operations builds efficiencies in processes through effective scheduling and execution. MRP (Material requirement planning) and ERP (Enterprise Resource Planning) systems simplify the complex situations where large number of products and processes are involved, each having multiple parts and suppliers. While, planning becomes simpler and more effective through the use of MRP and ERP systems, the execution also gets digitalised with the integration of MES (Manufacturing Execution System) as the MES systems captures the real time actual situation and identifies abnormalities.

Adoption of Smart Factory Solutions

Global manufacturers are slowly adopting a “Smart Factory” solution that includes latest technology, innovations in Industrial Internet of Things (IoT) and Advanced Analytics. The complex cyber-physical systems in a Smart Factory are embedded with networked sensors that communicate huge volumes of data within the framework of dynamic information architecture. Smart Manufacturing, a resultant of intelligent human-machine systems promotes operational efficiency and reliability while cutting down on manufacturing costs and defects.

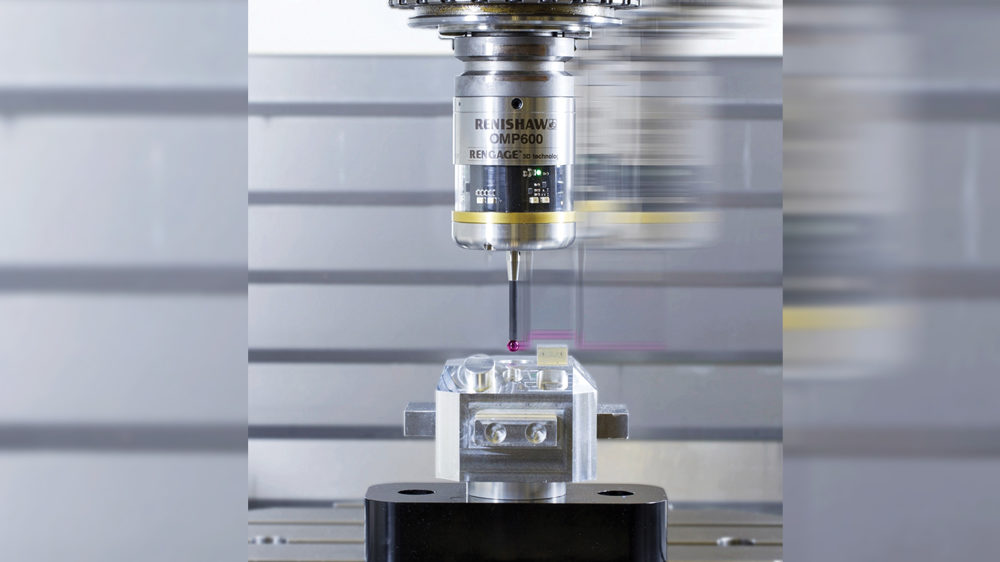

For large scale manufacturing set ups in India, digitisation or Internet of things (IoT) is nowadays becoming a basic requirement. Almost all OEMs and large manufacturing plants have basic digitisation in terms of MRP and ERP systems. Some manufacturers have integrated the advanced concepts like IoT based Smart Factory and Digital Manufacturing etc. However, the integration of advanced tools with old machinery can be a big challenge at times owing to the compatibility issues.

For small and medium scale industries in India, digitisation may be a bit more difficult as it requires basic IT infrastructure including software and hardware, which requires investment. Sadly, inability to match up with the rapid pace of digitisation is also causing these companies to lose their competitiveness.

Constant endeavour to embrace advanced technology and innovation

Johnson Controls-Hitachi Air Conditioning India Ltd has always been a technology leader and is positioned as one of the premium brands in the Indian air-conditioner industry. The company has been one of the few early players who set up their own manufacturing unit in India and generated jobs, of which its more than thousands employees are proud of today. Its manufacturing plant based in Kadi, Gujarat is one of the largest AC manufacturing facility in India. An outcome of the vibrant Gujarat Global Investors’ Summit’ 2009 where Hitachi signed an MOU to invest in Gujarat, the facility was inaugurated by Prime Minister of India Narendra Modi. With a strong indigenous D&D focus, Hitachi’s facilities spread on a plot of 1,82,000 sq. m. and has a total installed capacity of 6,00,000 RACs per annum in a single shift. Besides room air-conditioners (Split & Window ACs), the company also manufacture a wide range of commercial air-conditioners including Chiller, Ductable air-conditioners, Telecom Air conditioners and VRF system. The company’s factory manufactures 1,20,000 tonnes of Ductable units, 9,000 VRFs ODU and 300 Chillers per annum. Hitachi is not just limited to making air conditioners but also, into trading of Refrigerators and Air Purifiers. Apart from products, the company also undertakes complete projects in HVAC category. Hitachi is an innovative brand and it is their constant endeavour to embrace advanced technology and innovation in not only our products but also in our manufacturing processes. As of now, Hitachi is using almost all modules of oracle system for the manufacturing operations. In some areas, Hitachi have deployed IoT systems. Furthermore, Hitachi is in a state of planning to increase the scope of IoT and will soon extend it to all critical machinery and assembly lines.

In Room AC segment, Hitachi offers technologies like I-Clean Plus, I-Sense, I-See and Tropical Inverter Technology. Moreover, it also offers AC with WiFi technology which enables the user of AC to control it from anywhere in the world. As a socially responsible company, Hitachi makes sure that its products are environment friendly and conserve energy. In tandem with this, all of its inverter ACs use R-410 refrigerant which is eco-friendly and ensures zero-ozone layer depletion.

Efficient, eco-friendly and smart products

Hitachi’s Commercial Air Conditioners range offers smart commercial products that can easily be integrated building management systems and centrally control huge commercial buildings and factories through advanced control systems. In case of commercial building segment, Hitachi offer VRF Systems and Water Cooled Screw Chillers. Designed keeping in mind the needs of Architects and HVAC Consultants, Hitachi’s SET-FREE Kyosho Range of VRF air conditioning offers a holistic approach to air conditioning in modern offices. These units are capable of cooling and heating, offers flexibility of installation, operates at impressively low noise levels and adapts to the varied temperature requirements of different rooms within a building. Its DC Inverter driven compressor saves energy and is cost effective. It comes enabled with an air-conditioning management system that makes it easier for users to have simple, effective control of their air conditioning units to avoid unnecessary energy wastage, including overheating, overcooling and unattended operation. And with R-410A refrigerant, it is eco-friendly as well.

For Commercial and Industrial requirements, Hitachi’s Water cooled Screw Chillers offers highly efficient cooling solution. With R134A eco-friendly refrigerant, it delivers superior performance and flawless functioning. With its precise and continuous capacity control technology, user friendly LCD touch panel and high performance twin screw compressor, it provides cooling with low noise and low vibrations which is ideal for industrial and commercial purposes. At Hitachi, three pronged focused strategies are quality, innovation and advance technology which enables to deliver energy efficient, eco-friendly and smart products and this is only possible because the company is constantly integrating digitisation with the R&D, manufacturing, supply chain and other functions as well.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.