Digital manufacturing helps companies become industry-ready

June 29, 2017 3:53 pm

Digital manufacturing solutions and technologies can help companies configure optimised work flows during the plant layout stage which enables them to enhance the productivity and overall output of the company.

DesignTech Systems provides CAD/CAM/CAE, PLM and engineering services company in India. The company’s Managing Director Vikas Khanvelkar says, “We help companies leverage digital manufacturing technologies to remain at the cutting edge of technology and be globally competitive.”

Importance of adopting digitisation in manufacturing process

Today as the products are getting smarter, the product development and manufacturing is getting more digital. The modern product development technologies of today are intuitive, flexible, and easy to use. The entire products development process right from concept development, engineering detailing, product design analysis and simulation, product design validation, and managing processes, data and resources have all gone digital. The CAD/CAM/CAE, PLM and 3D printing technologies have radically transformed the way products are built thus redefining product development processes and workflows. These technologies help companies boost innovation and creativity, yet manage costs and reduce development timelines.

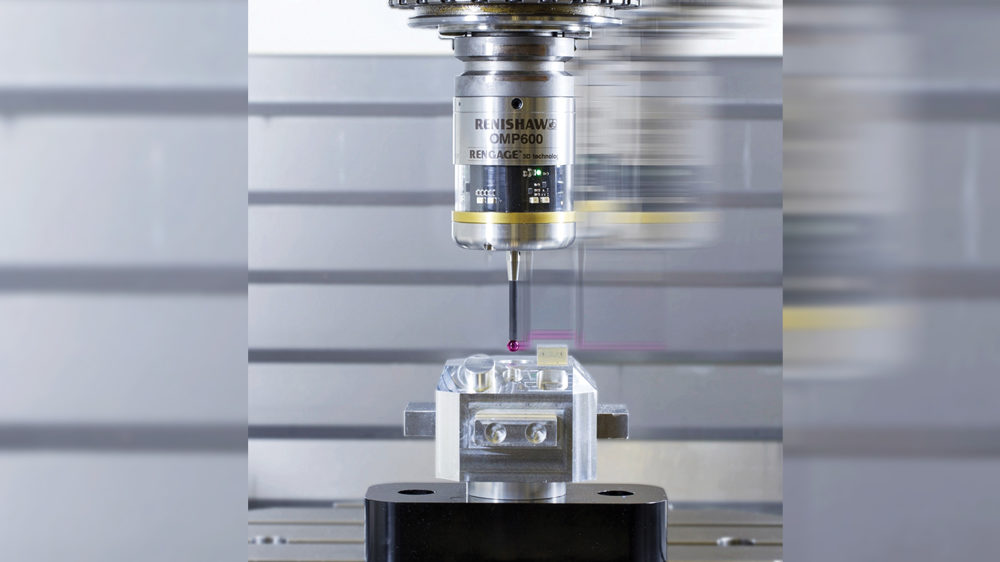

Keeping with the changing era of digital transformation, manufacturing segment is also witnessing reinvention of their own processes through advanced technologies such as digital manufacturing. Digital manufacturing solutions help companies create 3D simulations of plant design and operations thus helping them configure smooth, safe, non-iterative, and non-interfering or hindrance free and seamless manufacturing processes. Right from assembly lines, human ergonomic simulation, robotic simulation, men and machine interactions, to overall plant layout, and many more critical aspects of manufacturing could be defined and analysed virtually in the 3D environment. Digital manufacturing solutions and technologies can help companies configure optimised work flows during the plant layout stage which enables them to enhance the productivity and overall output of the company.

Today the use of 3D printers has also evolved to an extent that these machines are not just used to develop parts for physical product design validation, but in reality are being increasingly used as production machines to build parts for end-use applications. 3D printing makes for an ideal approach for small batch and customised parts development.

The slow pace of technology adoption explained

With the Government of India promoting ‘Make-in-India’ initiative, the industry here has to continue upgrading their infrastructure and capabilities to meet the global standards of engineering and manufacturing excellence. The companies in India are witnessing the changing landscape of manufacturing and have come to realise that they have to adapt themselves as per the changing times by adopting these new technologies and processes or they will not be able to remain competitive. This general awareness is high, but the technology adoption curve in India is generally slower than the developed countries. Big manufacturing companies in India are adopting these technologies, however the use of these solutions has not greatly penetrated among the MSMEs who perceive them as expensive, luxuries for the big companies, and optional, thinking they do not need them and can manage with their existing resources. In their approach, MSMEs are more experience driven rather than opting to leverage new technology.

Smart products for ‘smart factory’

The products offered by DesignTech help companies in conceptualising and building smart factories. Smart factories essentially mean the factories which are automated and which actually take decisions based on some predetermined events. This needs designing and using smart products. Such products are a combination of many technologies like electrical, mechatronics, instrumentation (sensors) embedded systems and software. The range of 3D modelling and simulation solutions offered by DesignTech can help companies design and simulate such systems.

Helps companies leverage digital manufacturing technologies

DesignTech works with many large product design and manufacturing companies and provide them the software tools required for digital designing and manufacturing as well as provide them with product design and engineering services to carry out digital designing and manufacturing. In a way, DesignTech helps companies leverage digital manufacturing technologies to remain at the cutting edge of technology and be globally competitive.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.