Beyond Digitisation

June 29, 2017 5:04 pm

Keeping their aspiration to go global in perspective, Indian companies need to upgrade their operations, develop skill set and a keen look at the learning of the companies set in a global ecosystem.

Dassault Systèmes provides software solutions that help its customers – right from design to execution of a product. Arun Rao, Director, Strategic Operations & Alliances, Dassault Systemes – India shares his opinion on Indian manufacturing sector’s stride towards digitisation.

Digitisation, a journey

Digitisation is no longer a ‘future trend’ – for many companies it is now at the heart of their strategic and research agenda. In today’s age of experience, digital manufacturing and manufacturing operations management (MOM) has emerged as an important tool to cut costs, maintain productivity and achieve manufacturing excellence. With the fast adoption of digital manufacturing and MOM, the dream of making the world a digitally sound place has come closer to reality. With the technology today, companies have the capability to design and test every aspect of the product or service virtually and hence elevate the quality of the services in a cost efficient and precise manner. In this age of experience, new capabilities require businesses to be agile, customer-oriented, well-connected, innovative, efficient, and most importantly aligned with present and future customer needs. Digitisation is not only a development stage, but a journey having various connected objectives. It requires businesses to strive towards continuous improvement and optimisation of business processes.

Digitisation has had a direct impact on the supply chain management. Before digitisation, the supply chain was a series of largely discrete, siloed steps taken through marketing, product development, manufacturing, and distribution, and finally into the hands of the customer. But with the advent of digitisation brings down those walls, and the chain becomes a completely integrated ecosystem that is fully transparent to all the players involved — from the suppliers of raw materials, components, and parts, to the transporters of those supplies and finished goods, and finally to the customers demanding fulfilment. While the digital revolution has already significantly impacted industry, its benefits are yet to be extended to the planet’s 7 billion inhabitants.

Preparedness of Indian manufacturing sector on digitisation

To achieve what we are headed to, Indian companies will need to prominently up their ante with respect to their performance and quality. The primary issue lies in the fact that a wide range of Indian manufacturing companies at present are largely domestic market-focused and are spread across many undifferentiated business models. For establishing a sync with the global parameters of production, Indian manufacturing will have to diversify across broad sectors and across many companies within a particular sector. Most of India’s largest manufacturers cannot return their cost of capital turning into a cause of dampening investment and making it less attractive than its counterparts in competing economies, such as China and Thailand. Keeping their aspiration to go global in perspective, Indian companies need to upgrade their operations, develop skill set and a keen look at the learning of the companies set in a global ecosystem.

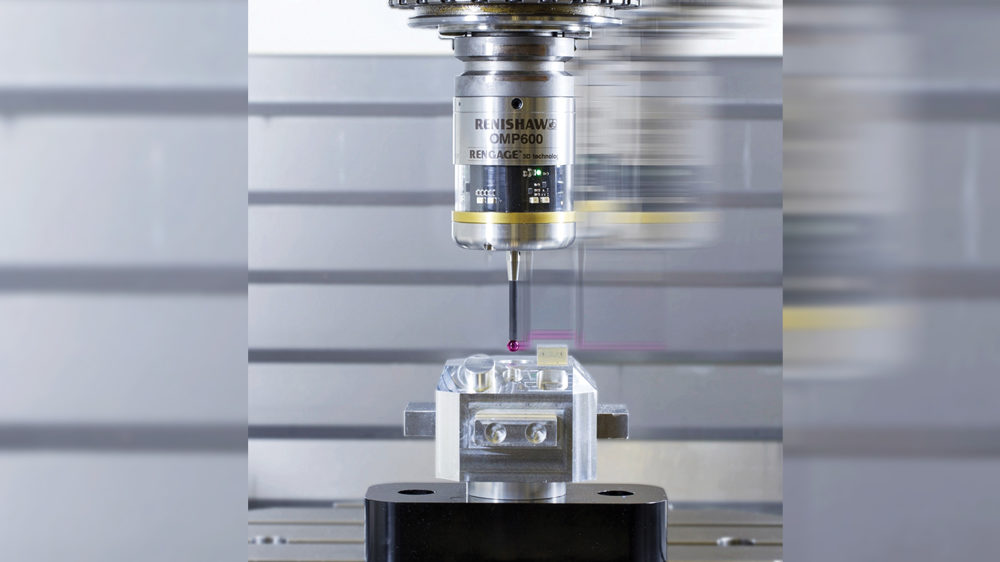

Coupled with 3D printing technologies that could help overcome shortcomings of geometry, digital manufacturing can boost the ‘Make in India’ initiative. Due to the technological adoption in the recent past and the promise that we have shown as a budding economy, global companies like Sony, Samsung, Xiaomi, Hitachi and many more have set up operations in the country. At the same time, a lot of Indian manufacturers are using this technique to cut costs and improving quality by getting it right the first time, which is encouraging for the development of such software programs that are pushing the boundaries of technology further and further only to proudly bring to the forefront – ‘Made in India’.

Providing software and industry solutions for smart factory

Dassault Systemes has been one of the leaders in providing software and industry solutions for ‘Smart Factory’ development. It recently acquired Ortems&Quintiq and folds the company into the 3DEXPERIENCE (specifically DELMIA) platform because it offers power technology to design, simulate control the smart factories of today and the future. Using Dassault solutions, factory managers can streamline the worlds of virtual design and physical production in a Virtual Twin of the actual factory and try out various techniques to make it indeed a smart one. With DELMIA software, manufacturers can quickly absorb the myriad complexities that happen on the manufacturing floor and build out interactive ‘Virtual Twin’ that can deal with the ‘what-if’ scenarios that plague manufacturers. In addition, the solutions enable manufacturers to transform their operations while achieving and sustaining operational excellence. It allows tightly synchronise global manufacturing operations and product supply networks by delivering real-time visibility and control across the enterprise.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.