Spot Welding Robot Market Trends, Development and Growth Opportunities forecast

January 27, 2023 11:15 am

Spot Welding Robot Market size was valued at USD 6.8 Billion in 2021 and is projected to reach USD 15.7 Billion by 2030, growing at a CAGR of 9.5 percent from 2022 to 2030.

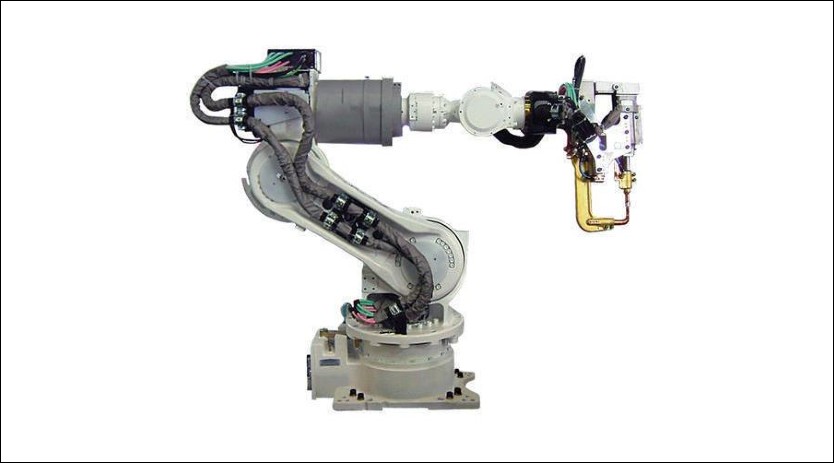

Automated spot welding machines are utilised in the production and design of products. They are managed by PLCs, and the rotating and stretching motions of the robots utilised for shifting are managed by stored producers inside the robots. Robotic spot welders are a productive substitute for mass production that has shorter production cycle times. The manufacturing industry’s increased need for automation and scalability, the rise in demand for spot welding robots due to their many benefits, including the reduction of errors associated with manual spot welding, and the growing adoption of Industry 4.0 are the main factors driving this growth.

A robot that welds metal object pieces together is called a welding robot. Robots used for welding are often automated, meaning they can operate without assistance from a person. They are frequently employed in industrial settings because they may expedite the welding procedure while maintaining a high standard of precision. The rising demand for automation across sectors, the expanding use of robots in industrial processes, and the increased uptake of Industry 40 technologies are all factors contributing to the growth of the welding robot market.

Location welding is a type of electric resistance welding in which two shaped copper alloy electrodes are used to simultaneously clamp the sheets together and concentrate welding current into a small spot. The metal will melt and produce the weld when a strong current is forced through the area. Spot-welding robots are employed in the manufacturing sector for a variety of tasks, including product assembly, fabrication, and packaging.

One of the main end users of welding robots is the automotive industry, which also drives the market. Since a long time ago, welding robot growth has been fueled by the employment of welding robots in this industry to assist cut labour costs and increase productivity, reliability, and quality control over welds. Manufacturers in Europe, where labour costs are high, the workforce is ageing, and there are relatively few skilled welders, are expected to increase their demand for robotic technology due to its benefits, such as improved process efficiency, increased production output, and lower total operating costs.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi