How to optimise milling operations?

October 9, 2017 6:10 pm

An in-depth analysis on how to achieve best performance and economy in milling operations.

Rigidity of structure is most essential

Shorter product cycles and steadily increasing quality requirements combined with equally important demand for economically viable machining is permanently present in the field of milling technology. “In metal cutting process, the rigidity of structure is most essential to achieve demanding performance, stable and longer work life of machine with retained accuracy and quick reacting accessories,” opines Vikas Taneja, Vice President – Marketing, Jyoti CNC Automation Ltd, Rajkot.

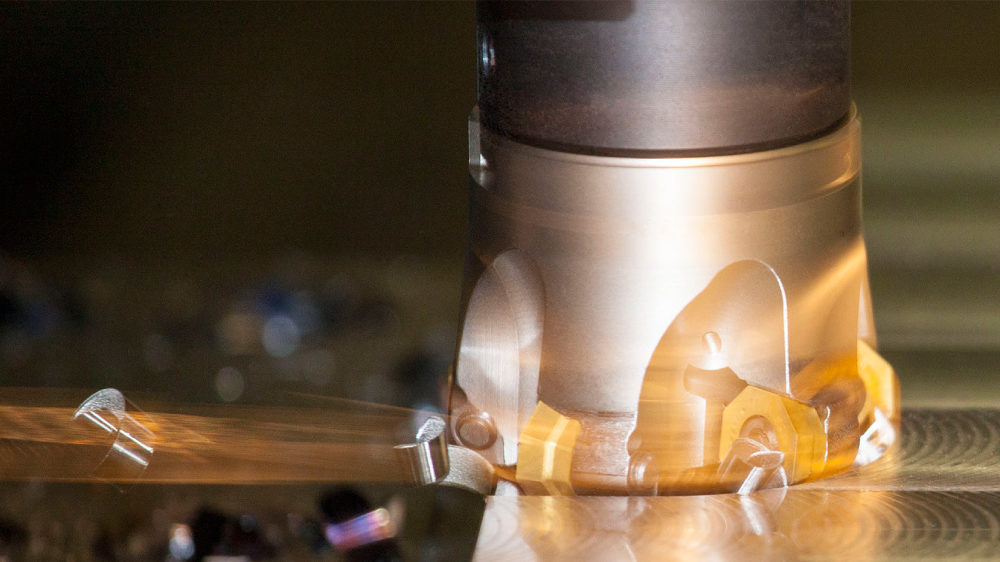

The key of success in milling is as less as vibration on tool and spindle. “We need to have very rigid clamping on spindle as well as rigid fixture which sustain the load of cutting,” reiterates Mahesh Tyagi, Managing Director HELLER India Pvt Ltd.

Nowadays, tools which are running on very high cutting speeds demand a strong base. So the key of success is rigid system. Tyagi acknowledges, “If you have vibration in system then inserts will have no life and whole economics will go down. You can select various grades and coatings from tooling suppliers. Spindle should looks like this, its Heller spindle system.”

Success lies in selecting proper tools

Economic factors are attained by bringing down non-cutting time with rapid active accessories such as rapid movement of axis, fast Automatic Tool Changer (ATC), quick indexing palletisation and automated work handling. High speed and power of spindle with rapid acceleration or deceleration assures desired performance under demanding cutting parameters. According to Taneja, “Proper cutting tool selection considering metallurgy, process parameters and cutting condition would be added advantage to performance and economical operation.”

Efficient and effective chip removal system fulfils the need of uninterrupted machining with reduced operators fatigue. The new concept of tooled up solution includes fixture designing, tooling and cutting parameters selection would assure increase in performance and economy. “Total Productive Maintenance (TPM) is an added feature to modern machine tool building to retain the machine performance for longer time which increases the economic performance. Synchronising tool monitoring system and probes would also reduce possible damage and ideal setting time,” Taneja adds.

Moreover, Gautam K. Ahuja, Managing Director, Dormer Tools India Pvt Ltd observes, “To achieve the best performance and economy in milling, we need to start right from the initial stage – during the finalisation of the machining centre. We need to ensure that the spindle motor of the machine has sufficient power, so that the roughing operation is preferably done in a single pass. We should go for a through coolant spindle, and prefer an HSK taper, for the most rigid connection.”

The next stage to ensure high performance is while designing the fixture. “We should have proper locations and maximum number of supports, to arrest all vibrations. The wall thickness of the fixture and clamps should be sufficiently high, since many times we under-estimate the high forces developed during milling,” Ahuja recommends.

Once we have the right machine and fixture, we need to select the cutter, which is capable of taking the roughing depth in a single pass, and yet have low cutting forces on the spindle, to ensure its longevity. For roughing, Ahuja suggest, the cutter should have medium to close pitch, depending on the material to be cut, to ensure a high feed rate and metal removal rate.

The inserts should be having high multiple edges, for maximum economy. The geometry and grade selection should be done carefully, to withstand high hot temperatures, and still achieve the maximum tool life, at desired parameters. “We should go for through coolant milling cutters which ensure that even at high RPM, the coolant reaches the tip of the inserts, leading to a longer tool life,” Ahuja points out.

Achieving milling economy

In any machining application, economy is strongly linked to performance. It is not possible to delink the two, since the customer’s expectation, invariably, is excellent performance combined with highest value for money.

A significant way in which milling economy is achieved is by producing more number of cutting edges in any insert, says Naveen Vastrad, Senior Manager – Marketing (Products), TaeguTec India. Citing an example, he said, an insert with 2 cutting edges is now effectively replaced for equivalent performance with an insert with 4 cutting edges. Similarly, traditionally 4 cutting edge operations are done faster and more productively by 8 cutting edges; 12 edges have been superseded by 14 cutting edges etc.

“Combined with rake geometry and geometry of TaeguTec grades, we are able to offer best economy and optimised cost per edge advantages to our customers,” claims Vastrad. “Another instance of design advancements facilitating cost optimisation is use of serrated cutting edge in long overhang applications. Also, double-sided positive cutting with shredded geometries in cavity and profile milling where, traditionally, single sided round inserts were in use.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi