GOM conducts 3D metrology for sheet metal forming processes

April 11, 2017 11:09 pm

GOM is a manufacturer that develops, produces and distributes software, machines and systems for industrial and automated 3D coordinate measuring technology and 3D testing.

APM Technologies has been associated with GOM since 1999 selling GOM products in India. The company is headquartered in Delhi with branches in Pune and Bengaluru. The APM team is trained to handle pre-sales selection of scanners, installations and training of users as well as support requirements. The APM facilities include ATOS & TRITOP systems at Delhi, Pune and Bengaluru offering demos and benchmarking. APM has a CAD Centre in Delhi including Pro-E Creo, Unigraphics, Catia and Solidworks.

GOM is conducting international workshops on 3D metrology in sheet metal forming at 23 locations across the world between January and April. Industrial companies share their experiences and the GOM network transfers process and metrology knowledge in 15 countries. In India it will be held be on 12th April at Hotel Sayaji, Pune.

GOM workshops are an industrial meeting platform for design engineers, tool makers as well as specialists from R&D, production, and quality assurance. They provide insight into the use of optical 3D metro-logy in the sheet metal forming industry. Leading industrial companies present examples from their day-to-day practice.

They show how integrating optical measuring systems into the entire process chain helps them shorten development times, improve production workflows, and thus enhance the company’s profitability. Alongside these user experiences, the GOM Team stages live presentations to introduce the latest developments in 3D metrology as well as in measurement and inspection software.

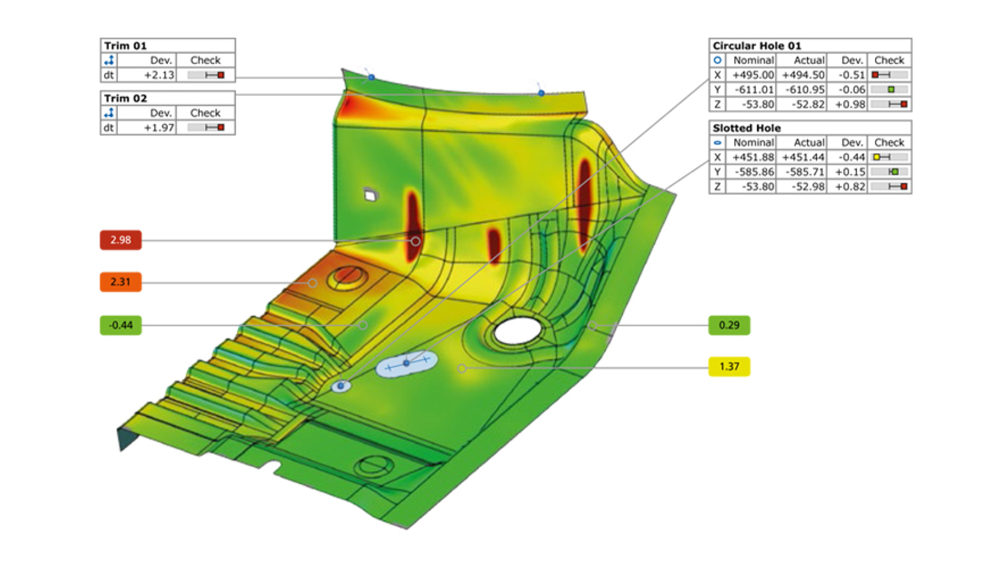

Measuring systems from GOM are used in stamping, bending, drawing, pressing, and forming process chains to guarantee consistent quality assurance: from determining the sheet metal properties, via accelerating tool-try-out and first article inspection, up to series-accompanying production control and trend analysis.

GOM systems provide precise material parameters by determining the Forming Limit Curve (FLC) for design and simulation. During try-out, sheet metal parts are checked for shape and dimension as well as material defects: component geometry, spring-back, trimming, hole patterns, material thickness, and forming limit analysis. For the series-accompanying quality control, all measurement and inspection processes are automated

The workshop is free but pre-registration is recommended due to limited seats

For registration, visit: www.gom-workshop.com/in, or www.whitelightscanning.com/news/list/1

Call on +91-11-41631416 or email at conference@apmtech.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi