Digital microscopes replace traditional magnification tools in quality control

January 14, 2019 2:48 pm

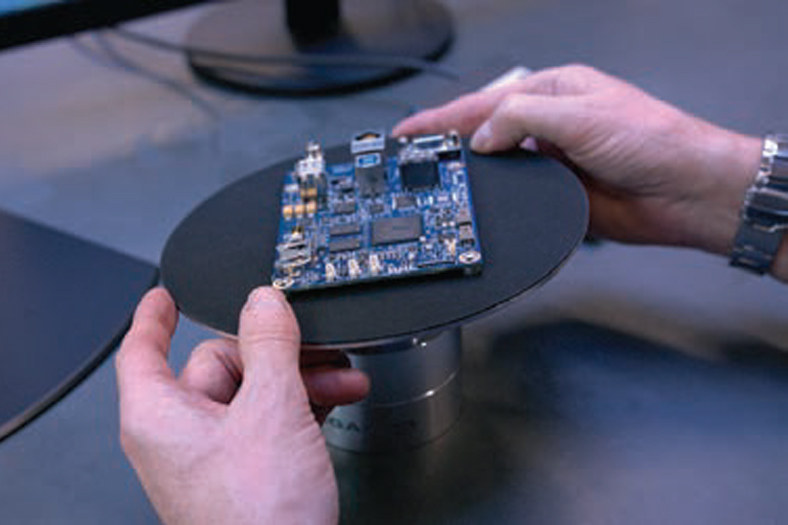

Using a digital microscope instead of traditional magnification tools to repair and/or rework defective boards will improve the operator’s user experience and pave the way for more efficient quality control thanks to the bigger working area and real time image display.

Once a printed circuit board has been identified as faulty during quality control, repairing and reworking will most likely include hand soldering. However, due to the miniaturisation of components in, e.g. smart phones and tablets, traditional tools such as magnification lamps and optical microscopes become insufficient or inexpedient.

Digital microscopes replace traditional magnification tools

Today, higher magnification levels than previously are needed when hand soldering ICs and capacitors due to the increasingly smaller components. However, many operators find that magnifying lamps are no longer able to provide the required magnification levels. Moreover, optical microscopes, usually considered the alternative to magnifying lamps, have a small field of view, creating a limited working area and thus making it difficult for the operator to work under. A digital microscope will also improve cooperation between colleagues by looking at a shared monitor.

Repair and rework in real time

Using a digital microscope to repair and rework defective boards will not only provide high magnification levels and increase usability, making quality control easier for the operator and thus enabling them to work more efficiently. A digital microscope will also display a live image of what happens beneath the camera with no delay, eliminating moments of irritation and improving the quality control working conditions.

Improved ergonomics and hand-eye coordination

With a digital microscope, the user can see the magnified object on a monitor, alleviating the operators of unnecessary neck pains and headaches as they are no longer bending their necks to look through an ocular or magnifying lamp. Cases show that the elimination of straining work postures leads to less sick leave and staff infirmities.

With the help of an inline flex arm, the operator can also stand directly in front of the camera and object under the microscope. This further improves the ergonomics and hand-eye coordination of the operator and thus paves the way for more efficient rework.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi