Communicative smart tooling for precision machining

August 7, 2019 3:14 pm

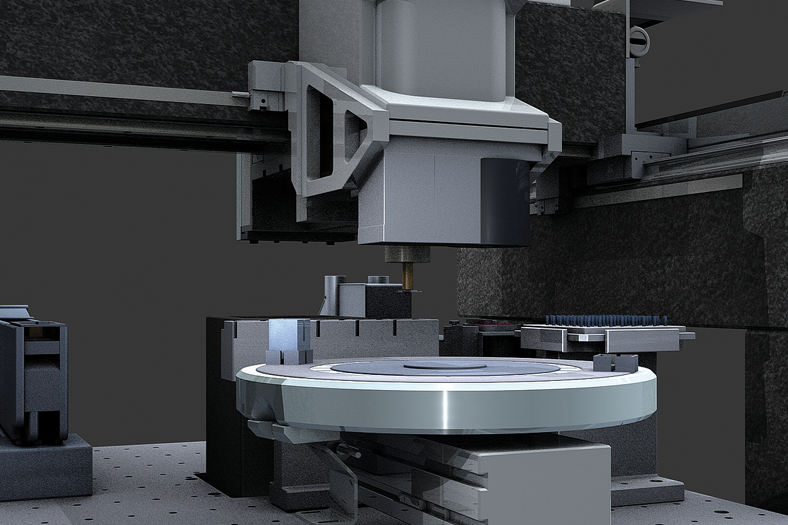

With the context of Industry 4.0, smart tooling and smart machining have become increasingly popular for tremendous potential towards next generation precision machining technologies. Industry experts define the role performed by smart tools, especially in agile manufacturing.

Machine tool industry in India has advanced significantly, in hardware and software applications. The future includes automation of processes into manufacturing and engineering sectors. Reduced manual intervention in process control using machine tool control system and smart tooling would be the key to optimise cost, reduce scrap and improved machine utilisation.

The role of smart tooling in the machine tool industry

A crucial function of smart tooling is the on-line acquisition of process relevant data during the machining of work pieces leading to higher efficiency and more reliability. Dr. Uwe Schleinkofer, Head of R&D Cutting Tools – CERATIZIT GROUP states, “This data acquisition can take place in the cutting tool, the processing area close to the machining process, or in the machining centre. Therefore, the role of smart tooling is to combine conventional tools with information and communication technologies.”

On one hand, this allows remotely to control the tool behaviour and initiate preventive actions (e.g. optimise cutting parameters, changing tools, stop the process) during the machining process. On the other hand, it is possible to link tools, machines, and manufacturing lines together to a network, creating a highly efficient process structure by analysing and rating the measured data. Dr Schleinkofer says, “The extremely high number of influencing parameters in a machining process must be addressed and prioritised to create tailor-made actions, which can significantly support the machine operators in technical applications. Looking forward, we will probably see an even greater focus on the role of smart tooling in the machine tool industry.”

With the context of Industry 4.0, smart tooling and smart machining have become increasingly popular for tremendous potential towards next generation precision machining technologies. In machining industry to come at par with dynamics of machinery in order to process variations and complexity, it is important that we carry out processes in ‘proactive’ manner. Maulik Patel, Executive Director, SLTL Group says, “With increase in the demand of high precision components, it has become a little difficult operate and measure components with existing conventional tools. To increase the performance, precision and efficiency of the machining and tooling we must progress in the direction to quickly integrate smart tooling into our existing and future machines.”

Smart tools for agile manufacturing

Smart tools combine a tool with an information technology system. But more broadly speaking, a smart combination of substrate, coating, tool design, and related application data can be considered as a smart tool for a highly effective machining process as well.

According to Dr Schleinkofer online process monitoring tools which control and predict the machining process, currently, are a big trend in the machine tool industry. One of these products, Dr Schleinkofer says is the CERATIZIT ToolScope, which can be installed on a big variety of machining centres. ToolScope monitors cutting relevant data during the process and can react in an appropriate/predefined way if necessary. Furthermore, active tool systems like the KOMET KomTronic systems deliver enormous benefits – both economic and qualitative.”

Recent research projects focus on the acquisition of data inside the cutting tool or the related adapter. The smart analysis of this data is one key aspect to draw the right conclusions for an agile manufacturing process. Considering all these aspects, smart tooling could lead to a big data approach in which a complex cutting process can be predicted and simulated without creating one single chip.

According to Patel, “I think when we talk about ‘agile manufacturing’, we are considering improving and adjusting overall company’s operations from manufacturing to processes and quality standards, according to customer demands.” Smart tools like Industry 4.0 and Internet of Things (IoT) have been in consideration. With these tools integrated in the tooling and machining systems, it becomes easy to attain precision and dynamic operations to execute complex operations which was time consuming and difficult with existing conventional systems. Also, Augmented Reality (AR), Artificial Intelligence (AI) and machine learning are also the technologies that industry is trying to find substantial use of.

“Online process monitoring tools, controlling and predicting the machining process, is the current biggest trend in the machine tool industry”

Dr. Uwe Schleinkofer, Head of R&D Cutting Tools – CERATIZIT GROUP

“With smart tools integrated in the tooling and machining systems, it becomes easy to attain precision and dynamic operations to execute complex operations”

Maulik Patel, Executive Director, SLTL Group

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi