Shifting Gear

May 14, 2018 12:50 pm

A report on the changing dynamics in Gears, Motors and Transmission segment.

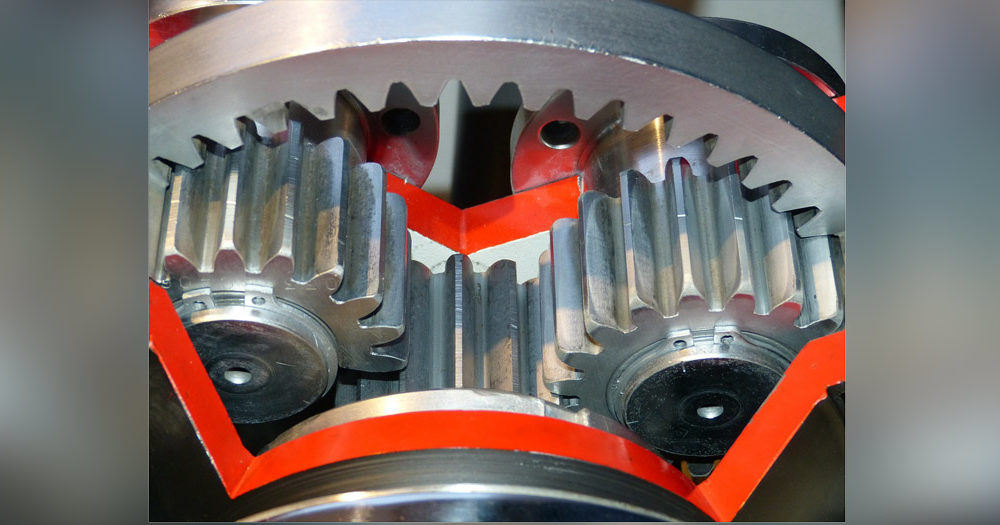

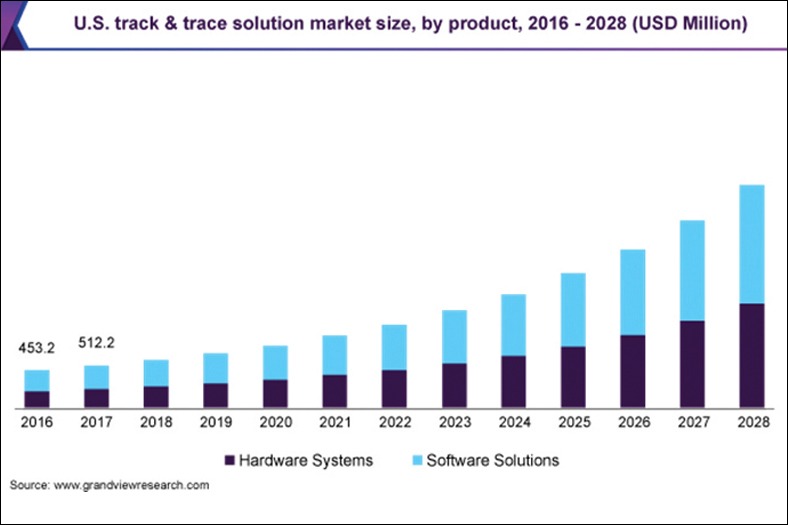

The global gearboxes and gear motors market is witnessing steady growth, augmented by the adoption of more energy-efficient gearboxes and gear motors, investment in wind energy, material handling, food and beverages, and replacement demand from developed regions. Successful companies will be those that continuously enhance the power transmission efficiencies of their gear systems, focus on vibrant market segments, and develop and expand direct drive systems.

According to Frost & Sullivan’s research, Global Gearboxes and Gear Motors Market, Forecast to 2021, finds that gearboxes in the power rating segment 500kW to 10MW are expected to be the fastest growing segment due to significant share of this type of gearbox in wind turbines. The study provides a comprehensive understanding of market trends, forecasts, opportunities and challenges across 16 end-user segments and four geographic regions. Four major gear technologies across five gear power ratings are also assessed. A competitive landscape for major players such as Siemens AG, Sew-Eurodrive, China High Speed Transmission Equipment Group Co Ltd, Sumitomo Heavy Industries, Chongqing Gearbox Group, Rexnord Corporation, Nabtesco Corporation, and others is provided.

“The renewable energy segment provides opportunities for motors vendors that have significant presence and capability in supplying gearboxes or gear motors of power ratings up to 7.5kW and 7.5kW to 75kW for positioning applications,” said Frost & Sullivan Mechanical Power Transmission Research Analyst Krishnan Raman. “Typical applications are in yaw and pitch control of wind turbines and in solar tracking for repositioning of solar panels.”

Regional trends and developments in the global gearbox and gear motors market include:

• Asia-Pacific region witnessing significant growth with strong demand from applications in discrete manufacturing, such as automobile manufacturing, machine tools, packaging, semiconductor electronics manufacturing, and wind power generation segments;

• Fast growth in North America due to return of manufacturing to the United States and growing investment in the material handling, oil and gas, and chemical industries;

• North America end-user preference for worm gearboxes with cast iron casing;

• Gearbox and gear motors manufacturers supplying bevel and helical gear motors with low backlash in the output power range of less than 7.5kW to gain significant sales opportunities in the Asia-Pacific region;

• Europe, Middle East, and Africa region to remain the largest market for gearboxes and gear motors;

• Increase in sales of gearboxes and gear motors in Europe due to large original equipment manufacturers that export significant share of machinery to regions such as Asia, North America, and Latin America;

• Brazil coming out of a recession in the medium term will bolster Latin America’s growth potential; and Mexico experiencing moderate growth.

High energy-efficient drives

M M Nanda, CEO, Gear Division Elecon Engineerign Co Ltd, Says, Nowadays, concept of high efficient drives is most popular in terms of saving energy and reducing operational cost. Gear drives are now changing from conventional worm or open gearing to high efficient helical or planetary type. Also majority of new plants in core sector like cement, steel, sugar, power etc. Are coming up with higher and higher production capacities, which demanding high torque gearboxes like planetary type.”

Elecon have already developed such high torque planetary gearboxes suitable to various applications of cement, power, sugar and steel industries. Also Elecon have expanded manufacturing and testing capabilities to fulfil such requirements.

For all small and medium drives such as applications with power ranging up to 15 KW and RPM in the range of 200-25, industry have started using geared motor instead of gearboxes. Nanda informs, “Since, Elecon have gear motor manufacturing company within group name Radicon PowerBuild, we are able to cater this requirement also. Worm Gearboxes of less than 3 inch centre distance size are replaced with light weight aluminium series gearbox and Geared motors. Since our group company Elecon peripherals deals with aluminium series gearboxes and geared motor, we are able to cater this requirement too.”

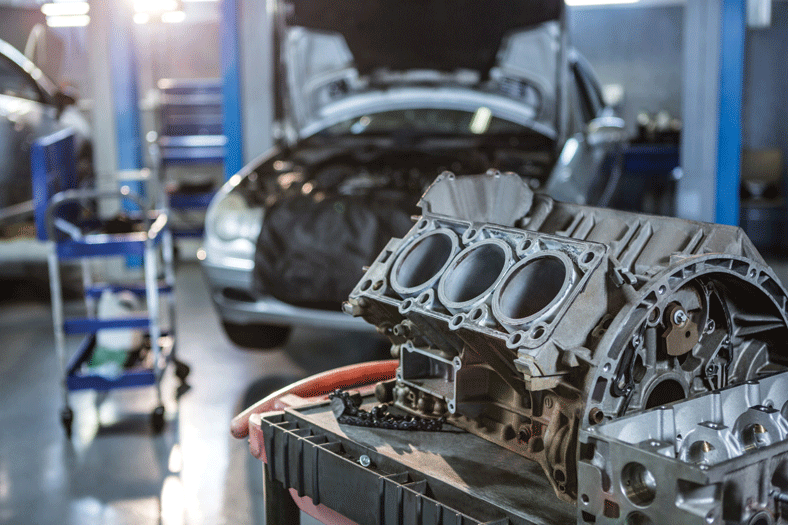

Dynamics of transmission

Anuragam Vatsa, Plant Head – Pant Nagar Plant, RSB Transmissions (I) Ltd says, “The transmission component forms a vital part of a vehicle’s powertrain, as it involves transfer of engine power to wheels. There is always a concerted effort to reduce power losses in the transmission, while trying to attain efficiency optimally. An efficient transmission system helps to enhance fuel economy and ensure the power produced by the engine actually gets to the wheels, while keeping the acceleration and top speed thereby maximising acceleration and higher speed.”

Conventionally, transmission consists of gears that move and slot into position when they are engaged to deliver desired torque to the drive shaft of the vehicle. Traditionally, it makes use of a manually operated clutch, which disengages gears temporarily from the engine and re-engages the next chosen cog as smoothly and seamlessly as possible. Manual transmission has been in place for decades, especially in India, as it provides a combination of lower costs and better fuel economy.

Vatsa informs, “General Motors was one of the first companies to market automatic transmission in their vehicles, doing away with manual engagement of clutch. The system combined the hydraulic operation of a planetary gear box with a fluid coupling instead of friction clutch, which do away with need for de-clutching. The transmission had four forward speeds and a reverse, and also incorporated a parking pawl, which was engaged when the gearshift selector was replaced on the reverse while the engine is off.”

AMT, DCT and CVT

With advent of global R&D initiatives over a period of time, RSB Transmissions have assorted automatic transmissions, including traditional automatic transmission, the Automated Manual Transmission (AMT), Dual Clutch Automatic Transmission (DCT) and Continual Variable Transmission (CVT), which are extended, besides passenger vehicles, to various types of commercial and high-way vehicles.

While Conventional Automatic Transmission (AT) remains still popular and common globally since it makes use of a torque converter to transfer the power generated by the engine to the gearbox. Vatsa opines, “They also use gears that are similar to those used in a manual transmission, but the gears are engaged in a different manner. The torque converter is the device that changes gears in a traditional AT system. Impeller, turbine and stator, which go into torque converter, are filled with fluid to ease the lock or unlock with multiple clutches to control the planetary gears of transmission.”

A well-engineered AT delivers power in a smooth, linear manner and with the doze of modern-day electronics, can be operated in different driving modes (for example, ‘sport’ or ‘eco’) that alter shift patterns, thereby providing either a more dynamic driving experience or improved fuel economy. Since, the AT does not have a clutch pedal; it also makes driving easier and is hence especially suitable for driving in the city, where dense traffic is often the norm. Nissan and GM were working for reduction in energy losses in the fuel cycle two and four stroke engine through Variable Valve Timing.

DCT (Dual Clutch Transmission), which are used in high-end cars, are technically advanced and provide the best user experience as it uses two separate clutches arranged concentrically with one clutch each dedicated to odd and even gears respectively. This provides very fast gear shift speeds, since the next gear is already pre-selected and engaged by the time the previous one is released.

What is the future?

With the variants in AMT, CVT and DCT, automatic transmission looks taking a lead in popularity replacing conventional ATs with premium car buyers and in entry level cars. With raising traffic congestion across the cities, AMTs are now preferred over MT due to their sheer ease of operation, besides it works better with sportier and powerful cars.

With the development of new age AMT, especially in Indian market, which offers all the convenience of conventional ATs at an affordable price, without hurting the fuel efficiency. The future of transmission will get confined to AT due to dynamic performance, seamless and smooth operation, removing fatigue of conventional MTs.

Nowadays, concept of high efficient drives is most popular in terms of saving energy and reducing operational cost.

M M Nanda, CEO, Gear Division Elecon Engineerign Co Ltd

An efficient transmission system helps to enhance fuel economy and ensure the power produced by the engine actually gets to the wheels.

Anuragam Vatsa, Plant Head -Pant Nagar Plant, RSB Transmissions (I) Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi