Process automation: Revolutionising manufacturing sector

July 14, 2018 11:20 am

Systems in the processing industry are often operated for decades requiring constant rebuilding, expansion and modernisation. Aspirations to make processes more efficient are as old as the processing industry itself. Let’s take a look at how process automation impact productivity.

Process automation is used to automatically control a process such as chemical, oil refineries, paper factories and or any production factories. The process automation often uses interconnected sensors, controllers, operator terminals and actuators to control the process. Using process automation, companies take out the complex, most redundant steps from their processes and streamline them for simplicity to increase productivity.

Efficient and safe operating conditions

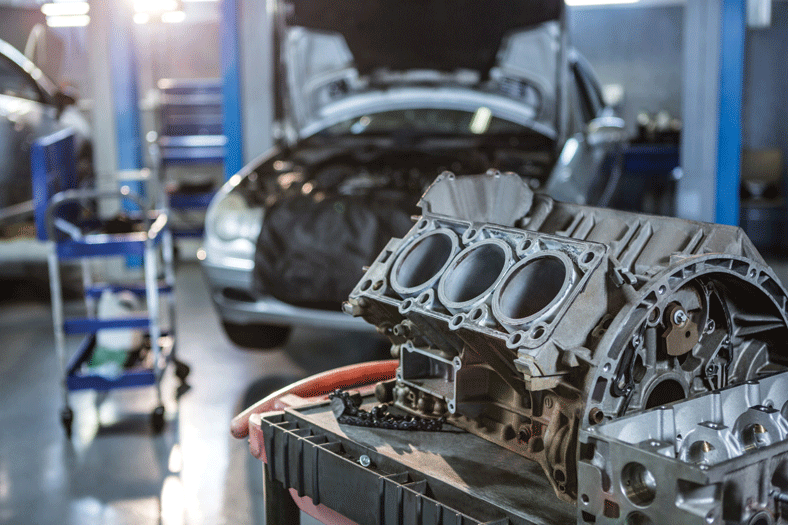

In the absence of process automation, plant operators have to physically monitor performance values and the quality of outputs to determine the best settings on which to run the production equipment. Maintenance is carried out at set intervals. This generally results in operational inefficiency and unsafe operating conditions. Varun Arora, National Sales Manager, Exor India explains, “Process automation simplifies this with the help of sensors at thousands of spots around the plant that collect data on temperatures, pressures, flows and so on. The information is stored and analysed on a computer and the entire plant and each piece of production equipment can be monitored on a large screen in a control room. Plant operating settings are then automatically adjusted to achieve the optimum production. Plant operators can manually override the process automation systems when necessary.”

Factory owners want their equipment to deliver the highest output with as little production cost as possible. In many industries, including oil, gas and petrochemicals, energy costs can represent 30-50 per cent of the total production cost. “In process automation, the software and controls regulate equipment to run at the optimum speed that requires the least energy. They also ensure the consistency of quality, meaning less energy is wasted producing products that turn out to be defective; they also forecast when maintenance is needed so less time and energy is spent stopping and restarting equipment for routine inspections. While these advantages are still a major draw for many businesses, the

focus of decision makers are now seeking solutions to make their processes safer, flexible and more accurate,” says Arora.

Increasing productivity and profits

Productivity is crucial to gain a sustainable advantage over competitors and increasing a foothold in the market. Rockwell Automation informs, “Manufacturing sector has been undergoing a revolutionary phase all over the world. Increase in demand for consumer goods has motivated manufacturers to deploy methods that can increase productivity and make end product available in the market as quickly as possible. Increase in efficiency and smart manufacturing processes have the potential to bring in greater profits and increased opportunities.”

From production, to employees and ultimately the consumer, automation encourages a far more productive manufacturing process when compared to manual production lines. Every manufacturing and production facility faces individual challenges that are unique to their business and market. Rockwell Automation has worked with companies of all sizes to find sustainable solutions that can be implemented in real-time.

Automation in the manufacturing sector is significant for the following reasons:

• Less manual delays: It improves the quality by avoiding manual error and improves the quality of product and enhances productivity.

• Manufacturing data: Automation can provide useful data of the machines which increases the possibility of analysing the cause of low or poor productivity.

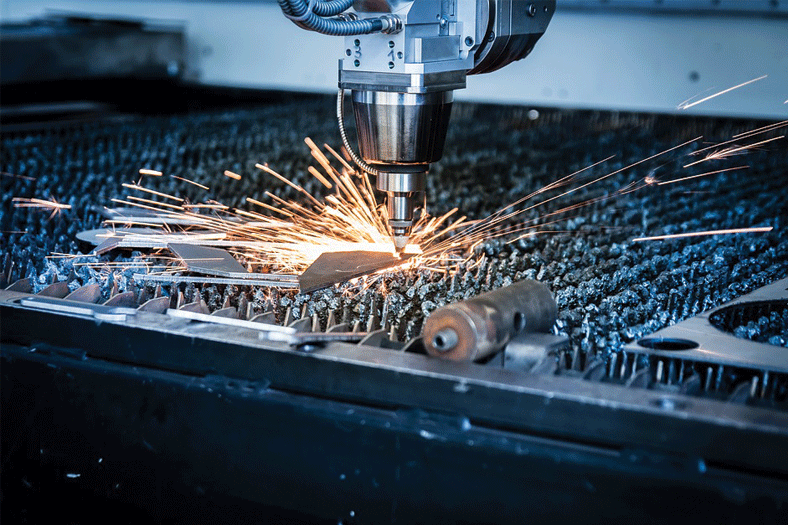

• Optimal machine efficiency: Rather than spread elements of the production process across multiple machines or devices, automation allows one machine to perform an array of different tasks. Without the need to transfer product parts from one machine to another and with more accuracy gained, a larger number of units can be produced within the same period.

• Management and supervision: Similar to how workers can be moved away from repetitive tasks into areas that reflect and encourage skill development, there is a positive effect felt with the management staff. Rather than spending more time micro-managing, automation allows managers to be more creative with their resources.

Increasing efficiency and reliability of assets

Process control is now operated under management systems designed to ensure effective operation and follow appropriate production schedules. The control systems make decisions in real time and also within the time-constant of the process being controlled. Productivity is ensured by process control systems by managing not only the production management systems but also helps in making decisions on human schedules including the transactional decision-making, in case of batch process control. As the sophistication of process management and control systems has increased, the efficiency of industrial plants got steadily improved by pushing hard the process control equipment for maximum capacity utilisation which sometimes are able to exceed even the designed capacity. Mukesh Thakur, Asst. Manager, S&M, Finder India Pvt Ltd observes, “Process engineers are now designing innovative process control solutions to implement safety control systems and asset management systems to ensure the thresholds are maintained. Process engineering technology is now providing the solutions to implement more advanced maintenance techniques that improve asset reliability, including reliability control systems. The real result of a process control system is seen when the net results of process, safety, and reliability are able to realise the ultimate objective, maximising operational profitability, safely and reliably.”

Over the years, considerable advancements have been made as process control systems evolved from feedback control to feed forward control to multivariable predictive control. Whereas the modern day process control systems are now evolving in such a manner that they ensure the management decisions are being made in a coordinated and profit-generating manner. When designing the optimal control and management system, it is helpful to understand how industrial process control envelops the real-time process and logic control to maximise the efficiency of industrial assets. With real-time process data on the one hand and strict transactional business information on the other, manufacturers are beginning to see the value in integrating process control and business software such as Enterprise Resource Planning (ERP) with control systems such as Supervisory Control and Data Acquisition (SCADA).

Automation: Advantage for process industry

Rajeev Ranjan, Assistant General Manager, Process Business, WAGO Pvt Ltd said, “The digital transformation of the economy creates new possibilities for more advantageous configurations in processing through numerous innovative approaches and technologies. A consensus has been reached that machines must communicate with each other in order to function with maximum efficiency. The Internet of Things (IoT) is the new reality even if it continues to be interpreted and implemented in different ways. Data has now become one of the most important assets to any industry that can be collected, evaluated and used at different levels.”

Process industry can take full advantage of automation with the use of IIoT and translate these advantages to achieve operation excellence in following ways. Standardisation can increase efficiency and influence cost reductions. This happens in the form of concepts that unify function blocks, interfaces and protocols for automating machines and systems. For example, leading oil companies already rely on established programming standards. Every single step in software engineering is documented with incredible accuracy and codified so the same program modules can be used everytime. Uniform interfaces between different systems reduce the failure rate during both the design phase and actual operation, while increasing system availability.

In the context of batch size, fluctuating volumes and ever-shifting regional sales markets, companies must have manufacturing processes that are universal, mobile, scalable, modular and compatible. In the processing systems for oil and gas extraction or in the pharmaceutical and chemical industries, the primary focus during design is on flexible production. Within these sectors, processes, here, have to be adapted more quickly than within the oil industry.

Major impacts of factory automation

According to Ninad Deshpande, Head- Marketing, B&R Industrial Automation, “Initially, productivity from the manufacturing unit’s point of view was the sole responsibility of a machine, which eventually led to something like islands of automation within a single factory or even within a single line. Thus, to improve parameters of efficiency, productivity or reliability these manufacturing units needed to talk with not one but several machine builders. Soon, they realised that this approach needed immense effort and, today, this ideology no longer holds ground, with manufacturing units looking at factory automation solutions for enhancing availability, productivity, efficiency, reliability and quality.”

Deshpande informs, “Factory automation solutions help in acquiring data from field and various machines, bringing it in a central system without modifying the program of the running system. This data is then effectively used to convert into valuable information, which provides a deeper insight into operations of the plant. The overall equipment effectiveness (OEE) or even the effectiveness of the entire line can be calculated with ease. This provides managements with real-time information, trends, reports of plant availability, productivity and quality at the click of a button from anywhere across the globe. These systems also help in reducing losses and wastages in the factory. Management, based on these reports and trends, can identify areas of improvement and losses in order to take necessary actions. As these are reported in real-time, the decision-making is quicker and precise. In addition, factory automations capability of providing open source connectivity using OPC UA to the upper IT layers such as MES / ERP provides a seamless vertical connectivity. “

APROL, Process and Factory Automation Solutions from B&R, provides factories and manufacturing units with such solutions, which also integrate predictive maintenance and energy monitoring solutions in the same system. The company has helped factories not only globally but also, in India, to reduce wastages, losses and increase equipment effectiveness, productivity, availability and quality.

In process automation, the software and controls regulate equipment to run at the optimum speed that requires the least energy.

Varun Arora, National Sales Manager, Exor India

Process engineering technology is now providing the solutions to implement more advanced maintenance techniques.

Mukesh Thakur, Asst. Manager – S & M, Finder India Pvt Ltd

The digital transformation of the economy creates new possibilities for more advantageous configurations in processing through numerous innovative approaches and technologies.

Rajeev Ranjan, Assistant General Manager, Process Business, WAGO Pvt Ltd

Factory automation solutions help in acquiring data from field and various machines bringing it in a central system without modifying the program of the running system.

Ninad Deshpande, Head- Marketing, B&R Industrial Automation+

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi