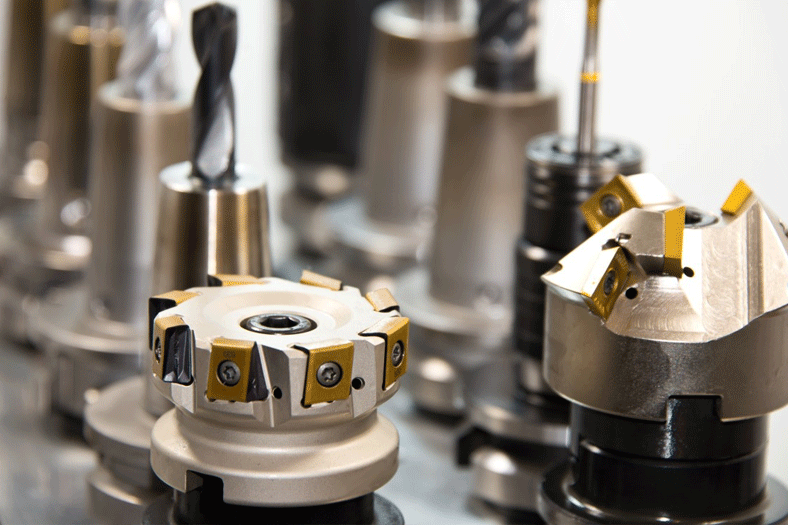

Investments in R&D transforming machine tools industry

January 9, 2020 2:40 pm

Machine tools industry in India is gearing up to be one of the world’s top five machine tools manufacturing countries in the world in next seven years; it is revisiting its capabilities and adding new products and solutions to meet cardinal demand. Industries are investing in R&D and innovation for developing sophisticated and high-precision technology to meet the requirements of India finding lucrative business overseas.

Role of machine tools in “Make in India”

Machine tools industry is considered to be the “mother industry” for all manufacturing industries. Without a powerful machine tool industry, manufacturing excellence cannot be achieved. Government of India floated the “Make in India” initiative with a vision to make the country a global manufacturing hub. The machine tools industry is immensely contributing to the initiative by making the machines required for the manufacturing sector, including major ones such as automobiles, defence, railways, plastic machinery, white goods, and many more.

Machine tools industry has come a long way, where previous year’s import was 70 percent and only the rest 30 percent were Indian machines. This year’s ratio has changed to 50:50. This indicates the growth of the machine tools manufacturers.

Government is providing some assistance for R&D of machine tools, but this needs be stepped up. This will go a long way in aiding the “Make in India” initiative. It’s a long process to invent new technologies. Acquiring them or collaborating with foreign partners or taking over foreign companies is a faster way of doing it. Government should encourage such activities by supporting financially or subsidising such machine tool builders.

Ramesh TK, MD and CEO, Micromatic Machine Tools confidently says, “Consequently, via privatisation, Make in India will get a boost, new manufacturing technology will come into the country and also appropriate technology in this area will develop with the help of joint ventures and tie-ups. Specifically, tier I and tier II will have to make a substantial investment, which will thereby help the machine tool sector.”

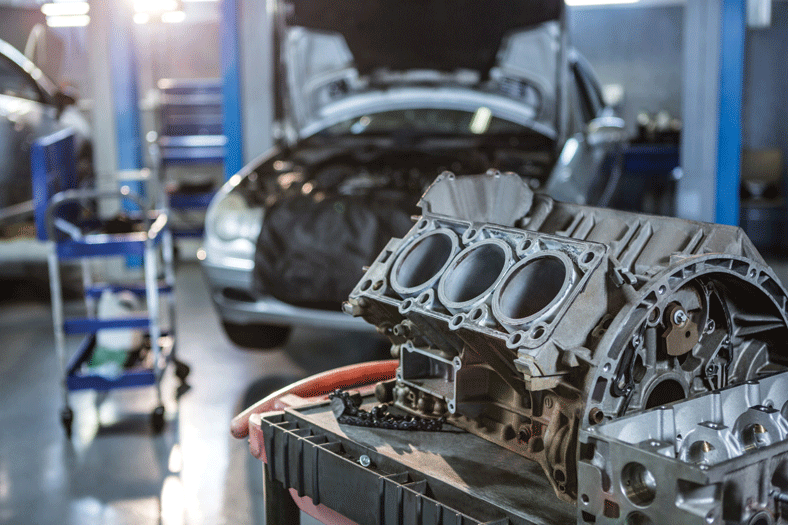

Machine tools companies will have to devise new processes which will be necessary to manufacture the new specifications on the part drawings that will come due to BS6 emission norms. E.g., the finish level and geometric accuracies on the engine and transmission shafts will be much higher and different than previous levels. “Grind Master has experience on working on such higher levels of finishing since we worked on such jobs from global auto OEMs outside India. Another thing is we need to handhold other companies including all the machine builders and end product manufacturers for developing new technologies. This will really make the machine tool industry grow in positive way and make “Make in India” a grand success,” concludes Mohini Kelkar.

Challenges to cater precise requirements

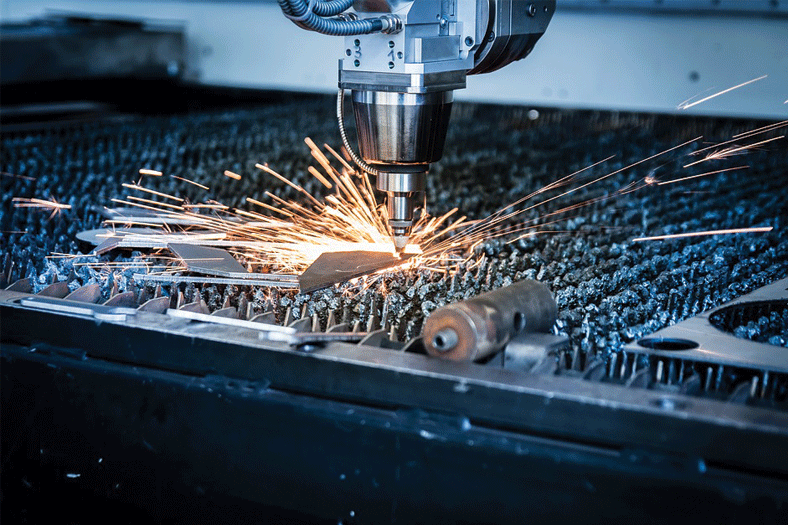

The challenges faced by the Indian machine tool builders are countless. According to Mohini Kelkar of Grind Master Machines, “The list of challenges is long, but the main challenge in front of us is technology gap. There is clear-cut technology gap in terms of machines as well as processes. There are cases where sourcing of several items for regular use in defence sector can be sourced from MSMEs in India. It is also a government mandate to do so; however in practice, it is not happening.”

The materials or components which are required to be machined and processed in these sectors are much different than those in the engineering and automobile sector, for example, special alloys, titanium, special composites. All such materials need different processing methods. Here is the gap which we have to bridge.

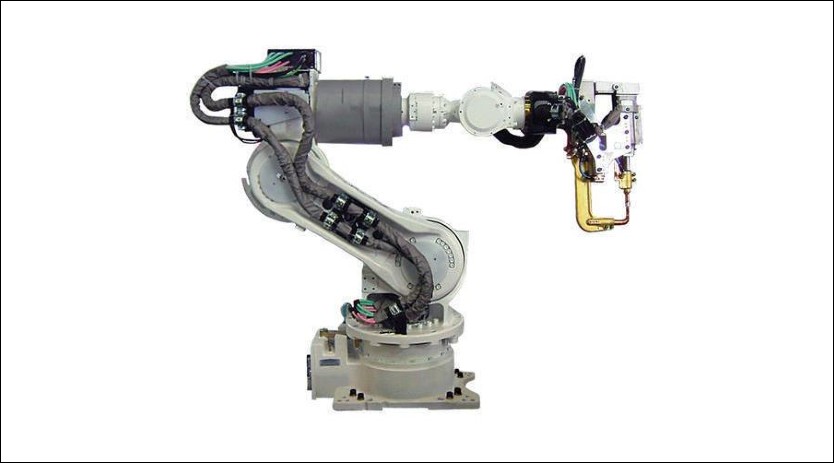

Private companies will be able to innovate and produce defence equipment faster as well as better in the near future. Announcement of the SP programme will create an efficient supply chain that involves tier II and tier III companies to be involved in the manufacturing process. Vineet Seth, Managing Director – South Asia and Middle East, Mastercam APAC says, “It is a known fact that we (India) are the largest importer of defence equipment (arms). It is no doubt a certainty that Make in India opportunities will increase significantly, as a result of this decision. Our dependence on imports and supply delays of the past will be overcome with this initiative.”

Major challenges are faced when handling and processing such materials. The machine tool builders constantly feel pressurised to stay updated in the market; the need to invent and build new machines and new tools which will be suitable for these components. The next challenge is precision which demanded by these sectors can’t be achieved by the current range of machines tools made in India. We need to build high quality machines by high quality workmanship. Many times, the processes such as deburring are neglected but in these sectors, even these processes matter a lot.

The impending technology gap and transfer of technology In terms of manufacturing technology, we are a mature nation. We have access to the best manufacturing technology in the world through companies that now have direct presence in the country. One of the key challenges, however, in the Indian industry scenario is that technology is not easily shared. But another issue to address is that we are far behind on the technology front compared to our international counterparts.

Moving from the current BS4 to BS6 will most certainly entail significant changes to the manufacturing process of each platform for Automotive OEMs.

Vineet Seth, Managing Director – South Asia & Middle East, Mastercam APAC

The precision challenge demanded by the sectors can’t be achieved by the current range of machines tools made in India.

Mohini Kelkar, Director – Sales & Marketing, Grind Master Machines Pvt. Ltd.

Tier I and tier II companies will have to make a substantial investment to help the machine tool sector.

Ramesh TK, MD and CEO, Micromatic Machine Tools

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi