Industry 4.0 drives laser technology growth

March 2, 2020 2:28 pm

Industry 4.0 is currently the biggest trend that is impacting every sphere of manufacturing. Here we discuss the growth of laser technology due to the advent of Industry 4.0.

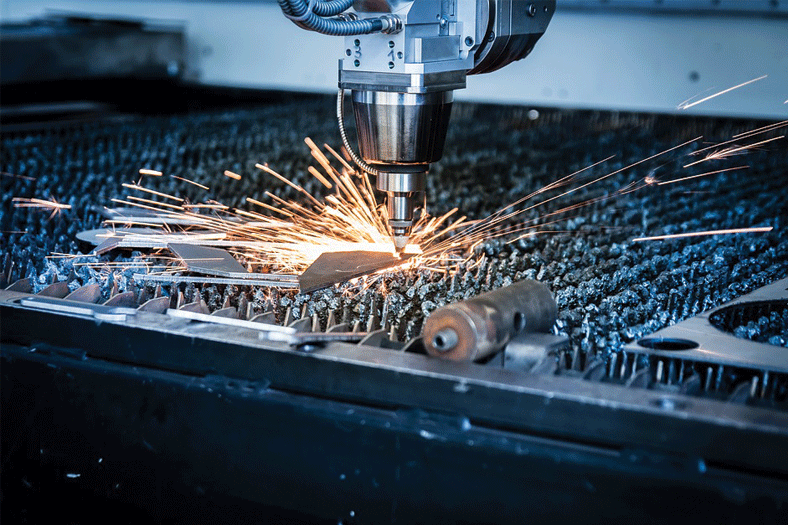

The demand for fibre laser cutting technology is growing very rapidly. Five years ago, the sell rate was around 50-60 fibre laser cutting machines in India, whereas today, it is around 2,000 machines. This multifold increase can be attributed to the fact that manufacturing needs to be flexible, as products become obsolete in 6-8 months. So, OEMs have to keep changing their products within this time frame. Laser cutting technology provides that kind of flexibility to manufacturers.

Implementation of laser technology rises

Industry 4.0 is the new trend that is being implemented in all the sectors. Rakesh Agarwal, Managing Director, Laser Technologies comments, “The industry today needs smarter solutions like IoT and robotics. Nowadays, we want everything on our fingertips, and automation, robotics, IoT and Industry 4.0 are aiding that. These technologies help us manage business by sitting at one place and take our business globally.”

Fibre laser technology is going to the next level now. After the invention of fibre laser technology around 8-10 years ago and it having stabilised in the last couple of years, it is now the major driver of the sheet metal fabrication industry. So whether manufacturers are able to afford a high-end machine or not, fibre laser technology is nonetheless being increasingly applied in sheet metal fabrication. Niraj Seth, President, Amada (India) Pvt. Ltd. says, “Maintaining our technological superiority, ENSIS 9KW is the first of its kind to have beam control as well as beam collimation. So, even with a 3 kW capacity, you can cut 25-millimetre mild steel, which normally would require a capacity of 6-8 kW to cut. With ENSIS 9KW, piercing is extremely fast. On a 25mm mild steel, it takes 1 second to pierce as against at 20-22 seconds on conventional fibre cutting machines.”

For Industry 4.0 to be successfully implemented, a lot of R&D is required. Anil Kumar, Director, Angel India Cad Cam Pvt. Ltd. states, “We are representing some products from Bystronic DNE. Their target is to always do R&D and spend a huge amount on R&D.”

Fibre laser cutting is a relatively new technology, and since 2010, DURMA is involved in the manufacturing of fibre laser cutting machines. Nilesh Chanchad, Director, Chanchad Machine Tools Company explains, “Fibre laser cutting is helping the market and the companies improve their cutting quality, production, and cut for cost calculations which were very high earlier. DURMA is very popular for providing automation, handling systems and laser cutting machines together. We provide special handling systems; load/unload systems, storage systems and so on. So, we have a completely integrated range of solutions along with laser bending machines and robotics. We are now embracing the demands and needs of the new generation by joining hands with technology to make our processes faster. DURMA follows Industry 4.0 in our manufacturing and the same has a good future in India for manufacturing plants.”

With regards to the new technologies in laser cutting, Kumar mentions, “We recently launched a tube-cutting machine, which the market does not have yet. It has no comparison with other products as it is unique. The industry needs both 2D cutting and tube cutting, but we are finding that people are more moving more towards tube cutting, so we are catering to this demand accordingly by delivering the best-suited products to our customers.”

There are also new launches by Laser Technologies, on which Agarwal elaborates, “We have launched the 40206 kW machine with the HSEx controller which has the latest updates and features, and this is the fourth-generation machine. We also launched ALE200, a die-mould repair laser welding machine specifically for the Indian market. This machine has a lot of growth potential and demand from the market, so we will mainly focus on it. We will also focus on increasing the productivity and efficiency of fibre laser cutting machines this year in India.” These are just few of the launches that the industry is looking forward to.

However, adoption of any new technology takes time, as consumers need to have the right knowledge and be comfortable about using these new technologies. Kumar aptly explains, “Though there is a lot of awareness among consumers, perception still remains to be a major issue as they are more concerned about the price. They are still not open to the new advancements and technologies out there; they don’t want change. But it is just a matter of time before they begin to understand the advantages of the new technologies and start using them. Once they understand that their requirement cannot be fulfilled by the poor quality products, they will choose the better, advanced technologies that are coming up.“

Future market trends

Regarding the industry’s growth, Seth tells us, “My growth projections depend on the industry, as last year saw low growth for many manufacturers. However, Amada has been growing at 15-20 percent year on year. So it has been a good time for us and we hope to move forward with the same momentum. In the coming months, we are going to launch a new technology for laser cutting, which is called VENTIS. That’s another step ahead of what fibre technology is now. We have also launched an IoT-enabled process software that will help you to connect your ERP to the machines, so that the entire process on the shop floor is controlled by software. These are the two new technologies coming up.”

To conclude, Kumar says, “Laser technology will be the game changer in future. Since the last 3–4 years, people have been using press brakes and other such products and instruments. Today, people prefer automated devices, products and technologies. Moreover, fibre laser has transformed the overall future outlook, and it will evolve more in the near future. Looking at the pace at which the industry is becoming more tech-savvy, I feel that the conventional technologies will be taken over by laser technologies and other emerging, trending innovations.”

After the invention of fibre laser technology around 8-10 years ago and it having stabilised in the last couple of years, it is now the major driver of the sheet metal fabrication industry.

Niraj Seth, President, Amada (India) Pvt. Ltd.

We are now embracing the demands and needs of the new generation by joining hands with technology to make our processes faster.

Nilesh Chanchad, Director, Chanchad Machine Tools Company

Nowadays, we want everything on our fingertips, and automation, robotics, IoT and Industry 4.0 are aiding that.

Rakesh Agarwal, Managing Director, Laser Technologies

The steel is reusable; you melt it and then make it again. So the steel is a big, big game changer for the whole industries.

Anil Kumar, Director, Angel India Cad Cam Pvt. Ltd.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi