Factory automation: The new face of industrial growth

April 1, 2020 1:49 pm

Industrial experts come together to explain the opportunities and challenges in factory automation and how the industry can witness a new wave of growth through this important tool.

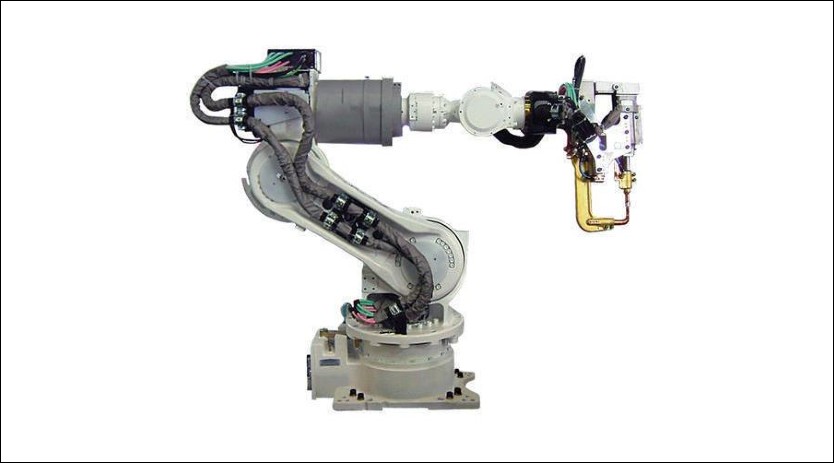

Factory automation is on the threshold of a new revolution, moving through rapid technology changes, adoption of new systems and networking architectures and looking toward interoperability of devices and systems. Factory automation with robotics helps in control of operation at different levels like pick and place applications, handling jobs with different machines, automating processes or assembly in achieving production efficiency and performance.

Drives and controls in factory automation and robotics

Drives and controls are an important constituent in the whole automation-led ecosystem at a shop floor as they play a vital role in enhancing the efficiency of the equipment such as saving energy, enhancing precision and positioning, increasing speed and bringing in smarter torque controls which add on to the overall objectives in terms of cost and productivity. Sameer Gandhi, MD, OMRON Automation, India gave an example, saying, “A Variable Frequency Drive deployed in an automation solution helps to save energy by consuming only the power that’s needed. It also brings in better motor control, simplified user interface and the ability to perform more complex applications. Another example is of servos. A servo motor could be very helpful in positioning a motor shaft at a specific position using control signals.”

V.G. Sakthikumar, Managing Director, Schwing Stetter India Private Limited, Member of governing council, ICEMA, Chairman of Mechanisation committee, Builders Association of India states, “These days, it comes with the latest cloud-based data analytical solution/tool. But still it is not made inbuilt and can be opted as an optional kit which helps us to take our factory towards Industry 4.0. We use a vast range of automation and processing technologies that helps bring higher productivity and quality to the factory floor.”

The holy trinity of motors, drives and control systems make up the core part of motion control, which in simple words defines the motion profile of a machine. Elan Anbanandam, Product Manager – Automation, ANCA Motion explains, “The movements in the machine are powered by motors, which are controlled by the drives based on the feedback from the control system.” These key components contribute to the overarching benefits of automation, such as improved quality and efficiency with reduced downtime and safety risks.

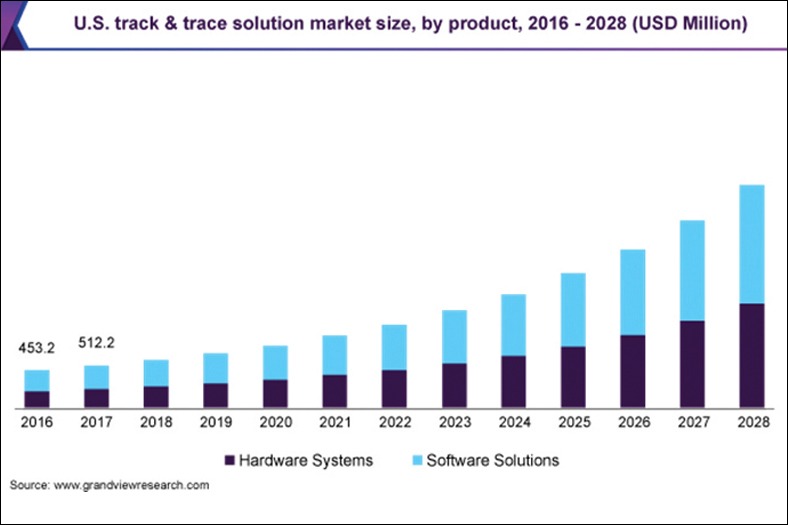

Rajesh Nath, Managing Director, German Engineering Federation (VDMA) adds, “I think “SMART” drive and control systems would significantly contribute to factory automaton. Valued at $157 billion in 2018, the global industrial automation market is expected to reach $296 by 2026 as it immensely helps in growth of productivity, enhances quality, and minimises error to a great extent.”

Today, with technology advancements, we are moving towards human-robot collaboration and robots are becoming part of machine controls. Ninad Deshpande, Head – Marketing & Corporate Communication, B&R Industrial Automation explains, “At B&R, we have already successful implemented such human-robot collaborated application on the factory floor. In addition, robots primarily were separate units in a factory usually with a separate cabinet and control unit. With B&R’s machine-centric robotics, we integrate robots in the same controller for machine control. This enables cost reduction, better space utilisation and higher speeds.”

Hurdles in increasing growth rate of factory automation

Factory automation can be divided into three parts, i.e., robotics, drives and controls, and networking. A basic challenge that the industry faces is silos of knowledge. For example, measures are required to be taken for upgrading legacy networking systems to comply with the upgradation for robotics, drives and controls. Deshpande explained further, “Growth is always a relative term. Over the years, factory automation has seen consistent growth. However, a conservative approach by factories looking at the global market slowdown might be one factor for reduced growth. Even the Budget 2020 seems promising for various MSMEs and SMEs in India.”

Some of the market restraints come from the high costs involved in replacing existing set-ups, lack of a skilled and trained workforce, and the resistance to new technology. Gandhi added, “The growth did not meet the expected rate mainly owing to the economic slowdown. The sector has always been struggling with the level of acceptance amongst end users to invest in something that is adding to the cost.” The slowdown added to the woes because of which immediate cost of purchase became one of the major concerns for many customers. Moreover, an automation system needs the right set of skills, from the point of conception to deployment to maintenance which becomes very challenging sometimes for the makers to manage.

Innovations in drives and controls, factory automation and robotics

All innovations and product upgrades in factory automation and robotics have the same vision of creating a customised, intelligent, autonomous manufacturing environment, which is an important perquisite to attain the real value out of a smart manufacturing set-up.

Nath tells us, “The convergence of advanced information, communication and networking technologies is the key driver of growth in industrial automation. This symbiosis of technologies has enabled integration and collaboration of people and machines across the factory floor and the supply chain.”

Vineet Jain, Head – Telecontrol Automation, WAGO India said, “Once integrated, control platform will enable companies to enhance efficiency and achieve plant-wide process optimisation, resulting in enhanced user experience. The prerequisites are greater programming flexibility, scalability, more memory, smaller form factor, high-speed (gigabit) Ethernet and embedded wireless functionalities, which facilitates communication between the shop floor and other business processes.”

Sakthikumar elaborated, “Industrial Internet of Things (IIoT)-enabled solutions, IoT, predictive analytics, cybersecurity, edge computing, artificial intelligence and machine learning, virtual reality/ augmented reality, autonomous equipment, connected jobsite and open process automation (OPA) front are being explored for the betterment of the CE industry’s growth.”

The major objectives of smart manufacturing are flow optimisation and customisation, asset tracking, predictive maintenance, and real-time inventory optimisation. Manufacturers are installing industrial robots to make production and distribution easy and efficient.

Final note

IT and OT infrastructures are rapidly converging. Industrial and critical infrastructure organisations are adopting IoT devices at an unprecedented rate. Blind spots across this converged IT/OT infrastructure can lead to unbearable risk. Until recently, Industrial Automation and Control Systems (IACS) were largely isolated from corporate systems by means of proprietary protocols, which facilitated their protection against cyber-attacks under the principle of security through obscurity. In recent years, there have been many evidences of cyberattacks to IACS that exploit their vulnerabilities. Prioritisation of the security objectives for IT and automation technology, the availability of the production facility has the highest priority, followed by the integrity of the facility. Measures for implementation of cyber security standards such as IEC62443, ISO27001/2 are an affirmative step towards securing the business’ critical information.

Sameer Gandhi, MD, OMRON Automation, India

A Variable Frequency Drive deployed in an automation solution helps to save energy by consuming only the power that’s needed. It also brings in better motor control, simplified user interface and the ability to perform more complex applications.

Elan Anbanandam, Product Manager – Automation, ANCA Motion

The movements in the machine are powered by motors, which are controlled by the drives based on the feedback from the control system.

Rajesh Nath, Managing Director, German Engineering Federation (VDMA)

The convergence of advanced information, communication and networking technologies is the key driver of growth in industrial automation.

Ninad Deshpande, Head – Marketing & Corporate Communication, B&R Industrial Automation

With B&R’s machine-centric robotics, we integrate robots in the same controller for machine control.

Vineet Jain, Head – Telecontrol Automation, WAGO India

Once integrated, control platform will enable companies to enhance efficiency and achieve plant-wide process optimisation, resulting in enhanced user experience.

V.G. Sakthikumar, Managing Director, Schwing Stetter India Private Limited, Member of governing council, ICEMA, Chairman of Mechanisation committee, Builders Association of India

We use a vast range of automation and processing technologies that helps bring higher productivity and quality to the factory floor.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi