Automotive Revolution

July 2, 2020 11:19 am

The automotive industry isn’t novice to automation. However, today the rise of 3D Printing powered by advanced Robotics and Information Technology is revolutionising automotive manufacturing.

Contribution of manufacturing and automobile industry to the GDP of any country is significant. Factors such as policies, cost, quality, infrastructure, and innovation play a significant role in a region’s growth in manufacturing. Innovations using new-age technologies like robotics and 3D Printing, and Information Technology (IT) help fasten the growth.

ITs were well adapted in the design of a product in the last two decades. This is being extended to the core manufacturing operations through manufacturing execution systems and supply chain. From a digital planning to a physical output to a digital control, manufacturing and design processes need to work in a closed loop system to create a strong control of the processes, observed Sharadhi Babu, CEO, AXISCADES.

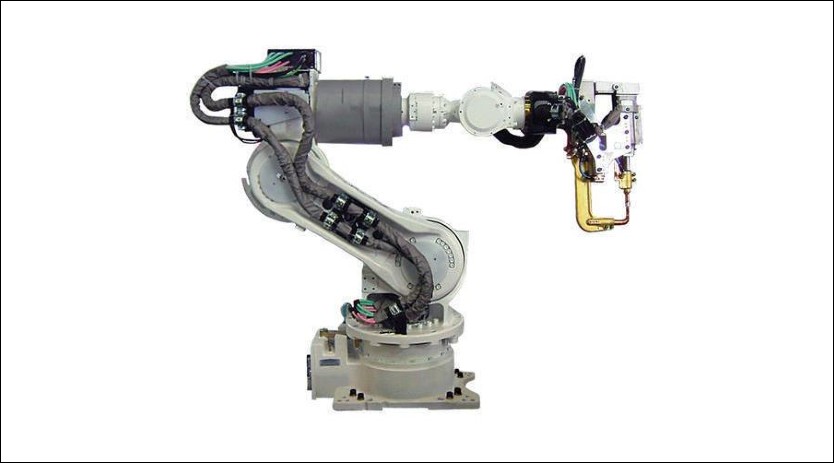

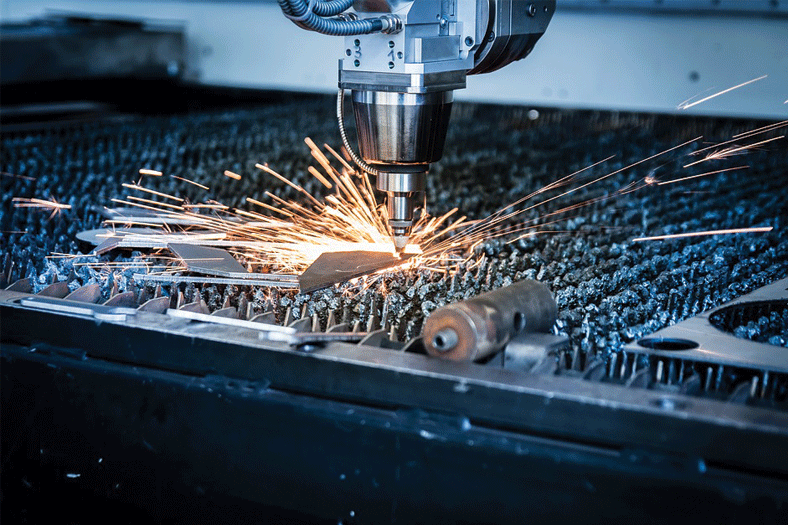

Robotics and 3D Printing have played a key role in precision manufacturing and design. Robots are used widely in key assembly processes like welding, etc which determines the strength and safety of a product structure. 3D Printing or Additive Manufacturing are used much early in a design cycle to understand the performance of the product along with the design. “Complex geometries are achieved in metal and non-metal additive manufacturing techniques which is evolving and being integrated in the overall manufacturing processes,” Sharadhi said.

3D Printing technology is now an essential part of progressive business solutions and processes in many factories. There are many advantages to 3D Printing but precision to manufacturing is one of the main reasons why high-tech industries are harnessing this technology to perfect their craft, William Lee, Channel Sales Director, Ultimaker Asia Pacific opines.

Explaining the advantages further, he said, “3D Printing is an additive process that leaves no excess materials. This process of manufacturing significantly reduces material wastage and processing time. 3D Printing allows printing of geometrically complex shapes as long as the proper support material is given. This contrasts with traditional methods such as moulds and cutting technologies which will cost more to print the same object.”

In addition, 3D Printing allows step-by-step assembly of the part to ensure enhanced designs and better printouts. A printed prototype allows close examinations on whether modifications are needed before embarking on mass-printing. This helps companies save costs before committing to bulk print orders, said William.

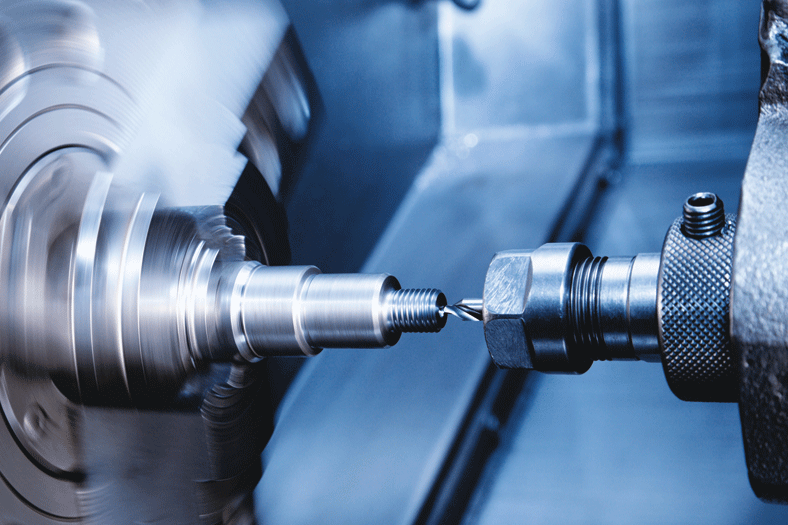

With the implementation of 3D Printing, manufacturing industries and the automotive sector are finding Additive Manufacturing as an essential part of value creation in product manufacturing. According to Ganesh Babu, National Manager Additive Manufacturing, DesignTech Systems Pvt. Ltd., “3D Printing technologies are enablers of digitalisation in the manufacturing process and supply chain. Customer needs are captured and customised solutions are implemented in today’s decentralised business modules. Industrial grade 3D Printers are capable to manufacture parts with great precision and repetitive quality for prototyping, manufacturing tooling and end use parts.”

Design Iterations at an early stage in product development brings about being faster to market, with first time right solutions. “3D Printing as a technology allows the manufacturing of physical goods directly from digital data (3D CAD) with the use of Internet as a communication tool, shortening the manufacturing cycle time,” Ganesh adds.

Omron, with its array of end-to-end solutions in the automation arena, has been serving the machine builders as well as the automotive companies to scale up the value chain so that their products match the global standards in terms of productivity, efficiency, speed and safety.

The automotive manufacturing segment is one of the most promising segments showing impressive results in the adoption of robotics and IT based solutions, informs Sameer Gandhi, Managing Director, OMRON Automation India. He adds, “OMRON’s robotic solutions – Cobots, SCARA robots, Articulated Robots and Parallel robots as well as Vision system – synchronise movement, facilitate part movement, and enable assembly of very intricate designs with speed and precision delivering numerous benefits such as increase uptime and through put, high levels of safety and utilisation of less space and energy.”

OMRON Mobile Robots are adding a lot of value to many ancillary industries in the automotive domain like tyre makers by creating collaboration between human beings and machines to increase productivity in varied operations.

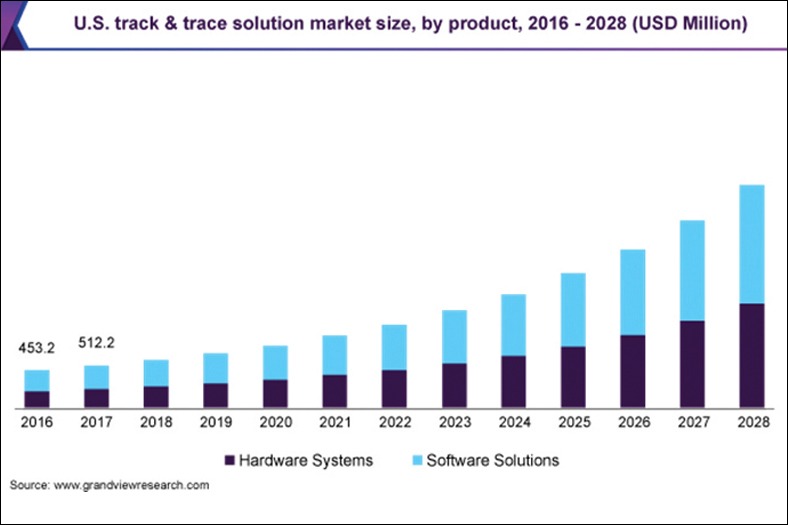

“We also have been empowering the automotive makers to ensure zero-defects manufacturing and manage recalls by rendering intelligence to the quality checks via IoT enabled applications. We are the leading player for automotive traceability and we have one of the largest product and solution portfolios in the segment ranging from Laser Markers, Barcode Readers and Verifiers, RFID readers as well as Machine Controllers that can read/write from the MES/ERP layer to support the implementation of traceability,” claims Gandhi.

OMRON’s Total Traceability solution provides manufacturers the ability to trace and verify the history, location, or application of an item by means of documented recorded identification. Considering one defective product can bring humongous loss and setbacks to the credibility of a brand, the solution holds a lot of importance to ensure zero-defects manufacturing system. This attains more significance for the automotive industry where assembling of multiple complex components needs constant checking at every step and product-recalls are witnessed quite often.

Further, Cloud computing and analytics are empowering the makers to utilise the data to create immense value at the shop floors. A lot of data is gathered from the shop floor using IIoT via smart sensors, vision, RFID, etc. The new advanced generation of PLCs can move this data very rapidly into the MES/ERP/Cloud layer and thus give the shop floor managers a pool of valuable information to be worked upon which helps them to initiate real time measures such as predictive maintenance by identifying potential issues as well as implementing productivity solutions.

Effects of 3D Printing, IT and Robotics on HR

Robotics and IT based applications are creation of man itself and they are programmed to do as how we want them to perform. In fact, robots and Artificial Intelligence are proof of concepts of the harmony and interface between humans and machines. Operating these robots requires a skilled work-force which means an opportunity of job creation, however with better and more advanced skill sets, said Gandhi. “This impacts human resources by requiring to upskill the workforce.”

He adds, “The purpose is that workers do not lose their creative and out-of-the-box talent by executing time-consuming, repetitive or potentially unsafe jobs that are best performed by a machine or a robot.” OMRON takes the view that by getting machines to do repetitive tasks, man is freed to do more fulfilling work. ‘To the machine, the work of the machine; to man, the thrill of further creation’- one of the visionary statements of Omron’s founder Kazuma Tateisi, made almost five decades back (1970), make a lot of sense in today’s scenario, especially to the ‘new normal’ created by COVID-19.

Another important aspect to consider is that robots and IT help improve productivity besides quality. As per Gandhi: “A more productive and quality-oriented manufacturing enterprise is likely to prosper more, especially considering that the market and competition is not limited to India alone. Hence, such a manufacturing is also likely to invest more and perhaps set up more lines or units thus generating employment. So, this is the second impact of robotics and IT on human resources.”

And now, in the new normal where manufacturers are grappling with implementing safety guidelines (social distancing, etc.) at the shop floor and lesser availability of skilled manpower owing to labour migration, automation is the need of the hour to answer to these needs, to remain competitive in the industry and to produce products which are expected to be consistent and high in quality, increased output, and decreased costs.

The adoption of technologies like 3D Printing, Robotics, and IT along with many other new-age technologies enhance the ability of a manufacturing enterprise towards an adaptive manufacturing. With the current rapid change of business dynamics due to environmental concerns or customer needs, enterprises are reinventing themselves to be successful. Even products keep changing dynamically and an enterprise can be made agile by investing in Industry 4.0 methodology. In Sharadhi Babu’s opinion, by introducing these technologies, there will be a big surge of employment for those that are well versed in IT and manufacturing operations technology as these have to interact on continuous basis. He said, “Like how skilled IT boomed due to automations and reducing the complexities, new-age technology would throw challenges of new skill gap as well as reskilled manpower to handle a closed loop manufacturing system.”

Robotics is the only way to achieve accurate and precision manufacturing methods, Sharadhi feels. . However, he adds, “Manpower needs to be augmented to handle the programming aspects, achieve complex manufacturing in lesser time, have the ability to carry out tasks in spite of hazardous environments and finally the robotics intent to achieve higher productive results.”

Adoption of 3D Printing by automotive industries will have a positive impact to the existing workforce as it is a beneficial tool in the design or manufacturing lines, believes Ganesh Babu. “3D Printing is a complimentary technology that supports the manufacturing or production processes and should have positive impacts and not a threat to manpower. Manpower gets to use more advanced solutions and techniques for better productivity and to a smarter manufacturing solution.”

So, it is proven that there are immense opportunities for 3D Printing to be successfully harnessed in multiple use cases in key industries. Many manufacturers have already embarked on their digital journey, utilising 3D Printing as an essential part of their automated workflow, boost their supply chains, or simply to help humans work smarter and more efficiently.

“3D Printing technology is poised to transform the way companies do business. While it has helped to automate many processes, which inevitably displaces some roles along the way, it has also opened up opportunities in engineering, research & development, design and operations. As technology evolves, workers must upskill/reskill along the way so they can stay relevant and continue to contribute to the workforce of tomorrow,” concludes William.

A more productive and quality-oriented manufacturing enterprise is likely to prosper more, especially considering that the market and competition is not limited to India alone.

Sameer Gandhi, Managing Director, OMRON Automation India

Robotics is the only way to achieve accurate and precision manufacturing methods.

Sharadhi Babu, CEO,AXISCADES

As technology evolves, workers must upskill/reskill along the way so they can stay relevant and continue to contribute to the workforce of tomorrow.

William Lee, Channel Sales Director, Ultimaker Asia Pacific

Adoption of 3D Printing by automotive industries will have a positive impact to the existing workforce as it is a beneficial tool in the design or manufacturing lines.

Ganesh Babu, National Manager Additive Manufacturing, DesignTech Systems Pvt. Ltd.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi