A Step forward to Pharma Automation with TURCK

December 7, 2020 2:29 pm

Looking at today’s COVID-19 situation, the importance of the pharma industry is at the peak. Rather it is the time where social media is also bringing awareness about who is producing what.

In general, when people talk about the pharma industry, discussion majorly happens about either API units or formulation plants. However, we miss the major contribution of pharmaceutical machine manufacturers. All the pharma OEMs play a very vital role in the industry as they become the heart of all the drug manufacturing plants.

TURCK has been quite actively contributing to an increase in the efficiency of the Pharma machines using various concepts and solutions. Using Fieldbus technology, Turck has been pushing the modular machine concept to become reality. This has been helping so many pharma machine manufacturers to optimize their machines such as fluid bed dryers, tablet press or coating machines, etc. To withstand CIP and SIP operations, Turck’s IP69K modules play a prime role in keeping the IO connections safe.

After the implementation of the modular machine’s concept using the TBEN series, we’ve successfully helped many OEMs to achieve smaller machine footprints with lesser I&C times. All the conventional way of installation & IO termination gets a new face of distributed IO systems.

Using Multi-protocol technology, Turck has made pharma OEMs work easier with more flexibility. It’s quite high time that Pharma OEMs need to come into the new flow of efficiency improvement. Since pharma companies are nowadays loaded with either R&D or production work, it becomes very important automation companies should come forward and help them maintain their control as well as monitoring precise and intact.

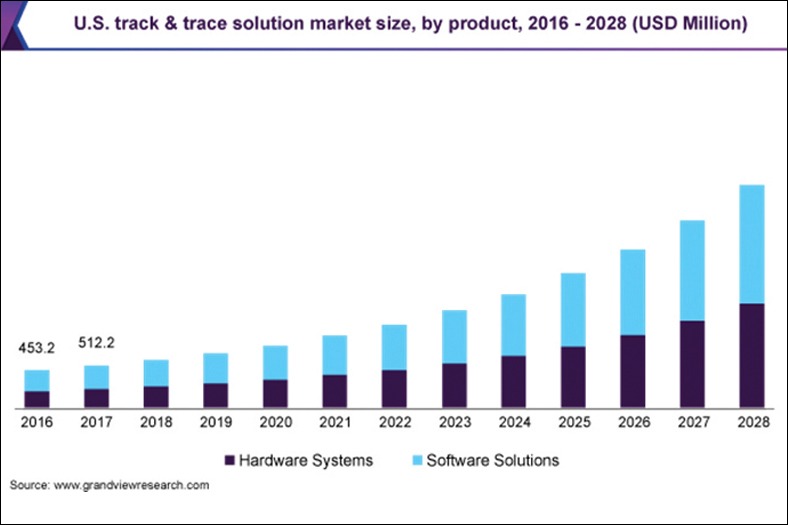

With ample experience in RFID technology projects, Turck has been helping pharma OEMs as well as end-users to track or identify parts and process. With HF technology, the company has been helping many OEMs to get the triggers from RFID to identify the right container, hose pipes, blenders etc.

Also, using Turck Vilant Solutions, they have been providing many end-users solutions to make their production monitoring, report generations, document tracking easier than ever. This is not only helping them improve their production practices but also building a strong backbone for audits.

All in all, it is the correct time to bring positive change using automation at OEMs as well as end-users to cope up with future demands of good health!

For more details, contact at: India@turck.com or

visit: www.turck.co.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi