Henkel to open ‘Smart Factory’ near Pune

March 13, 2018 3:10 pm

Henkel Adhesives Technologies India Pvt Ltd is one of the world’s leading manufacturers of adhesives, sealants and functional coatings. Responding to the Indian market’s growth potential, Henkel is all set to open a new plant for adhesives, sealants and surface treatment products at Kurkumbh near Pune. Excerpts from an interview with Shilip Kumar, President – Henkel in India:

When it comes to forming technology, where does Henkel stand?

We are a solution provider in the metal forming industry. Henkel has solutions for the complete value chain including casting, forging, machining and grinding as well as the cleaning operation.

We introduced Bonderite duaLCys last year in India. This technology offers synergies between a lubricant and a cleaner. The new process requires less water, minimises waste and saves energy by allowing the washer bath to operate at a lower temperature. We are pleased with the acceptance of this technology in the Indian market since introduction.

How do you look at the market for speciality chemicals like yours?

Overall the market has been very positive, and we are growing as per our targets. We expect to continue our journey of robust growth in India.

What makes you different from your competitors?

As an organisation, we are committed to deliver to our customers innovative solutions that enhance the efficiency of their operations or products. We work with our customers closely right from the designing stage. This helps the customer and us to understand the problem, and design the right solution within the budgeted cost.

We continue to replace methods such as welding, fastening, thread seal tape and other conventional methods of bonding and sealing with advanced technology liquid adhesives and sealants.

Further, we offer premier surface technology and process solutions under the Bonderite brand to most of the leading OEMs present in India. We also supply to the tier 1 and tier 2 component suppliers who in turn supply to these OEMs. The expanse of the industries that we supply to is vast.

Henkel is a global major in the field of speciality chemicals headquartered in Düsseldorf, Germany. How significant is your presence in India?

The adhesive technologies business of Henkel in India is primarily in the business-to-business realm. It makes a difference in virtually all areas of manufacturing activity and our everyday lives: from smartphones to food packaging, from cars to airplanes, from construction to industrial plants.

India holds a strategic position for Henkel as a part of the company’s long-term growth strategy both as a domestic market and as a base to serve other international markets. Our biggest focus areas are strengthening Henkel India’s manufacturing and product development footprints in the country.

Innovation has been the key driver of our growth. Our innovation center at Pune was set up with the aim to develop products finding applications across multiple industries. At present, we have a core team of 50 engineers and scientists at the innovation center. The innovation center also houses an Acoustic lab and an MRO (Maintenance, Repair and Overhaul) Center of Excellence. The MRO center focuses on increasing reliability and efficiency of its customers. The acoustic lab facilitates vehicle, appliance and component level testing for different applications as per international standards. It also helps in high level product validation testing.

Could you let us know about your expansion plans in India?

In 2016, we opened an Acoustic lab at our Pune innovation centre for automotive and general industry. The lab facilitates vehicle and component level testing for different applications as per international standards.

In 2017, we set up a MRO at the same facility which is fully equipped to develop and offer Loctite solutions to rebuild, repair and protect industrial equipment.

On the manufacturing front, we are coming up with a greenfield plant near Pune to enhance our production capacity. The first phase of the plant is being set up with an investment of 30 million Euros. It will be commissioned in the first half of current year.

What are the products will be manufactured at the upcoming plant?

This multi-technology plant will produce adhesives, sealants and surface treatment products. In Phase One, we will manufacture metal pre-treatment chemicals as well as laminating adhesives for flexible packaging.

Tell us more about the ‘smart’ components of the new facility.

The new facility near Pune will be future-ready and Industry 4.0 enabled manufacturing set-up. It will secure capacities to meet the fast-growing demand, especially in emerging markets.

The facility will leverage scale and advanced infrastructure to ensure world-class quality and safety standards. The smart plant would utilise globally available best practices and technologies in manufacturing of adhesives, sealants and surface treatment products.

The site will have dedicated facilities for manufacturing solvent-based, solvent-free and water-based adhesives to avoid cross contamination risk and time-consuming cleaning cycles. It will be equipped with closed material handling systems which protect the finished goods from external impurities. The site will be Industry 4.0 (MES – Manufacturing Execution System) enabled ensuring fully automated, data-controlled production environment, providing traceability and process correction flexibility.

we are coming up with a greenfield plant near Pune to enhance our production capacity. The first phase of the plant is being set up with an investment of 30 million Euros.

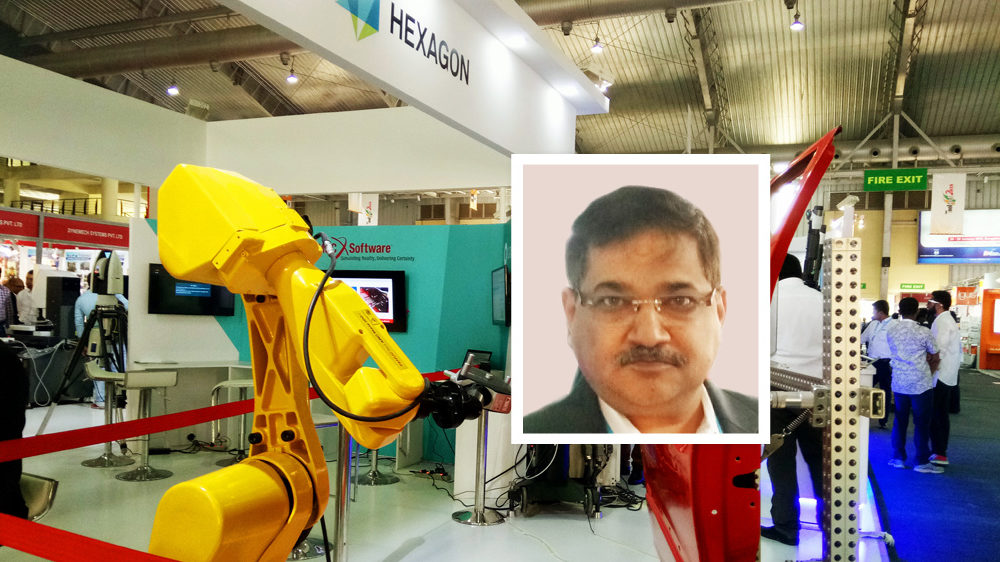

Shilip Kumar,

President, Henkel in India

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.