The pros & cons of reconditioned parts

December 7, 2020 2:35 pm

This article explains the benefits of reconditioned, refurbished or remanufactured parts.

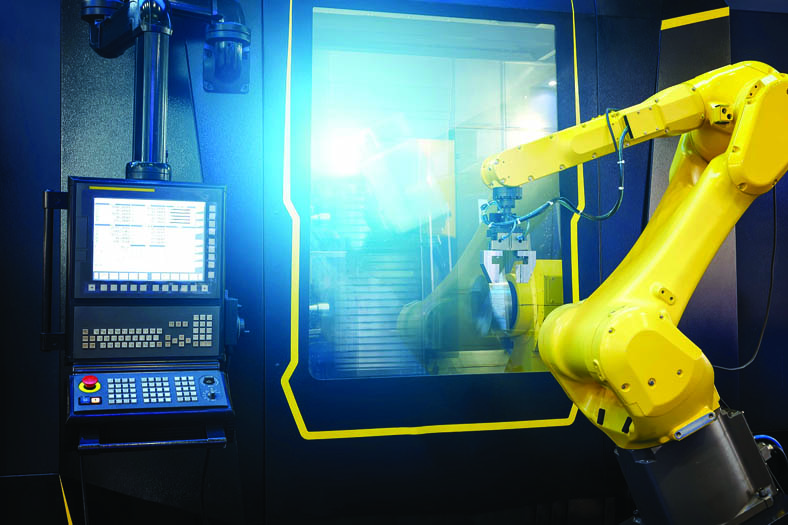

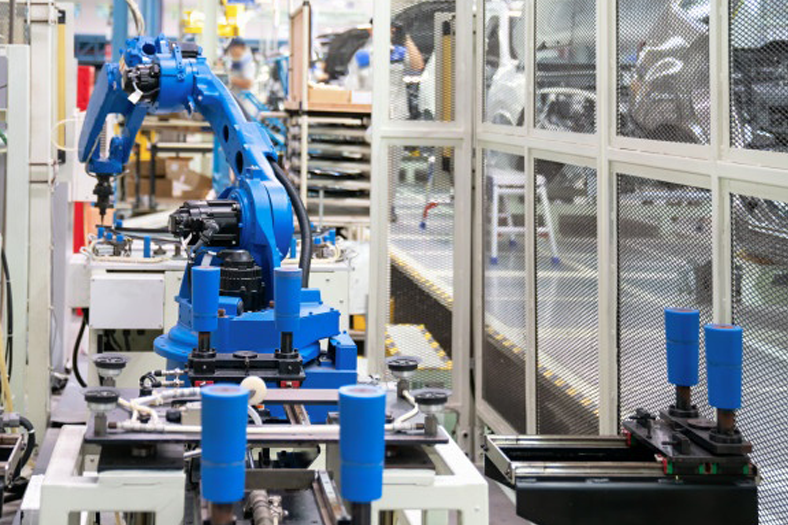

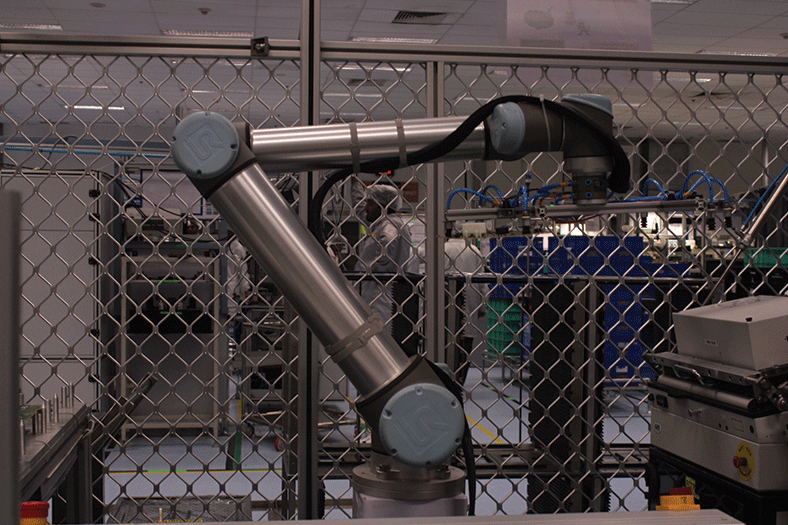

Consider the following scenario. A piece of factory equipment at a car manufacturing factory malfunctions, bringing production to a halt. The plant engineer or maintenance manager must source a replacement part but finds purchasing a new part to be prohibitively expensive. Perhaps a cheaper option is to dabble in the world of used parts?

Looking online, they find tantalizingly low price tags to tempt them into the world of virtual auctions. A used version of the part is available and swift delivery is promised. Yet when the would-be purchaser enquires about the condition or the part, how long it has been used for or whether it matches the required specifications, adequate answers are not forthcoming. With only a three-month warranty and with the condition of the part unknown, the plant manager risks the prospect of the replacement part failing within months or even weeks of purchase.

Reconditioned, refurbished or remanufactured parts offer a solution to this dilemma. In quality and reliability, they are often much closer to brand new parts than conventional wisdom would have us believe. Yet on price, although more expensive than used or repaired parts, they are substantially cheaper than buying new parts.

Know what you are getting

Let’s start with some definitional ground clearing. Reconditioned, refurbished, or remanufactured? What is the difference? The short answer is that there is no difference. Without an industry-wide agreement on what these refer to, the terms are used interchangeably. Be sure to check with your supplier what they mean when they say reconditioned or refurbished.

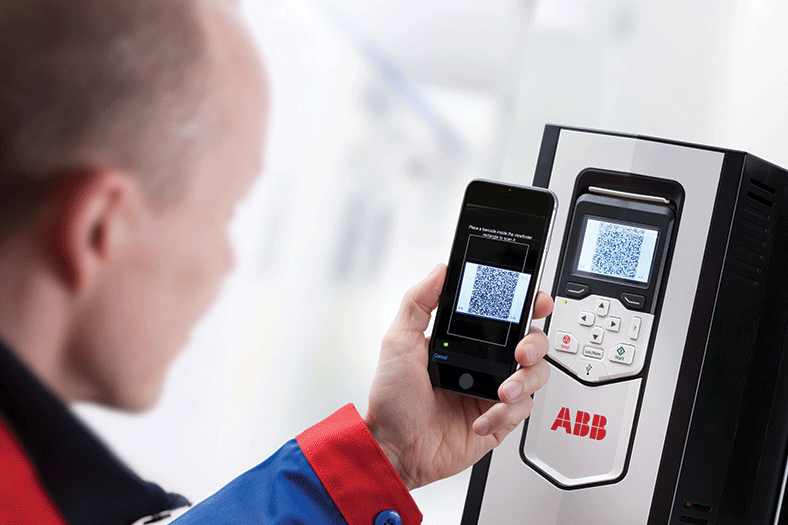

In general though, refurbished or reconditioned parts are used, original components that have been cleaned, thoroughly inspected and had any worn or damaged elements replaced. This process returns them to the original factory specifications.

In some instances, the part may be practically brand new. For example, a new part that has suffered cosmetic damage, comes in an unopened box or is missing its instructions cannot be sold as new. Instead, this will be sold as a refurbished or reconditioned part despite the fact that is has never been used.

In contrast to the above, a used part will not have gone through any of the cleaning, servicing or quality control that a refurbished part has to undergo. If the part has been repaired, then only the defective component will have been checked and the part will merely have been restored to a functional state with no guarantees of lasting performance.

Costs versus risks

Other factors being equal, we can expect a brand new part to perform more reliably than a reconditioned or refurbished part. In practice though, the difference will often be negligible or non-existent. Reconditioned parts are tested to ensure their performance can match that of a new part.

Furthermore, reconditioned parts typically come with a warranty to further reduce the risk. Although different suppliers have different policies, it will generally be the case that refurbished parts have much shorter warranties or perhaps no warranty at all.

With reconditioned or refurbished parts, you may find yourself paying substantially less for a part that is almost identical in condition and quality to an original, new part. In fact, in some instances the reconditioned part might be more reliable than a new part. If a reconditioned part has proven itself in its ‘first life’, the chances are there won’t be any teething problems in its ‘second life’.

With used parts, you will be paying less money up front but this comes with considerable risk. You do not know how long the part has previously been used for, how intensively it has been used or whether it has been maintained properly. It is a leap into the unknown. Considering the high costs of unplanned downtime in many industries, it is not a risk worth taking. Reconditioned parts can provide many of the benefits of new parts but at a much lower price.

Authored by:

John Young, APAC Director

EU Automation

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.