The 101 of the Injection Moulding Process

July 8, 2020 3:11 pm

There are hundreds of injection moulding terms used in the industry. Here Kishan Jain, Director at Goldmedal Electricals gives an introduction of the injection moulding process.

Injection moulding is a widely used process in manufacturing of any plastic product. It is a major part of the plastics industry and has been integral to the growing global manufacturing businesses. The process of injection moulding is fast, meant to manufacture large amounts of the same product in a short span of time. The injection moulding process has become one of the most popular modern manufacturing techniques. There are versatile applications of the injection moulding and can produce a myriad of parts for various products. The moulding processing of products is actively used in every modern manufacturing industry where plastic products are required including aviation, automobile, aerospace, electronics, medical equipment, consumer goods etc.

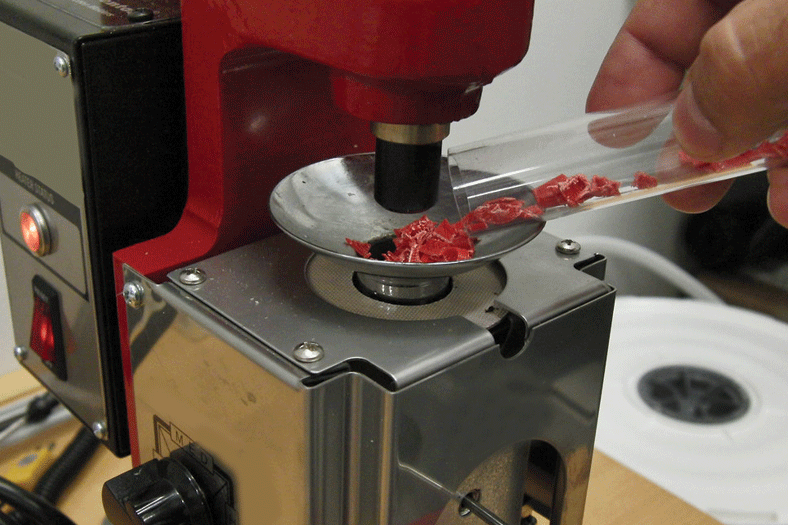

The basic manufacturing process of injection moulding is quite simple. A thermoplastic polymer or plastic is heated above its melting point in an injection moulding machine. This converts the plastic to a molten fluid, which is then injected in a mould cavity and subjected to a high pressure. Finally, it is cooled, solidified and removed from the mould. This process gives the product a solid form and predefined shape. Many of our day-to-day items around us have been manufactured using this process—from the lids of our Tupperware containers to plastic parts of our electrical appliance to our toys.

The process is carried out in a moulding machine, commonly known as an injection press. This machine has three basic parts: the injection unit, the mould and the clamping system. There is also an elaborate control system that automatically administers the moulding functions. Injection moulding machines come in various sizes and capacities from 50 tonnes of clamping force to more than 6000. There are also different kinds of injection moulding machines available in the market and are categorized based on the driving system used–hydraulic, mechanical, electric and hybrid machines. The machines are available with a choice in the size of injection unit as smaller injection units provide better accuracy for producing relatively smaller parts. Furthermore, there are other customizable parts of the machine as per the need of the manufacturer.

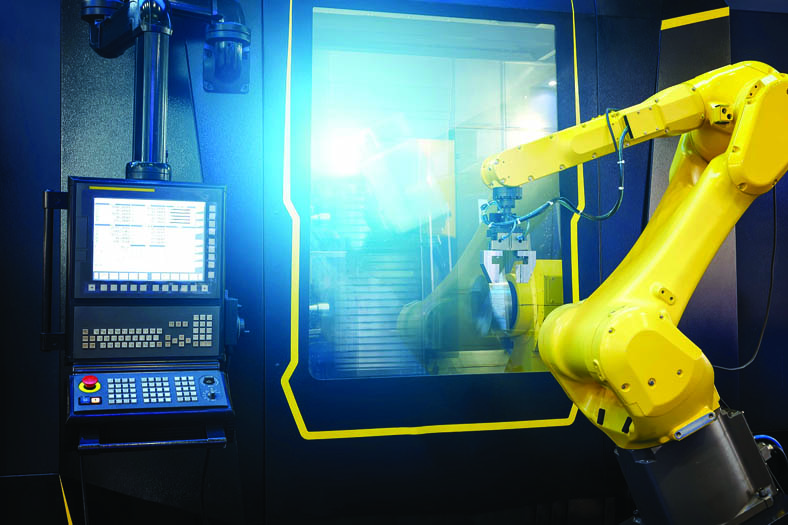

There are many unique advantages of injection moulding, which has made it an important process in the modern manufacturing industry. This process enables fast production of very complex and detail-oriented parts while maintaining highest quality and precise size. Once a well-designed and errorless mould has been created, the injection moulding process is fairly repeatable and aids bulk production. Due to its ability to make multi-cavity injection mould parts, multiple parts can be produced in one cycle that are identical and precise. Unlike the CNC machining, this process has relatively low scrap rate and does not cut away considerable portions of the material. Some of the other advantages of this process include low labour costs; flexibility to choose from a range of raw materials and colour, parts produced display enhanced strength and durability, and involves minimal post-moulding finishing procedures.

Because of the ever-evolving nature of technology, nothing is perfect. This process is no exception and is riddled with a few challenges. The major drawback of injection moulding is that the up front costs are usually extremely high due to its design, testing, tooling and machine needs. Furthermore, since the tools are usually made of steel or aluminium, making changes are extremely difficult. Some complex parts may encounter moulding defects like flow lines, burn marks, warpage, weld lines, jetting and vacuum voids. In case injection speed is not monitored, it may cause flow lines, which are off-tone strips, patterns or lines. Due to excessive heating, the part may have burn marks. Similarly, if proper cooling processes are not followed then it may cause warpage and cause the part to be twisted, uneven or bent. Due to insufficient holding pressure, it may trap small air pockets inside of the moulded part resulting in a faulty final part. Although there seem to be many challenges, with proper care and attention to process can help prevent most issues.

The advanced process of injection moulding is revolutionizing the manufacturing sector. The electrical segment has also benefitted greatly from this process asit makes the mass production of complicated shapes easier and faster. Moreover, the products manufactured havea uniform shape and are strong as well as durable. The upfront investment in a moulding machine can seem a lot but it can singlehandedly ensure that high quality, defectfree and robust products are delivered while involving minimum human intervention.

Authored by: Kishan Jain, Director Goldmedal Electricals

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.