Making “Smart Manufacturing” work is different & challenging than “Smart Manufacturing” itself

September 8, 2020 12:12 pm

In the early hours of Apr, 14, 2018 Elon Musk tweeted: “Yes, excessive automation at Tesla was a mistake.” Well, is this indication that maybe, just maybe, digitisation needs a deeper thought before it is assumed to be panacea for problems like productivity, utilisation etc.

Let’s talk about a case in India to understand this “Digitisation, IoT (Internet of Things) or IIoT (Industrial Internet of Things), Smart Factories” applications.

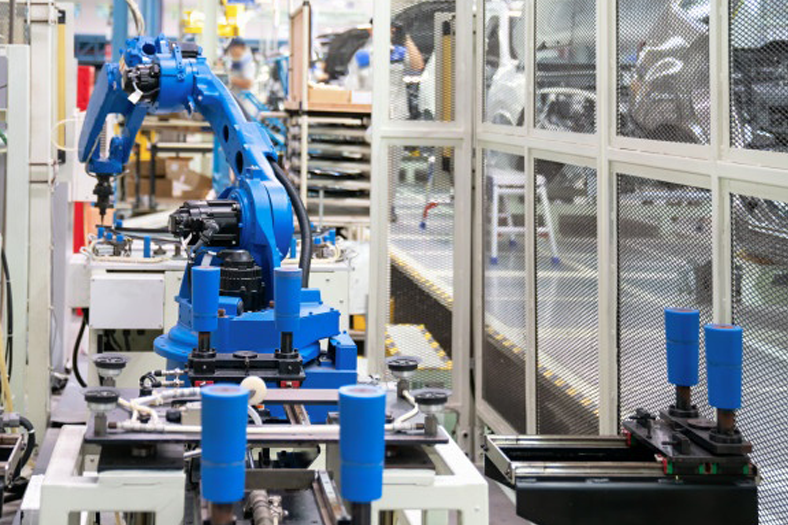

In the outskirts of Pune a Tier 1 OEM supplier (one of the biggest globally in its business) is creating an operations master plan for the year 2016-2017. “Our margins are diminishing and we need some breakthrough idea to reduce costs to retain margins,” said the Manufacturing Director. Our people as well as people costs are high and we need automation to manage that, he continued.

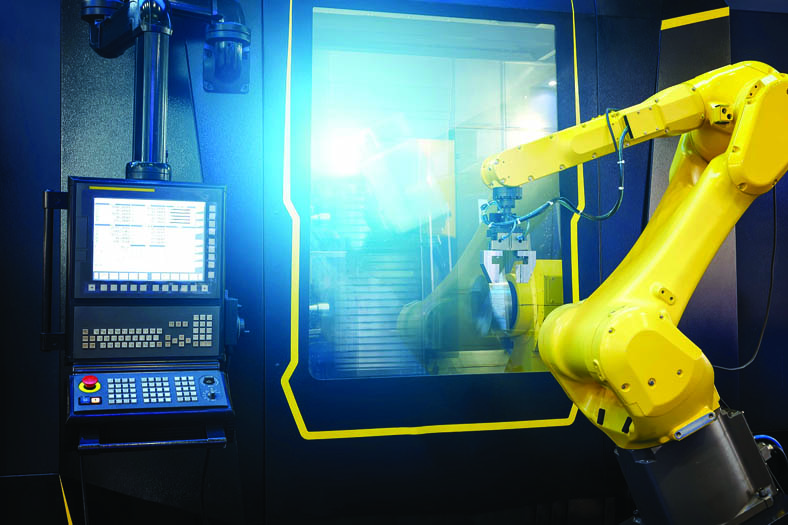

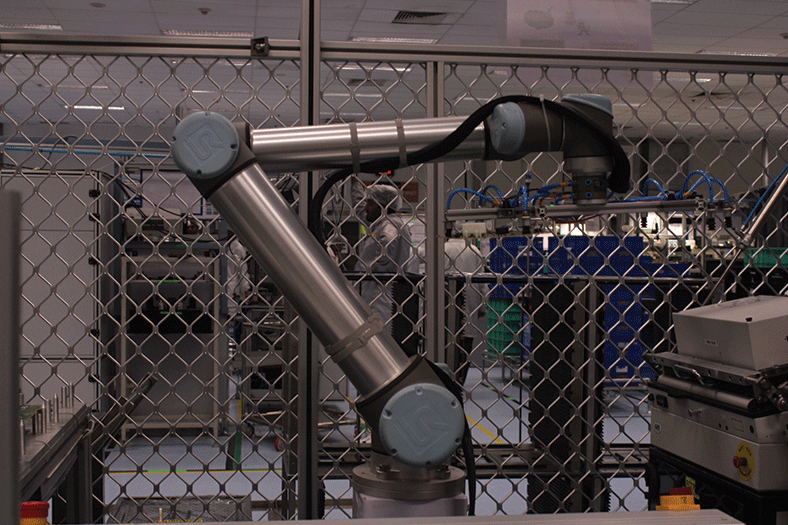

“We have already invested a lot on automation last couple of years but our costs have not really come down,” said the CFO shrugging his shoulders, manufacturing needs to do more to reduce cost. After a pause of silence one of the production managers says, “Sir, automation is not enough, we need digitisation or IoT to take our factory to the next level of operations.” Hmm, you know about IoT or IIoT? In fact after attending the session on IIoT last year we never took it up. I want to minimise human intervention all across the factory and delegate decision to machines, that’s the only way, said the Manufacturing Director. Let’s get to work and let Industry 4.0, IIoT or IoT be one of our key initiatives for the next year. I need a plan in next three weeks on how we will implement this and what benefits can we expect out of it – were the Director’s closing comments.

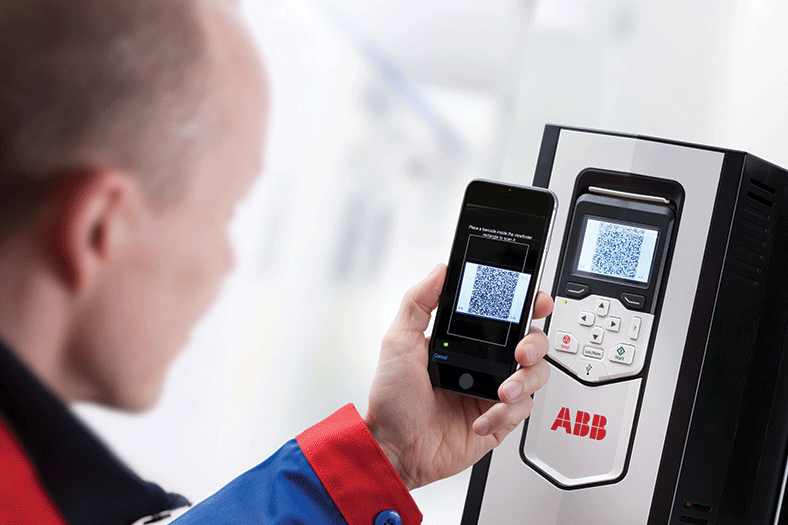

A macro plan and roadmap is submitted by the Operational Excellence team with expected deliverables like 105 machines will be IoT-enabled and 28 percent reduction in manpower can be achieved in the selected areas or machines. Hmm…that seems to be quite an impact but what about investment? , asked the Director. Well, we need some sensors, microcontrollers, wireless connectivity modules, Cloud-based app and identify some application areas, said the Operational Excellence manager. “I think we will use it for predictive maintenance application to start with.”

So, the preparation began – a “digitisation department” is set up and is asked to identify the implementation area/s, a team is established, vendors shortlisted and the journey begin. Eight months later, implementation is complete in 6 machines to predict most repetitive failures of parts like spindle, gears, tools etc , data in csv form with 14 columns and more than 100,000 rows from 30-plus sensors captured on a daily basis and a monthly review on the progress happens without fail. So what was delivered?

• POC is complete for IoT or digitisation.

• The connections of the sensors, nodes, microcontrollers and app established.

• Some predictive reports generated.

• Based on the reports actions were taken to service/repair some of the parts.

• The app enables to take some decisions remotely like allocating work, monitor time taken for work completion, utilisation of people etc.

However, some of the unanswered questions of the Director were:

• How much did my OTIF improve?

• How much was my throughput improvement?

• How much did I save?

• What’s the ROI estimate?

But the real question is after doing so much work, why achieving the “Business” and the “Customer” metric still remain elusive. Let’s try and understand the art and science behind it.

What went right? And what were the opportunities we missed?

Let’s park the investment and ROI story on the sidelines for some time and talk about the operational aspects of the case above. So, what went right?

POC successful.

Indications that IIoT or IoT can work and can be used in preventive and production scenarios.

Use of data and data analytics.

What we probably missed?

The graph here from Aberdeen Group suggests a few areas of impact; however it does miss out a key metric. The Customer? So some of what we missed are:

• The identified machines were probably not the “Biggest Flow Stoppers” ( a flow stopper is akin to a bottleneck in the whole value stream) and so, although a point improvement

was seen but line improvement metric like OTIF or Line OEE did not show up.

• Although, we could predict the failure of the part and took necessary actions, but, the MTTR (the Mean Time To Repair) metric did not improve as the “Repair Value Stream” was not taken into account.

• With the generation of huge amount data, the process obtaining, cleaning, scrubbing and analysing the data is still being done manually and needs a data scientist as an additional team member.

• As the focus moved to “automation or digitisation” the larger picture of man-machine separation was missed out, which could have been achieved by other , probably simpler, solution and most importantly with involvement of people right upto the shop floor level .

• Resource Efficiency took precedence over flow efficiency. In simple terms digitisation or IoT cannot simply be the vision rather it should enable the vision of the business and that is to serve customers in value added ways and ofcourse make money.

The “Better Approach”

“We’re not competitor obsessed, we’re customer obsessed. We start with the customer and we work backwards.” – Jeff Bezos

The missing link in this journey of IIoT or IoT, especially in the Indian context, is that most of the manufacturing companies have Industry 2.0 machines and want them to deliver Industry 4.0 standards. Secondly, “data generation and collection at the source still remains a tough ask. It’s easier with services but not as simple in manufacturing and thirdly, the maturity and skill levels, again from a manufacturing perspective, as we go down the hierarchy of an organisation are very different as compared to other industries, which more often than not becomes a difficult bridge to cross, not because of unwillingness but mostly because of the “Prison of Familiarity” syndrome.

All businesses really manage only two flows, the process or material flow and the key point here is that the information flow actually enables “customer satisfaction” which manifests itself as material/service delivery. There’s cash flow as well but it’s a function of the other two business flows. If we dig a little, it turns out that the flow of process is really a function of the flow of information and flow of information in turn is a function of decision making. So, essentially, the faster the decisions are made the faster the information flows which in turn makes the process or material flow faster which enables a business to serve its customers.

Now, looking at IoT, IIoT or digitisation, we see that what it is trying to do is to enable decision making faster and delegate-able and the ultimate factory would be sequence of machines that decides on its own how to and what to do and then does it. Which means that the decision taking ability has to be handed over to the machines but the big question is: “How much information you want the machine to process and how many decisions would you want it to take?” Having said that, if all that is done and yet we are unable to make our customers happy then it becomes a classy case of “Resource Efficiency” only, which means we could be in one of the best connected and well utilised factories minus the customers.

So, the challenge at hand is that if you already have assets, how do we align them with the “flow of customer needs” and how do we use technology to make it better by the day. Essentially then the true North becomes connecting the Source with the Receiver directly and taking out everything out of the way that acts as a “Stopper” between them.

To summarise, identifying what is it that our business needs to deliver to its customer, connecting it with the flow of the business and enabling the flow to become faster and smooth becomes our perpetual goal. Now, if we enter the IoT or IIoT universe, we would have great questions to answer. For instance, which “flows” to automate, which machines to be made intelligent, which metrics to be predicted, which data set to be collected and analysed and most importantly what not to change in addition to host of other questions. This will change and align everything from end-to-end.

So, if you are trying to run a POC for IoT, IIoT or digitisation, just tweak it and call it COPOC (Customer Oriented Proof of Concept) and see how the focus of the business just shifts from cost reduction to new growth opportunities. Finally to end, do try this “thought experiment”, focus on not benchmarking yourself with competition but in identifying “Unmet/Unexperienced” needs of your customer and use technology to enable that flow.

BMGI would like to partner with industry players to generate powerful and actionable insights, leveraging the world-class technological infrastructure and support in conducting mobile ethnography studies, as well as building internal capability at your end to do so.

Authored by:

Dr Shubhrangshu Roy, Business Head, BMGI

info@bmgindia.com www.bmgindia.com

Tele: +91-22-40020045

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi