Test and measurement automation: Need of the hour

August 13, 2018 2:02 pm

Explaining the significance of test and measurement automation for the manufacturing sector

In today’s modern development workflow process, speed is the king. The faster he/she can test, the faster his/her product can go to market. However, most Quality Assurance (QA) folks are stuck using the same old tools and processes and never get a free minute to investigate how to make their work better than usual, let alone shift to automated testing processes to help them deliver better products faster.

Innovative manufacturing – A new era

According to Varun Arora, National Sales Manager, Exor India Pvt Ltd, “Businesses that make a transition to innovative manufacturing enjoy a number of advantages. Reduced labour costs, maximised asset utilisation rates, faster product changes, reduced machine downtime, inventory and maintenance time.” He adds, “Greater flexibility in the manufacturing process increases the value of products and improves margins.”

However, international competition is increasingly intense. To maintain the competitiveness of companies and increase their productivity on national and international markets, they have no choice but to make a transition to Industry 4.0. It will be a major driver of development and differentiation for industrial equipment suppliers.

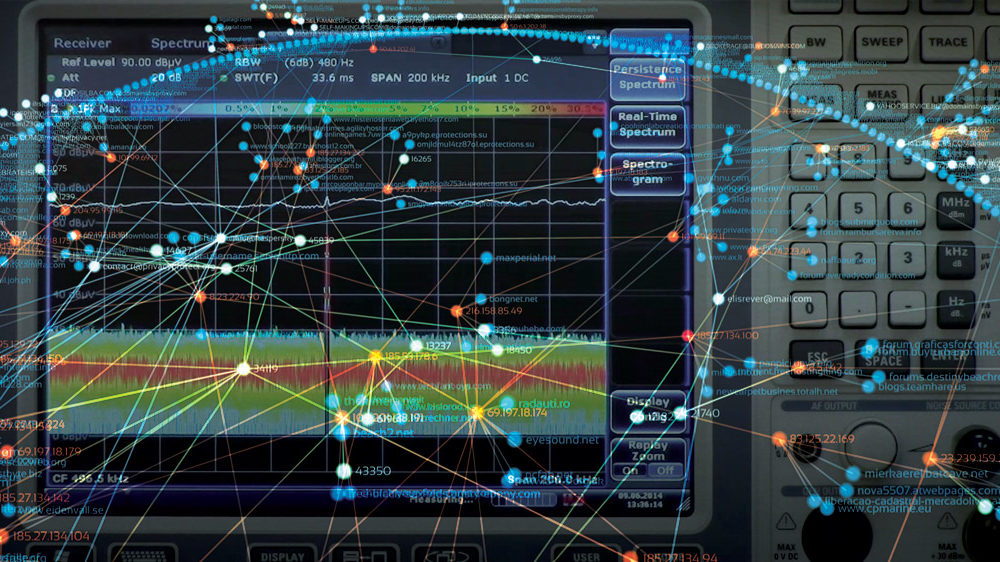

IoT and cloud computing

Today’s manufacturing industry is witnessing a rapid technological progress, along with factories integrating automation with smart devices; with the aim of facilitating data sharing and communication within the organisation. Meenu Singhal, VP Industry Business, Schneider Electric India, explains, “With the advent of Industry 4.0, the industry was introduced to several new components, the most significant being IoT. IoT and cloud computing brought a host of benefits which helped to improve the efficiency and functioning of organisations in the manufacturing sector. With information being made available across the organisation, this has helped in several factors including predictive maintenance, improved assembly line production and supply chain management.”

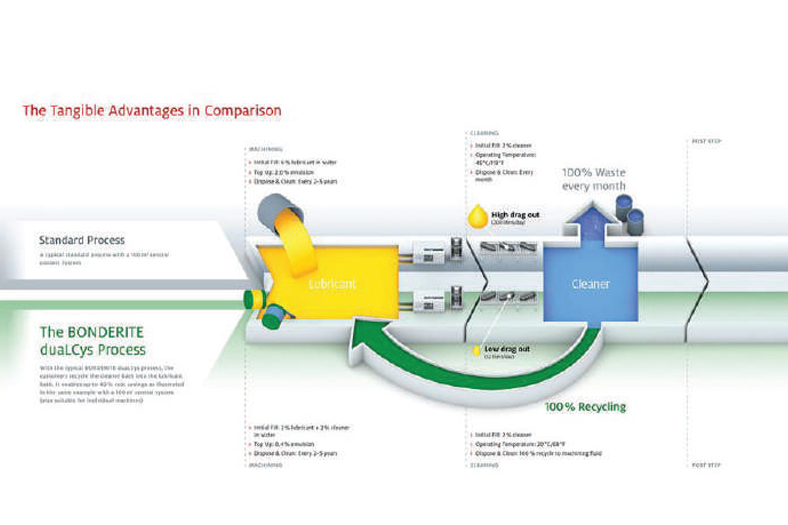

Save costs and ensure quality

Quality and highest standards of product performance are directly linked. Quality is a set of acceptable parameters that can be governed and controlled through accurate measurements. This calls for high resolution measurement along with automation. Ajey Phatak, Head Marketing, Beckhoff Automation, informs, “Measurement automation plays a significant role to maintain the highest standards and that too with require speed. Imagine a million mobiles phones getting produced and the demanding quality to be maintained at desired production speed. Automation in test and measurement parameters of products in mass production saves overall cost and ensures quality.”

A major factor of modern manufacturing

Automation in manufacturing has been transforming factory floors, the nature of manufacturing employment, and the economics of many manufacturing sectors. Manish Walia, Head-Industrial Automation Business Group, Delta Electronics India Pvt Ltd, says, “Test and measurement automation is becoming the defining factor of modern manufacturing. Though manufacturing is one of the most highly automated industries globally, there is still significant automation potential within the four walls of manufacturing sites, as well as in related functional areas such as supply chain and procurement.”

A new generation of robots that are more flexible and versatile, and cost far less than those used in many manufacturing environments today can be ‘trained’ by frontline staff to perform tasks previously thought to be too difficult for machines. Lastly, Walia adds, “Test automation helps application functions smoothly and when the functionality is tested regularly and frequently it plays a significant role in industry like manufacturing.”

Greater flexibility in the manufacturing process increases the value of products and improves margins.

Varun Arora, National Sales Manager, Exor India Pvt Ltd

IoT and cloud computing brought a host of benefits which helped to improve the efficiency and functioning of organisations in the manufacturing sector.

Meenu Singhal, VP Industry Business, Schneider Electric India

Automation in test and measurement parameters of products in mass production saves overall cost and ensures quality.

Ajey Phatak, Head Marketing, Beckhoff Automation

Test and measurement automation is becoming the defining factor of modern manufacturing.

Manish Walia, Head-Industrial Automation Business Group, Delta Electronics India Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi